Measuring method and device of spectrometer while drilling for measuring oil and gas composition

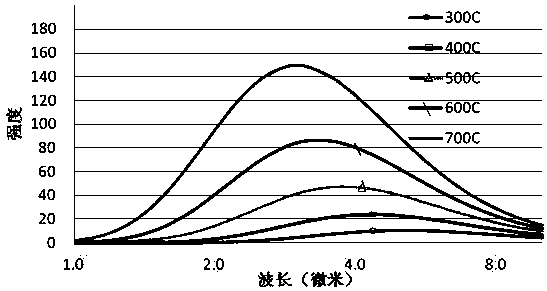

A measurement method and spectrometer technology, applied in the field of optical systems, can solve the problems of unsystematic long-term stability performance testing of new devices, maximum operating temperature of 60-80°C, and high cost of quantum cascade lasers, etc., and achieve a wide natural operating temperature range. , low power consumption, small cross-section effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

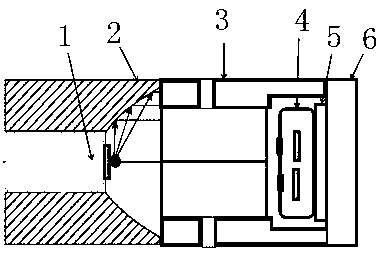

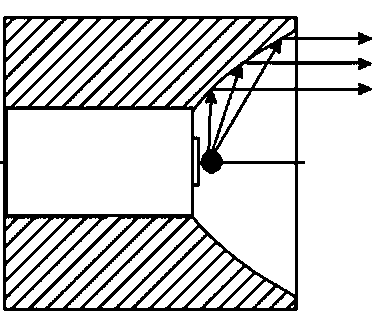

[0049] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a parabolic reflector that collimates the luminous point of the light source 1, and is characterized in that a sampling gas chamber, a reference gas chamber and a detector with four channels and four independent thermopiles are arranged behind the reflector, each Each channel is equipped with a filter and a transmission window, and the detector 4 is installed on a semiconductor cooling chip 5 . There are four passages in the cavity 3 of the sample gas chamber and the reference gas chamber. The installation base 6 is the installation base for installing the analyzer, and is also the cooling channel for the cooling fin.

[0050] The light source 1 is installed in the parabolic reflector 2, and its luminous point is located at the focus of the parabolic reflector, so that the emitted light can be effectively emitted in parallel to achieve collimation. The gas chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com