Mine cable and preparation method of cable sheath material

A cable sheathing material and cable technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of harsh use environment of cables and the inability of cables to meet the requirements of cable performance, so as to improve the anti-aging effect, shorten the vulcanization time, and improve the strength. and the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

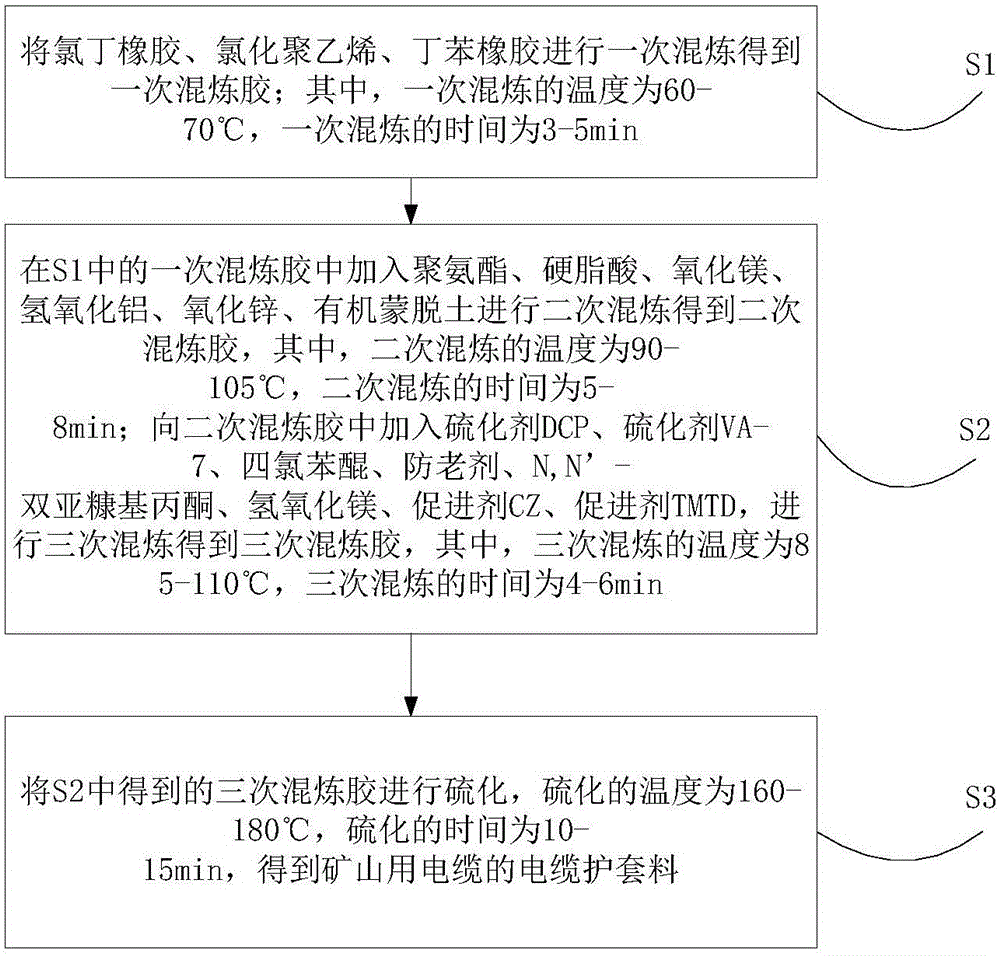

[0023] refer to figure 1 , the preparation method of the cable sheathing material of a kind of mine cable that the present invention proposes, comprises the steps:

[0024] S1. Mixing neoprene, chlorinated polyethylene, and styrene-butadiene rubber once to obtain a mixed rubber; wherein, the temperature of the first mixing is 60-70° C., and the time of the first mixing is 3-5 minutes;

[0025] S2. Add polyurethane, stearic acid, magnesium oxide, aluminum hydroxide, zinc oxide, and organic montmorillonite to the primary mixing rubber in S1 for secondary mixing to obtain a secondary mixing rubber, wherein the secondary mixing The temperature is 90-105℃, and the time for secondary mixing is 5-8min; add vulcanizing agent DCP, vulcanizing agent VA-7, tetrachlorobenzoquinone, anti-aging agent, N,N'- Double furfurylidene acetone, magnesium hydroxide, accelerator CZ, and accelerator TMTD are mixed three times to obtain three mixed rubbers, wherein the temperature of the third mixing ...

Embodiment 1

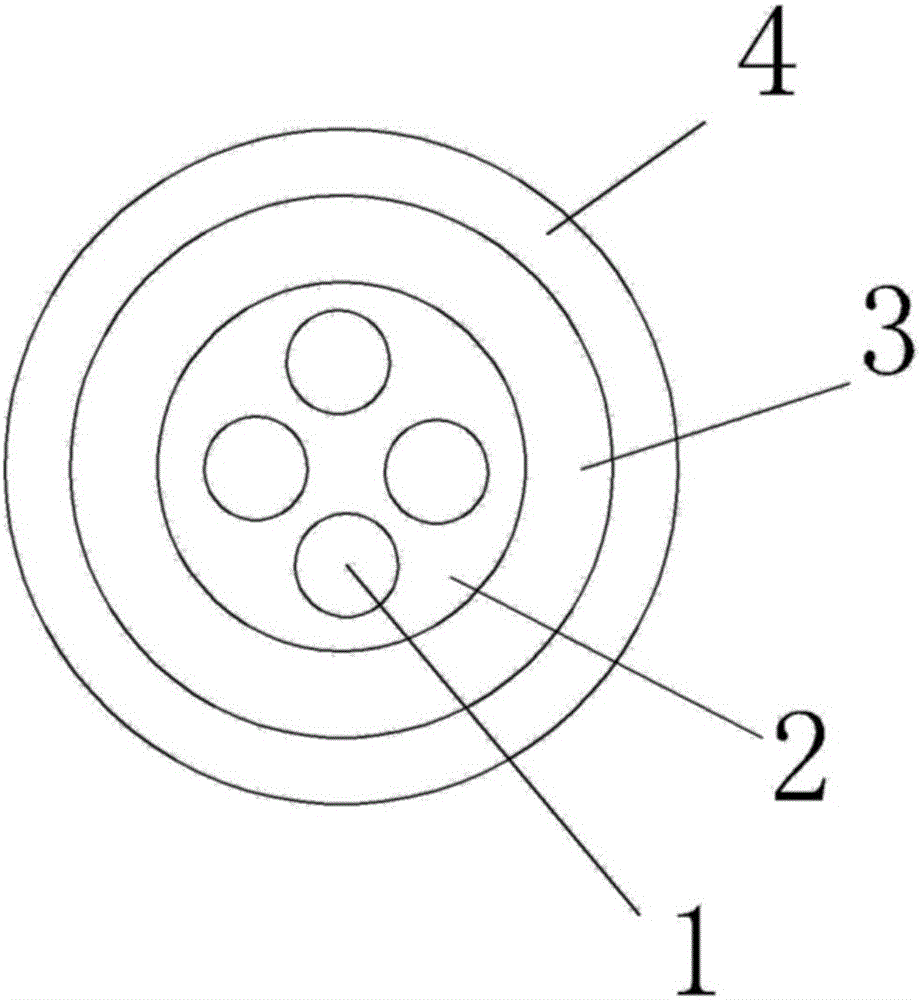

[0031] refer to figure 2 , a mine cable proposed by the present invention comprises a cable core 1, an insulating layer 2, a buffer layer 3 and a sheath layer 4, the outer periphery of the cable core 1 is covered with an insulating layer 2, and the outer periphery of the insulating layer 2 is covered with a buffer Layer 3, the outer periphery of buffer layer 3 is coated with sheath layer 4, and the raw material of sheath layer 4 comprises by weight: 60 parts of neoprene rubber, 30 parts of chlorinated polyethylene, 13 parts of styrene-butadiene rubber, 4 parts of polyurethane, 2.0 parts of stearic acid, 1.0 parts of magnesium oxide, 11 parts of aluminum hydroxide, 3.0 parts of zinc oxide, 3.0 parts of organic montmorillonite, 3.5 parts of vulcanizing agent DCP, 76 parts of vulcanizing agent VA-76, 3.5 parts of chlorobenzoquinone, 0.9 parts of anti-aging agent, 2.5 parts of N,N'-bisfurylidene acetone, 1.0 parts of magnesium hydroxide, 0.8 parts of accelerator CZ, and 0.7 parts...

Embodiment 2

[0037] refer to figure 2 , a mine cable proposed by the present invention comprises a cable core 1, an insulating layer 2, a buffer layer 3 and a sheath layer 4, the outer periphery of the cable core 1 is covered with an insulating layer 2, and the outer periphery of the insulating layer 2 is covered with a buffer Layer 3, the outer periphery of buffer layer 3 is coated with sheath layer 4, and the raw material of sheath layer 4 comprises by weight: 55 parts of neoprene rubber, 35 parts of chlorinated polyethylene, 10 parts of styrene-butadiene rubber, 5 parts of polyurethane, 1 part of stearic acid, 1.2 parts of magnesium oxide, 8 parts of aluminum hydroxide, 5 parts of zinc oxide, 1 part of organic montmorillonite, 6 parts of vulcanizing agent DCP, 3 parts of vulcanizing agent VA-73, 5 parts of chlorobenzoquinone, antioxidant 0.5 parts, 3 parts of N,N'-bisfurylidene acetone, 0.5 parts of magnesium hydroxide, 1.3 parts of accelerator CZ, and 0.2 parts of accelerator TMTD.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com