Compression type braking and retarding system for automobile engine

A car engine, compression technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex structure, large volume, heavy weight, etc., and achieve the effect of small volume, simple structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

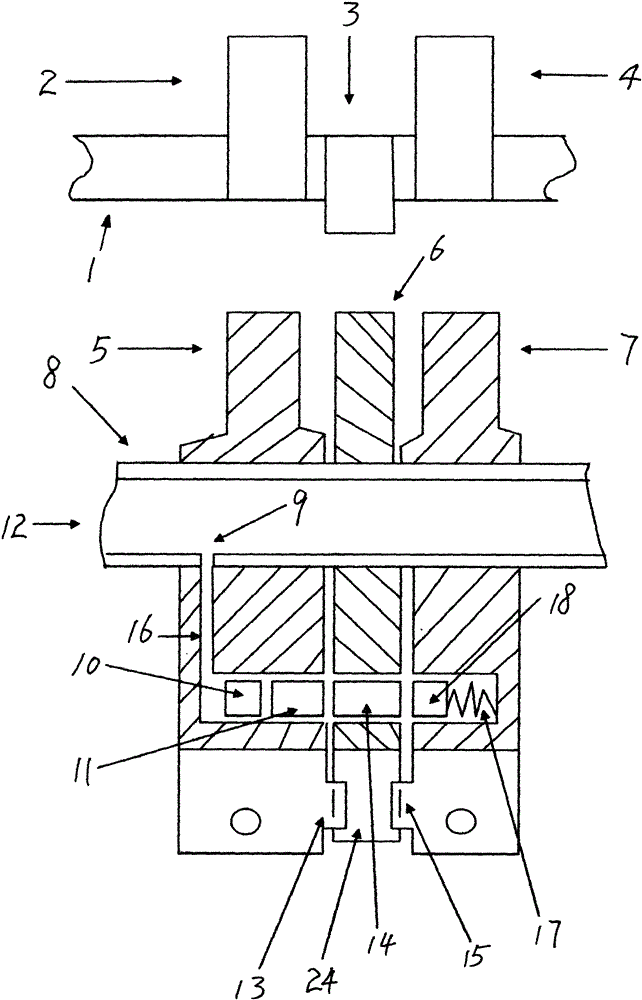

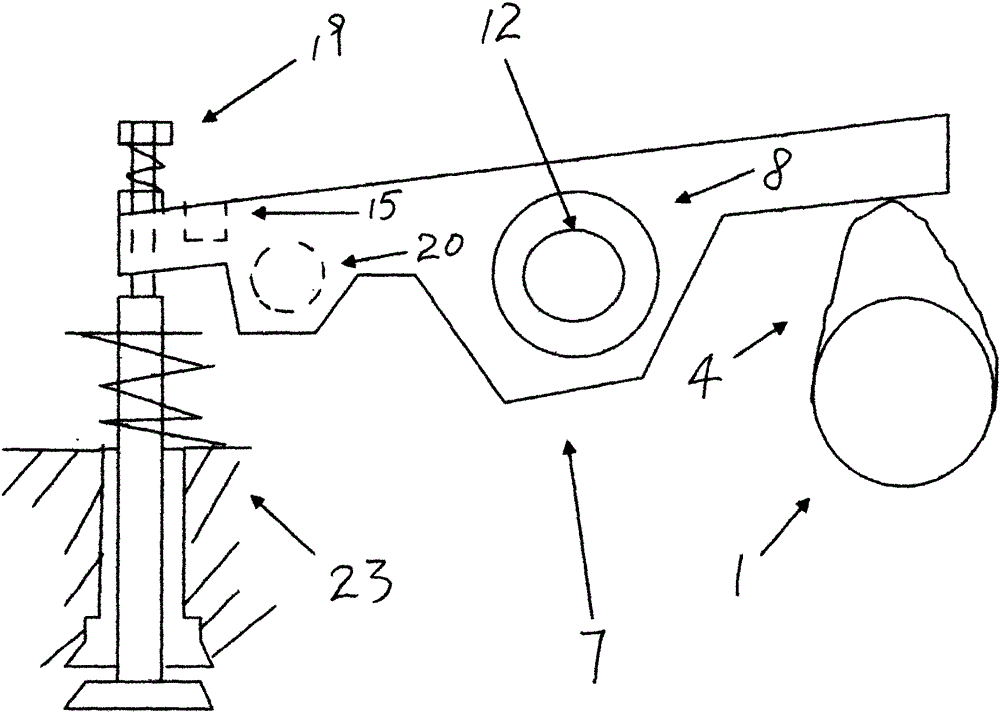

[0016] The automobile engine compression brake retarder system is composed of an overhead camshaft (1), a first exhaust valve rocker arm (5), a second exhaust valve rocker arm (7), a first adjusting screw (22), and a first exhaust valve rocker arm (7). Two adjustment screws (19), deflated rocker arm (6), positioning spring (26), timing piston (10), first synchronous piston (11), second synchronous piston (14), blocking piston (18), Blocking piston return spring (17), rocker shaft (8), oil pipe (32), solenoid valve (27), electric motor oil pump (33), pressure stabilizing valve (34), slow speed control circuit (31) form.

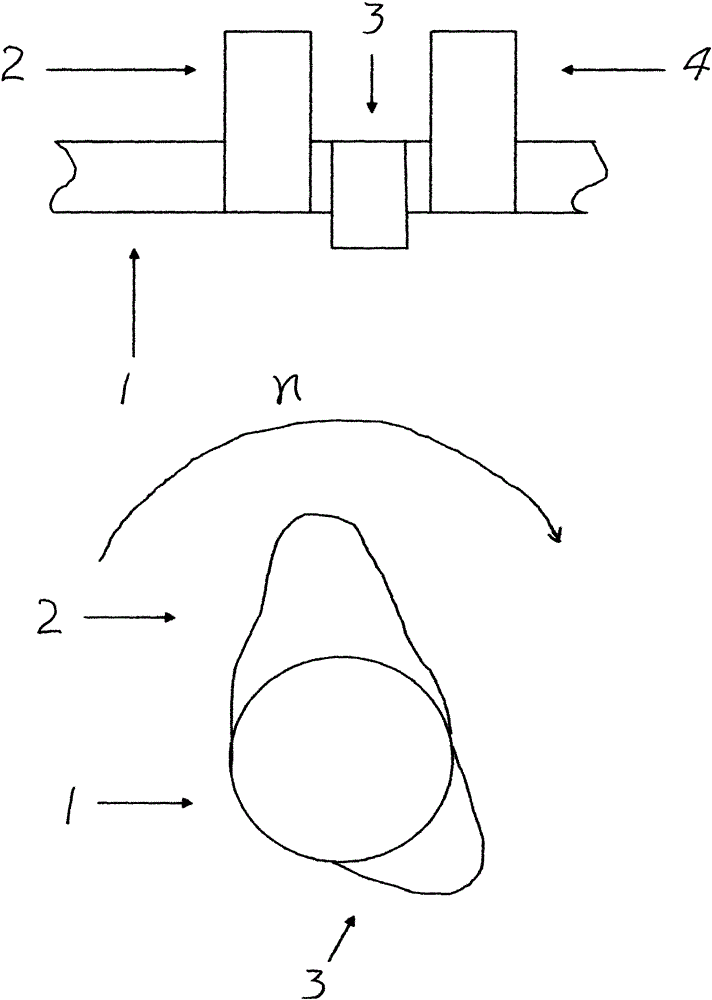

[0017] exist figure 1 , the camshaft (1) is provided with the first exhaust cam (2), the second exhaust cam (4) and the exhaust cam (3), and the rotation direction n indicates that the exhaust cam (4) is located near the end of the compression stroke corresponding position.

[0018] exist figure 2 Among them, the function of the first exhaust cam (2) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com