High-temperature-resistant EPDM (ethylene-propylene-diene monomer) sealing material

A sealing material, high temperature resistant technology, applied in the field of sealing materials, to achieve high elongation at break, not easy to migrate, and good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

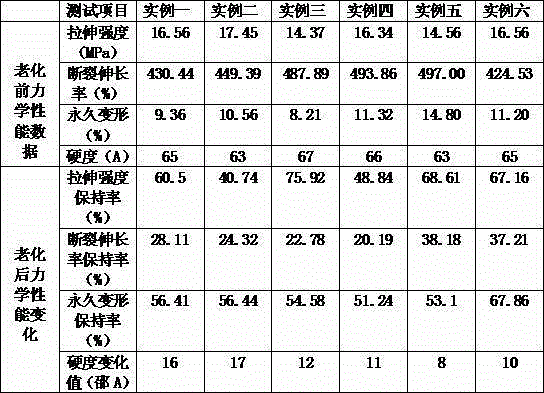

[0020] Example 1: Put 100g of EPDM4045 thin pass on the double-roll mill, then add 4g of activator zinc oxide, 2g of magnesium oxide, 1g of stearic acid, and reactive anti-aging agent N-4( Anilinophenyl) maleimide (MC) 2g, reinforcing carbon black N330, N550 respectively 30g, 30g, polyisobutylene (PIB) 10g, finally add vulcanizing agent peroxidation and cumene (DCP) 2.5g , uniformly mixed on an open mill to obtain the mixed rubber, and then vulcanized on a 160°C flat plate to obtain vulcanized rubber. After punching the film, measure its mechanical properties, then place the film in an aging box at 175°C for aging, take it out after 96h and measure again Its mechanical properties are shown in Table 1.

example 2

[0021] Example 2: Put 100g of EPDM4045 thin pass on the double-roll mill, then add 4g of activator zinc oxide, 2g of magnesium oxide, 1g of stearic acid, and reactive anti-aging agent N-4( Anilinophenyl) maleimide (MC) 2g, reinforcing carbon black N330, N550 respectively 30g, 30g, polyisobutylene (PIB) 10g, finally add vulcanizing agent peroxidation and cumene (DCP) 2.5g and sulfur (S) 0.1g, uniformly mixed on the open mill to obtain the mixed rubber, and then vulcanized on a plate at 160°C to obtain the vulcanized rubber, measured its mechanical properties after punching, and then placed the film in an aging box at 175°C for aging. Take it out after 96 hours and measure its mechanical properties again, see Table 1.

example 3

[0022] Example 3: Put 100g of EPDM4045 thin pass on the double-roll mill, then add 4g of activator zinc oxide, 2g of magnesium oxide, 1g of stearic acid, and reactive anti-aging agent N-4( Anilinophenyl) maleimide (MC) 2g, reinforcing carbon black N330 and N550 respectively 30g and 30g, polyisobutylene (PIB) 10g, and finally add vulcanizing agent bis-tert-butyl peroxide diisopropylbenzene (BIPB) 4.2g, uniformly mixed on the open mill to obtain the mixed rubber, and then vulcanized on a plate at 170°C to obtain vulcanized rubber, measured its mechanical properties after punching, and then aged the film in an aging box at 175°C, after 96h Take it out and measure its mechanical properties again, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com