Production technology of potato vinegar

A production process, potato technology, applied in the field of vinegar production process, can solve the problems of less research and poor product quality, and achieve the effect of high aroma components, sufficient aftertaste, and improved esterification level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

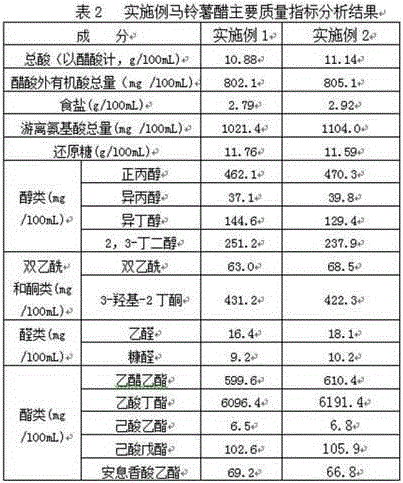

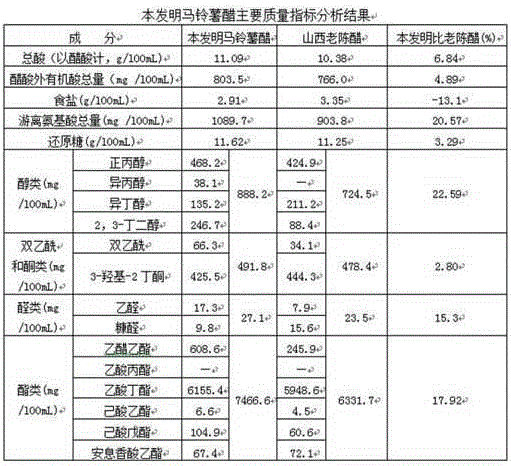

Examples

Embodiment 1

[0046] The production technology of potato vinegar comprises the steps:

[0047] (1) Select raw materials that are disease-free and rotten, and the diameter of the potato pieces is 7-8 cm. 90 kg of potatoes produced in Hekou Township, Lanxian County. The millet and sorghum are removed from impurities, mildew and rotten raw materials, and then the millet, The sorghum is shelled first, and then crushed into 10-20 mesh particles. Take 6 kg of shelled millet and 4 kg of shelled sorghum.

[0048] (2) Moisturizing Soak the potatoes prepared in (1) with 450 kg of drinking water for 12 hours, then repeatedly wash and remove all impurities on the surface of the skin, remove and dry; Add 5 kg of water at 75-80°C to the shell sorghum to moisten the material, stir slowly and evenly, put it into a wooden tank or vat, and let it rest for 8 hours to moisten the material. During the moistening period, keep the temperature of the material at 30-35°C. The quality of the moistening material req...

Embodiment 2

[0062] The production technology of potato vinegar comprises the steps:

[0063] (1) Select raw materials that are disease-free and rotten, and the diameter of potato pieces is 7-8 cm. 92 kg of potatoes produced in Hekou Township, Lanxian County. The millet and sorghum are removed from impurities, mildew and rotten raw materials, and then the millet, The sorghum is shelled first, and then crushed into 10-20 mesh particles. Take 6.2 kg of shelled millet and 4.2 kg of shelled sorghum.

[0064] (2) Moisturizing Soak the potatoes prepared in (1) with 460 kg of drinking water for 12 hours, then repeatedly wash and remove all impurities on the surface of the skin, remove and dry; Add 6.2kg of water at 75-80°C to the shell sorghum to moisten the material, stir slowly and evenly, put it into a wooden tank or vat, and let it rest for 12 hours to moisten the material. During the moistening period, keep the temperature of the material at 30-35°C. The quality of the moistening material r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com