Core-shell polyphenol surface finish collagen polypeptide nanospheres and preparation method thereof

A technology of collagen polypeptide and surface modification, which is applied in the field of tanning waste-collagen reuse, can solve the problems of small adsorption capacity of heavy metal ions, limited wide application, difficult regeneration, etc., and achieves good application prospects, high promotion value, and easy The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

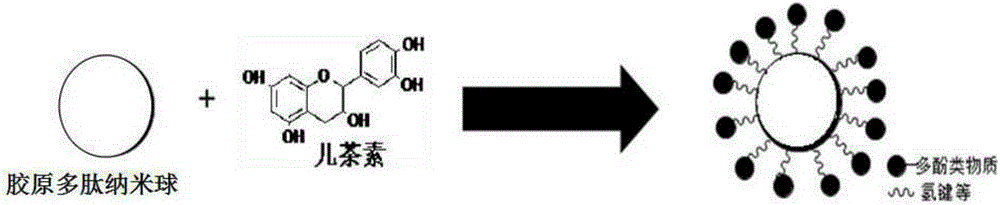

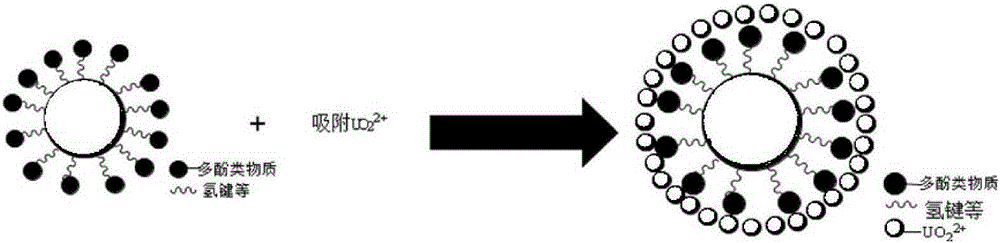

[0033] Step 1. Disperse 10.0 mg of collagen polypeptide nanospheres in 150 mL of distilled water, place on a magnetic stirrer, adjust the pH of the system to 5, slowly add 5 mg of catechol, stir for 5 hours at 25°C, and then raise the temperature to 40°C and stir for reaction 2h, centrifuge and separate to obtain solid particles; the stirring speed of the stirring reaction is 300r / min;

[0034] Step 2: Take 10.0 mg of solid particles and disperse them in 150 ml of distilled water, place them on a magnetic stirrer, add 0.3 mg of fatty alcohol polyoxyethylene ether-1, 1.0 mg of formaldehyde, stir and react at 25°C for 3 hours, heat up to 40°C and stir React for 2 hours, add 1mol.L -1 Adjust the pH to 6 with the HCl solution, let stand for 2 hours, centrifuge, and vacuum-dry at 50° C. to obtain core-shell polyphenol surface-modified collagen polypeptide nanospheres; the stirring speed of the stirring reaction is 300 r / min.

Embodiment 2

[0036] Step 1. Disperse 10.0 mg of collagen polypeptide nanospheres in 150 mL of distilled water, place on a magnetic stirrer, adjust the pH of the system to 5, slowly add 8 mg of catechin, stir for 5 hours at 25°C, and heat up to 40°C for 2 hours. , centrifuged and separated to obtain solid particles; the stirring speed of the stirring reaction is 500r / min.

[0037] Step 2: Take 10.0 mg of solid particles and disperse them in 150 mL of distilled water, place them on a magnetic stirrer, add 0.3 mg of fatty alcohol polyoxyethylene ether-2, 1.5 mg of glutaraldehyde, stir and react at 25°C for 3 hours, and heat up to 40°C °C and stirred for 2 hours, added 1mol.L -1 Adjust the pH of the HCl solution to 6, let it stand for 2 hours, centrifuge, and vacuum-dry at 50°C to obtain core-shell polyphenol surface-modified collagen polypeptide nanospheres; the stirring speed of the stirring reaction is 500r / min.

Embodiment 3

[0039] Step 1. Disperse 10.0 mg of collagen polypeptide nanospheres in 150 mL of distilled water, place on a magnetic stirrer, adjust the pH of the system to 5, slowly add 3 mg of bayberry extract, stir for 5 hours at 25°C, and heat up to 40°C for 2 hours. , centrifugation and separation; solid particles are obtained; the stirring speed of the stirring reaction is 400r / min.

[0040] Step 2: Take 10.0 mg of solid particles and disperse them in 150 mL of distilled water, place them on a magnetic stirrer, add 0.3 mg of fatty alcohol polyoxyethylene ether-S, 0.5 mg of epoxy resin, stir and react at 25°C for 3 hours, and heat up to 40°C °C and stirred for 2 hours, added 1mol.L -1 Adjust the pH to 6 with the HCl solution, let stand for 2 hours, centrifuge, and vacuum-dry at 50° C. to obtain core-shell polyphenol surface-modified collagen polypeptide nanospheres; the stirring speed of the stirring reaction is 400 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com