Biological pollution resistant material and preparation method thereof

An anti-biological pollution, hydrophilic polymer technology, applied in the field of materials science, can solve problems such as unfavorable inhibition of protein adsorption and bacterial adhesion, and difficulty in further improving PEG surface coverage, so as to inhibit bacterial adhesion and improve surface coverage. , the effect of inhibiting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

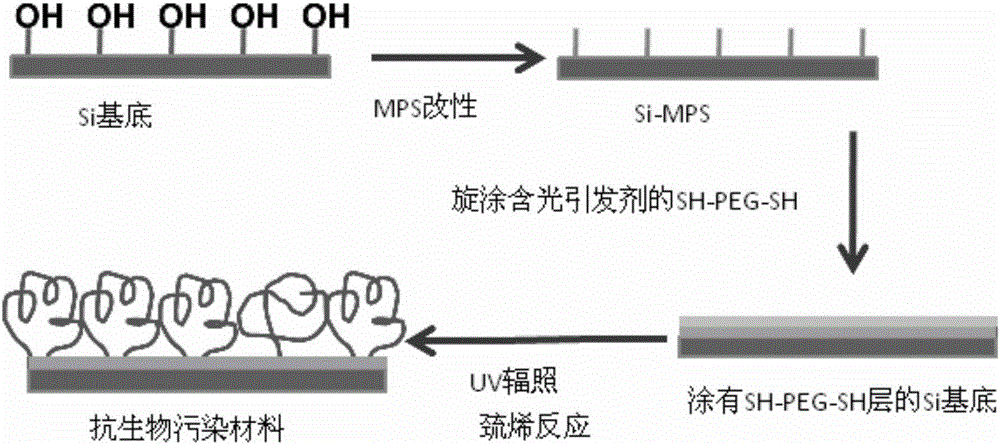

[0065] The present invention also provides a kind of preparation method of anti-biological pollution material, comprises the following steps:

[0066] The surface of the substrate is grafted with both ends of the double-end hydrophilic polymer to obtain an anti-biological pollution material; the two end groups of the double-end hydrophilic polymer are independently selected from sulfhydryl, amino, NHS-, carboxyl or sulfonic acid groups.

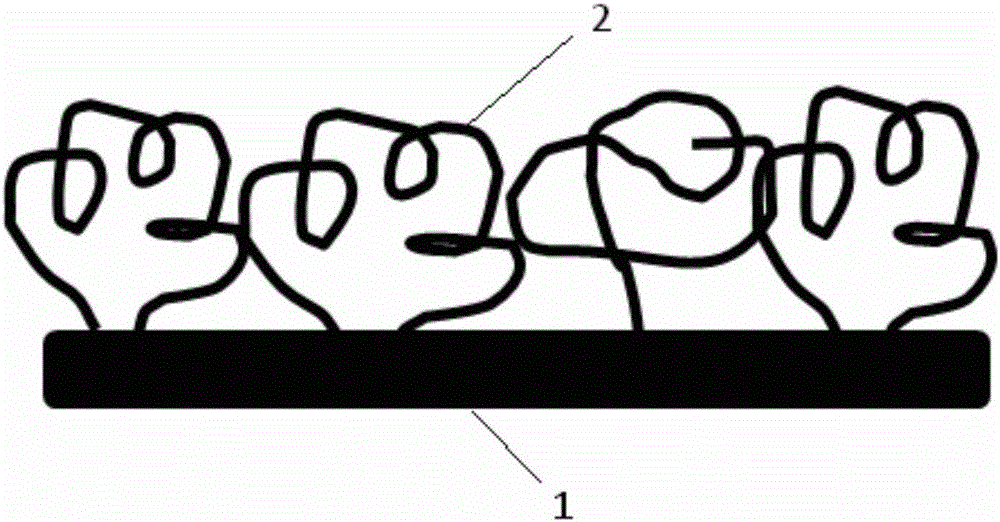

[0067] The present invention provides a new idea for constructing a system for inhibiting biological pollution. The present invention adopts a simple and feasible two-end grafting modification method, and does not require complex synthesis techniques to prepare ring-shaped hydrophilic polymers on the surface of different substrates. The structural layer, that is, the anti-biofouling coating is constructed on the surface of different substrates, thereby preparing a new type of anti-biofouling material with low protein adsorption and anti-bacte...

Embodiment 1

[0096] Dissolve 10 mg of SH-PEG5000-SH (purchased from Shanghai Yanyi Biology, with a number average molecular weight of 5000) in 10 mL of PBS solution to prepare a PEG solution with a concentration of 1 mg / mL. Filtered to remove impurities and bacteria.

[0097] Set the experimental temperature at 20.0±0.1°C, first use PBS buffer to flow through the sample cell of the quartz crystal microbalance (QCM-D) to perform baseline calibration, and after the temperature and baseline are stable, the PEG is injected at a rate of 100 μL / min. The solution was passed on the surface of the QCM-D gold chip for 10 minutes, at which time the PEG molecular chains had been grafted and fixed to the chip surface through sulfur-gold bonds, and then the physically adsorbed PEG molecular chains were washed away with PBS to obtain anti-biological contamination materials.

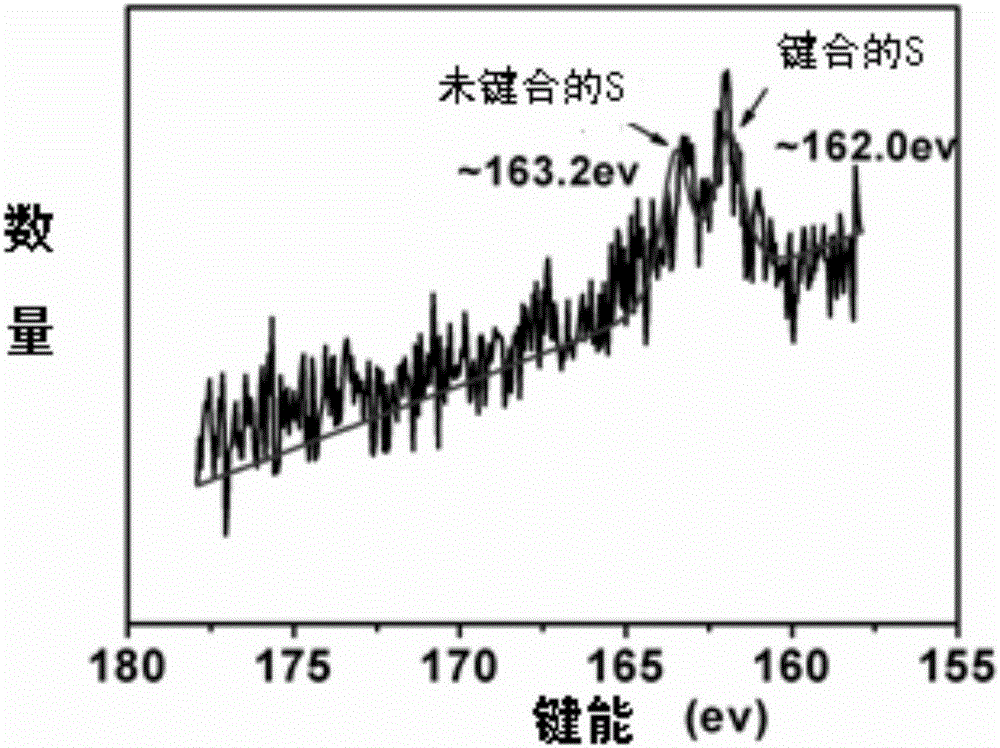

[0098] Use VGESCALABMKII type X-ray photoelectron spectrometer (XPS) to analyze the surface elements of the sample before and afte...

Embodiment 2

[0102] Dissolve 10 mg of SH-PEG5000 (purchased from Shanghai Yanyi Biology) and SH-PEG5000-SH (purchased from Shanghai Yanyi Biology) in 10 mL of PBS solution to prepare a 1 mg / mL PEG solution.

[0103] Set the experimental temperature at 20.0±0.1°C, firstly use PBS buffer to flow through the sample cell of quartz crystal microbalance (QCM-D) for baseline calibration, and after the temperature and baseline are stable, transfer all the samples at a speed of 100 μL / min The above-mentioned PEG solution was introduced into the surface of the QCM-D gold chip for 10 min. At this time, the PEG molecular chains had been grafted and fixed to the chip surface through the sulfur-gold bond, and then the physically adsorbed PEG molecular chains were washed away with PBS respectively to obtain monothiol PEG grafts. Branched material and bis-mercapto PEG grafted material.

[0104] After the baseline was stable, the PBS solution of fibrinogen (Fib) was passed through at the same speed for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com