Plant and system for the automatic horizontal assembly of photovoltaic panels with front-back connection of the cells and pre-fixing

An automatic assembly, photovoltaic panel technology, applied in the direction of photovoltaic power generation, photovoltaic modules, circuits, etc., can solve the problems of economic waste, affect the electrical performance of the panel, not suitable for traditional H-type cells, etc., to achieve high production volume, great technological progress and Practicality, high part positioning and fixation accuracy and effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

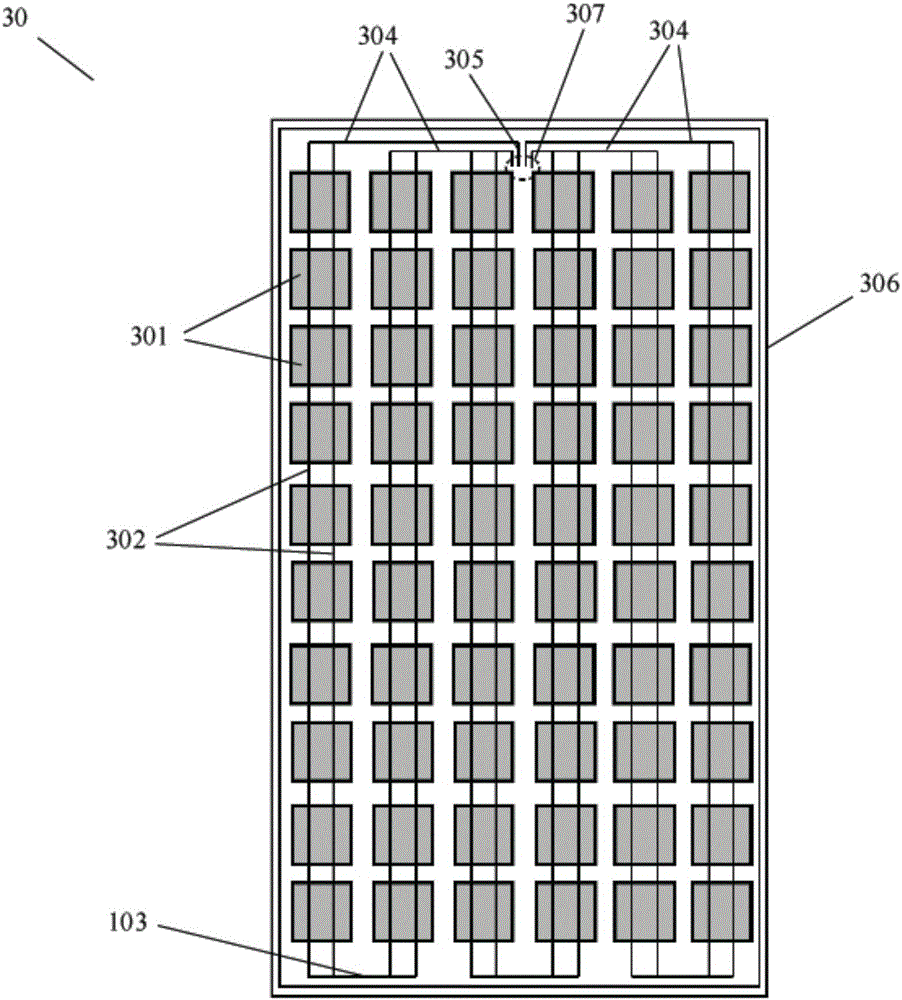

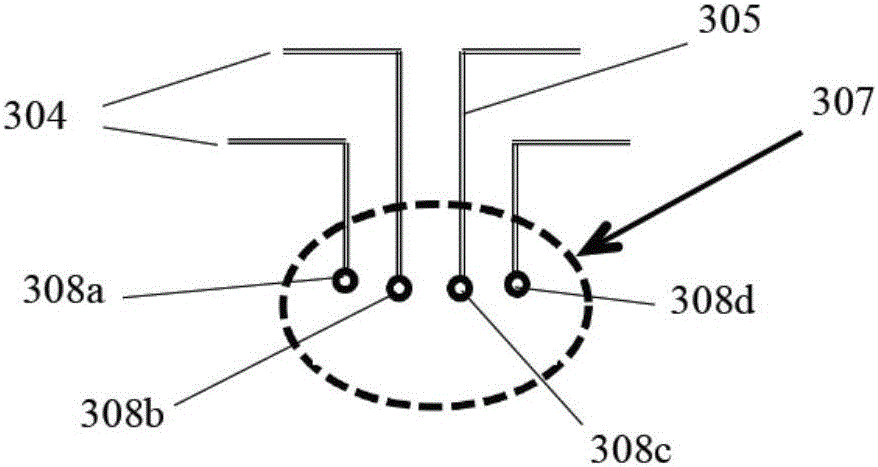

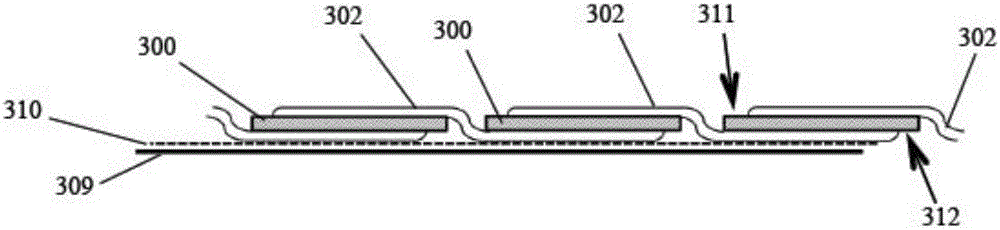

[0068] The present invention describes an innovative device 10 ( Figure 5a -b, 6a-d) comprising a modular operating station 100A-I for the automated assembly of photovoltaic panels 30 of conventional architecture from H-type front and rear contact solar cells; thus, the present invention presents a level of innovation type assembly system, which is based on a specific production method 20 optimized in the function of the device 10 ( Figure 7 , 8a -b), which solves the problems of conventional systems for assembling and stringing cells, and also allows high throughput, high positioning accuracy, and fixed parts. In particular, the invention provides that, according to the practice of the electronics industry, the cells are connected on both sides at low temperatures in an automatic manner by means of a limited amount of conductive adhesive placed on time; moreover, it is desirable that the cells and all contacts The components are pre-fixed to the layer of encapsulation mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com