Dyeing and finishing method for linen for child's vest

A linen and vest technology, applied in the field of dyeing and finishing, can solve the problems affecting fabric quality, heavy pigment, easy to wrinkle, etc., and achieve the effects of improving dyeing brightness, reducing impurity content, and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following specific examples further illustrate the present invention.

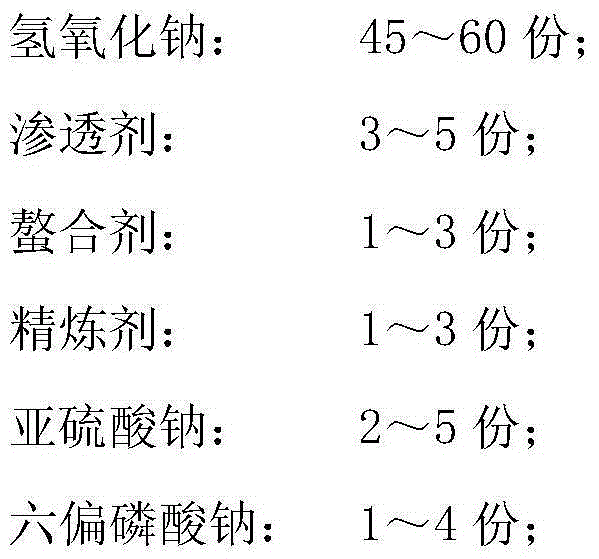

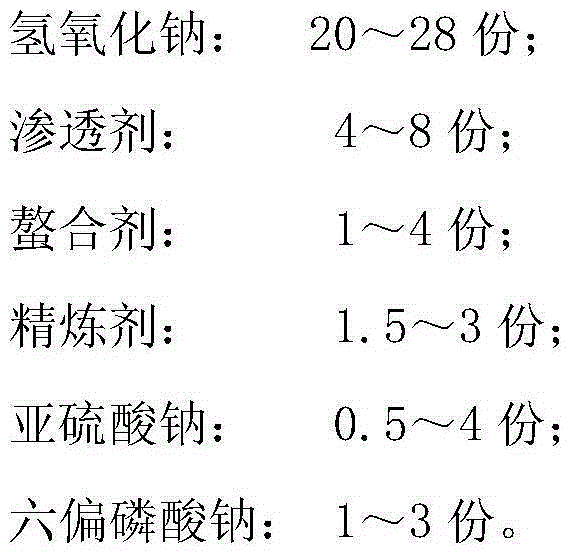

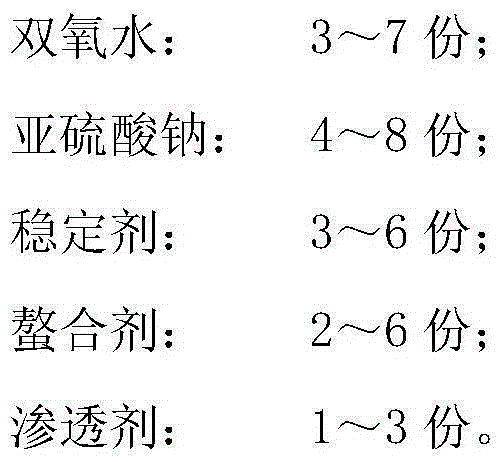

[0035] The dyeing and finishing method of linen for children's vests of the present invention comprises the following steps:

[0036] (1) Raw fabric preparation: gray fabric specification→grain fabric inspection→turning cloth→printing→sew head; the gray fabric width: 160cm, linear density warp and weft yarns are 39tex, warp and weft density 197 / 10cm×212 / 10cm,

[0037] Seam head: seam head density, using 42 pairs of waxed cotton thread,

[0038] The stitch density is 26~30 stitches / 10cm, the two ends are encrypted 1.5~2cm, and the natural length of the trailing tail is 3~5cm;

[0039] (2) Singeing and rolling oxalic acid solution: feeding cloth → brushing → singeing → padding oxalic acid → falling cloth and rolling;

[0040] The cloth feeding speed is 80 / min;

[0041] The flame temperature of singeing is 800℃, two positive and two negative;

[0042] The concentration of padding oxalic acid is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com