Synthesis process of nanometer macromolecule ecological wood

A nano-polymer and synthetic process technology, applied in the field of nano-polymer ecological wood synthesis process, can solve problems such as poor weather resistance and poor ultraviolet adaptability, and achieve the effect of solving polar differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

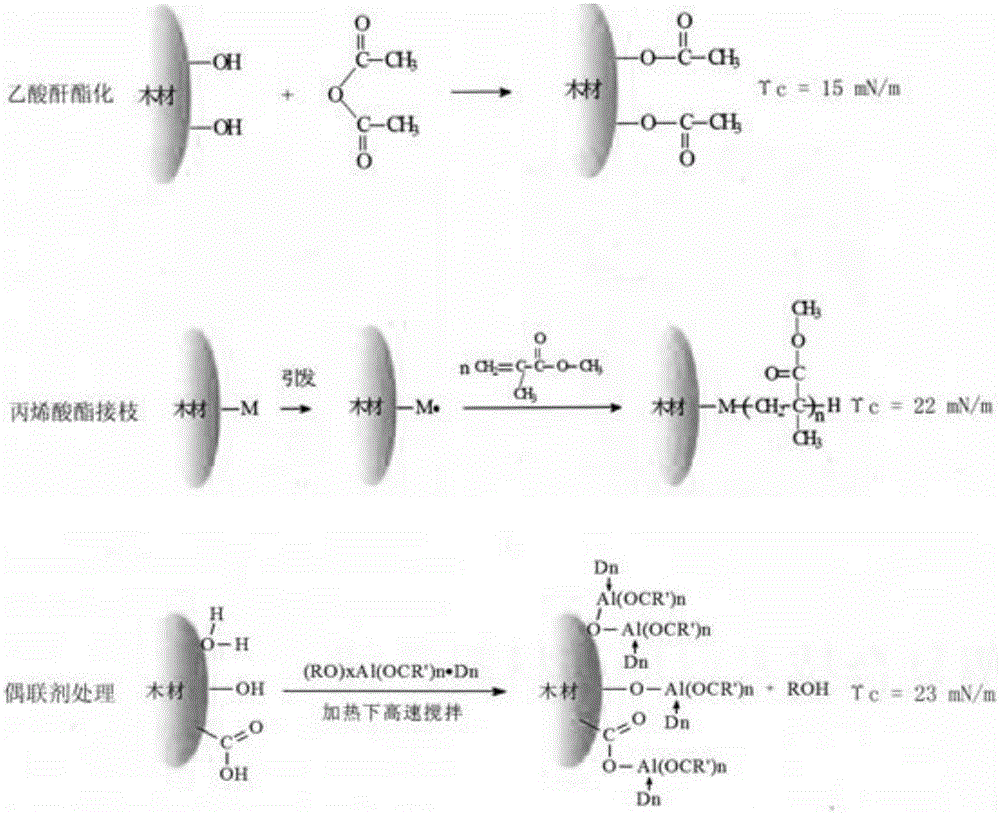

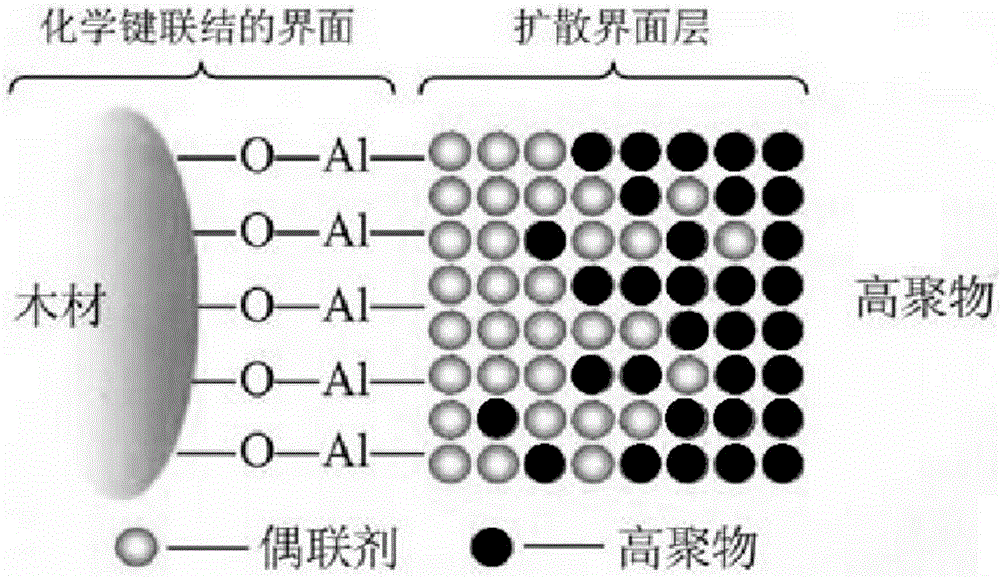

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] Such as figure 1 and figure 2 Shown: the composition of nano macromolecule ecological wood of the present invention is by wood powder 40%-60%, macromolecule resin powder 25%-35%, nano-scale light calcium 8%-10%, coupling agent 4%- 6%, release agent 3%-5%, silica powder 5%-6%, and aluminum oxide flame retardant 5%-8%.

[0020] Specifically, 60% of the wood powder, 15% of the polymer resin powder, 10% of the nano-scale light calcium, 3% of the coupling agent, 2% of the release agent, and 5% of the silicon micropowder %, the described aluminum oxide flame retardant 5%. The coupling agent is a silane coupling agent; the release agent is SI-193 water-soluble silicone oil; the silicon micropowder is powdered natural quartz.

[0021] Release agent: high polymer material emulsified concentrate, SI-193 water-soluble silicone oil is mainly silane components (polysilicone)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com