Method for treating waste water of aquatic bird cultivation through utilizing microalgae

A water poultry breeding wastewater and microalgae technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve a high comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

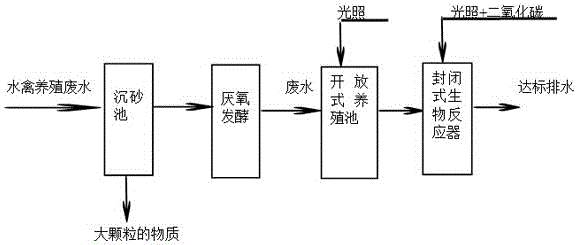

[0026] S1. Put the waterfowl breeding wastewater into the grit chamber for sedimentation to remove large particles;

[0027] S2. Put the sedimented waterfowl breeding wastewater into an anaerobic tank for fermentation, the pH value is controlled at 6.0, the temperature is 25°C, the rotation speed of the agitator is 100rmp, and the fermentation time is 24 hours;

[0028] S3. Putting the waterfowl breeding wastewater through anaerobic fermentation into an open breeding pond to inoculate Chlorella pyrenoidesa and carry out open cultivation; wherein, the inoculation amount of Chlorella pyrenoidosa is 15% of the waterfowl breeding wastewater volume; pH is controlled The value is 6.0, the temperature is 25°C, the light intensity is 2500lx, and the culture time is 2d;

[0029] S4. Put the waterfowl breeding waste water treated in step S3. into a closed bioreactor, and feed carbon dioxide to continue the reaction; control the volume fraction of carbon dioxide in the air in the closed ...

Embodiment 2

[0032] S1. Put the waterfowl breeding wastewater into the grit chamber for sedimentation to remove large particles;

[0033] S2. Put the sedimented waterfowl breeding wastewater into an anaerobic tank for fermentation, the pH value is controlled at 5.0, the temperature is 20°C, the rotation speed of the agitator is 50rmp, and the fermentation time is 12 hours;

[0034] S3. Putting the water fowl breeding waste water through anaerobic fermentation into an open culture pond to inoculate Chlorella pyrenoidesa and carry out open culture; wherein, the inoculation amount of Chlorella pyrenoidosa is 10% of the water fowl breeding waste water volume; control pH The value is 7.0, the temperature is 32°C, the light intensity is 2000lx, and the culture time is 1d;

[0035] S4. Put the waterfowl breeding waste water processed through step S3. into a closed bioreactor, and feed carbon dioxide to continue the reaction; control the volume fraction of carbon dioxide in the air in the closed b...

Embodiment 3

[0038] S1. Put the waterfowl breeding wastewater into the grit chamber for sedimentation to remove large particles;

[0039] S2. Put the sedimented waterfowl breeding wastewater into an anaerobic tank for fermentation, the pH value is controlled at 8.0, the temperature is 30°C, the rotation speed of the agitator is 200rmp, and the fermentation time is 24 hours;

[0040] S3. Putting the water fowl breeding waste water through anaerobic fermentation into an open culture pond to inoculate Chlorella pyrenoidesa and carry out open culture; wherein, the inoculation amount of Chlorella pyrenoidosa is 20% of the water fowl breeding waste water volume; control pH The value is 7.0, the temperature is 32°C, the light intensity is 3000lx, and the breeding time is 3 days;

[0041] S4. Put the waterfowl breeding waste water treated in step S3. into a closed bioreactor, and feed carbon dioxide to continue the reaction; control the volume fraction of carbon dioxide in the air in the closed bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com