High-temperature-resisting carbon fiber reinforced composite continuous sucker rod and preparing device and method

A technology for reinforced composite materials and preparation devices, which is applied to drill pipes, drilling equipment, earthwork drilling, etc., can solve problems such as corrosion and partial wear, achieve excellent corrosion resistance and partial wear resistance, high production efficiency, increase radial and the effect of axial compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

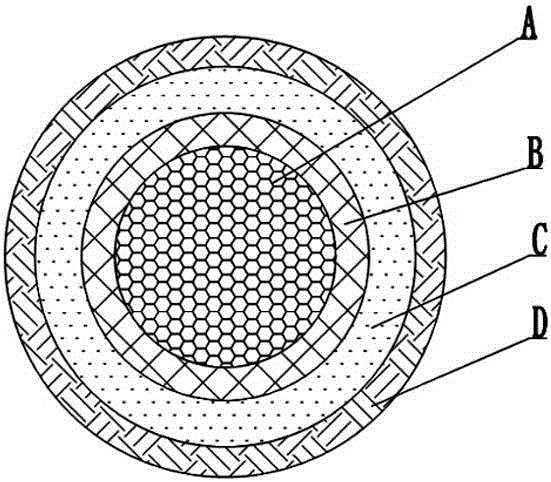

[0029] combined with figure 1 , a high-temperature-resistant carbon fiber reinforced composite material continuous sucker rod mentioned in the present invention, from the inside to the outside is the reinforcing fiber carbon fiber A along the rod body axial direction, and the fiber-wound reinforcement layer aramid 1414 fiber B; along the rod body axial direction Reinforcement fiber high-strength glass fiber C, fiber weaving reinforcement layer aramid 1414 fiber D, a layer of fiber-wound reinforcement layer aramid 1414 fiber B is wound on the outside of the reinforcement fiber carbon fiber A, and then covered by reinforcement fiber high-strength glass fiber C For pre-curing, use a braiding machine to weave a layer of fiber braided reinforcement layer aramid 1414 fiber D on the outer layer; finally inject multifunctional epoxy resin outside the outermost fiber braided reinforcement layer aramid 1414 fiber D, and the four-layer structure is cured at the same time Forming, its Tg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Cross angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com