A low-temperature scouring agent, its preparation method and its use

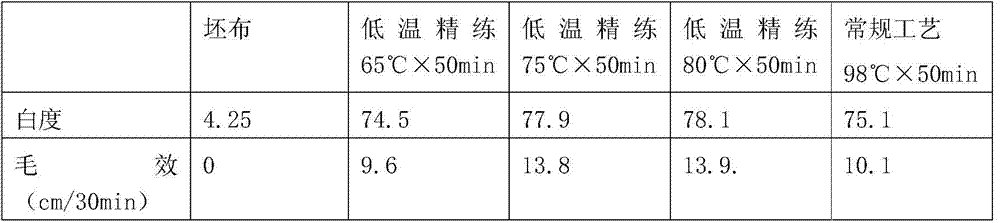

A scouring agent and low temperature technology, applied in biochemical fiber treatment, textile and papermaking, fiber treatment, etc., can solve the problems of high fabric weight loss rate, long time consumption, high COD value, etc., to reduce fabric weight loss rate and strong damage, and shorten the process time, the effect of reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

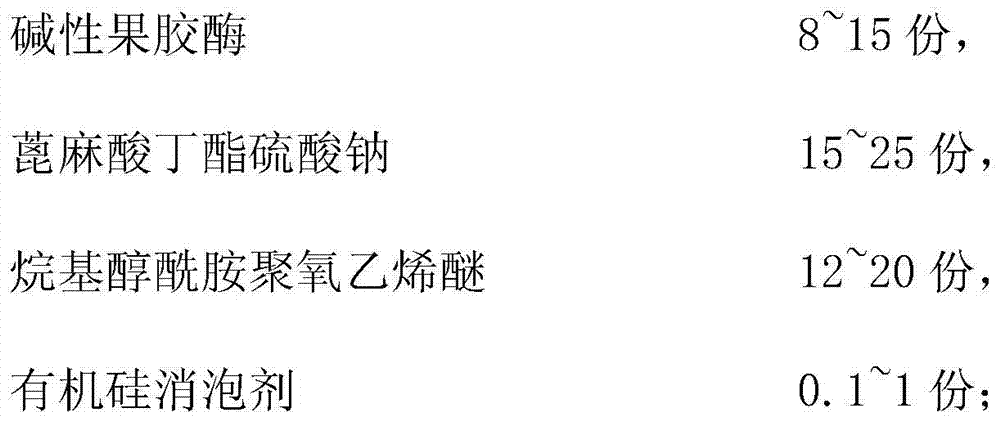

[0034] The low-temperature bleaching agent consists of the following components by weight: 8 parts of alkaline pectinase, 15 parts of sodium butyl ricinoleate sulfate, 12 parts of C8 alcohol amide polyoxyethylene ether (3EO), 0.1 parts of silicone defoamer share;

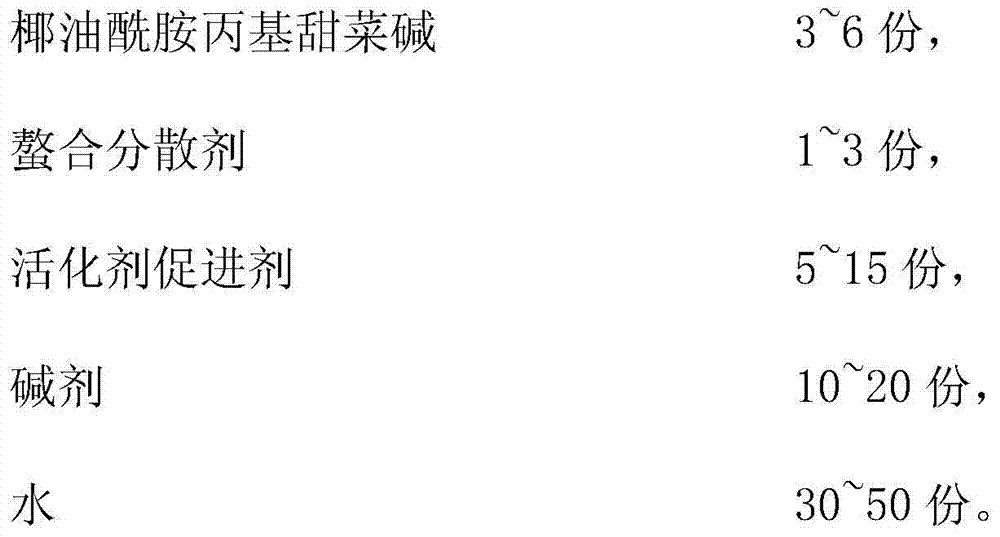

[0035] The low-temperature oxygen bleaching activator consists of the following components by weight: 3 parts of cocamidopropyl betaine, 1 part of acrylic acid maleic anhydride graft, 5 parts of N-methylformamide, 10 parts of sodium hydroxide, 30 parts of water share.

[0036] The low-temperature scouring agent component consists of 15% by mass of low-temperature scouring agent and 85% by mass of low-temperature oxygen bleach activator.

[0037] Described low-temperature scouring agent is used for the low-temperature scouring process of cotton / wool blended yarn, carries out according to the following steps:

[0038] S1: Use the bath ratio of 1:10, add fabric, 30% hydrogen peroxide 3g / l, low-temperature oxygen blea...

Embodiment 2

[0047] The low-temperature bleaching agent is composed of the following components by weight: 10 parts of alkaline pectinase, 19 parts of sodium butyl ricinoleate sulfate, 16 parts of C18 alcohol amide polyoxyethylene ether (6EO), 0.4 parts of silicone defoamer share;

[0048] The low-temperature oxygen bleaching activator consists of the following components by weight: 4 parts of cocamidopropyl betaine, 2 parts of acrylic acid maleic anhydride grafts, 10 parts of N-methylformamide, 12 parts of sodium hydroxide, 35 parts of water share.

[0049] The low-temperature scouring agent component consists of 20% by mass of low-temperature scouring agent and 80% by mass of low-temperature oxygen bleach activator.

Embodiment 3

[0064] The low-temperature bleaching agent is composed of the following components by weight: 15 parts of alkaline pectinase, 25 parts of sodium butyl ricinoleate sulfate, 12 parts of C12 alcohol amide polyoxyethylene ether (4EO), 1 part of silicone defoamer share;

[0065] The low-temperature oxygen bleaching activator is composed of the following components by weight: 6 parts of cocamidopropyl betaine, 3 parts of acrylic acid maleic anhydride graft, 15 parts of N-methylformamide, 20 parts of sodium hydroxide, 50 parts of water share.

[0066] The low-temperature scouring agent component consists of 25% by mass of low-temperature scouring agent and 75% by mass of low-temperature oxygen bleach activator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com