A method for low-temperature crystallization of silicon oxide in a molten salt system

A technology for crystallization of silicon oxide and silicon oxide, applied in silicon oxide and other directions, can solve problems such as equipment damage and difficult quantification of reactions, and achieve the effects of reducing synthesis temperature, short reaction time and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

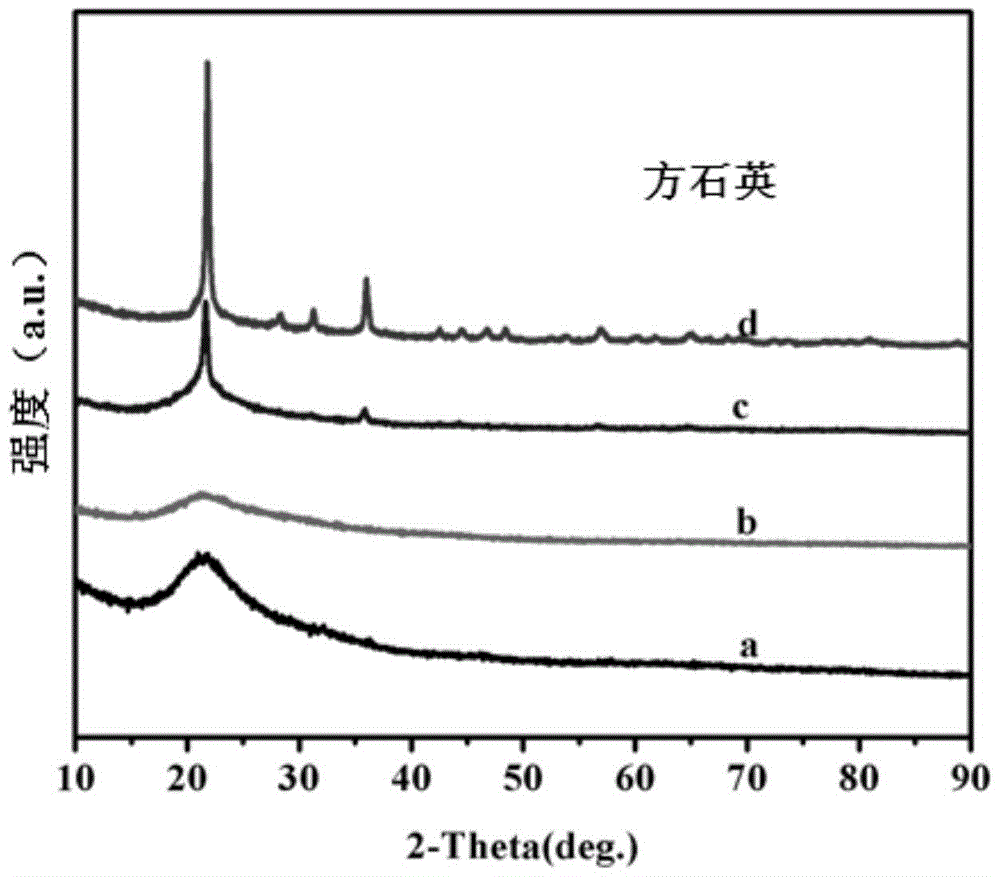

[0025] Press molten salt NaNO 3 , Accurately weigh 10.0g for grinding, take uncalcined mesoporous silica SBA-15 as raw material, weigh 0.2g, add it to the ground molten salt system, and continue grinding to make the mesoporous silica SBA-15 uniform Dispersed in molten salt. Put the mixed powder into the corundum crucible and put it into the high temperature zone of the tube furnace. Under normal pressure in the air, the reaction temperature is 450°C, and the holding time is 6 hours. After the reaction, the molten salt is dissolved and removed with deionized water, centrifuged, and dried at 80°C for 4 hours. figure 1 a is the wide-angle X-ray diffraction pattern of the product after heat preservation at 450°C for 6 hours. The result shows that the product remains amorphous without crystallization at 450°C.

Embodiment 2

[0027] Press molten salt NaNO 3 , Accurately weigh 10.0g for grinding, take uncalcined mesoporous silica SBA-15 as raw material, weigh 0.2g, add it to the ground molten salt system, and continue grinding to make the mesoporous silica SBA-15 uniform Dispersed in molten salt. Put the mixed powder into the corundum crucible and put it into the high temperature zone of the tube furnace. Under normal pressure in the air, the reaction temperature is 500°C, and the holding time is 2 hours. After the reaction, the molten salt is dissolved and removed with deionized water, centrifuged, and dried at 80°C for 4 hours. figure 1 b is the wide-angle X-ray diffraction pattern of the product after holding at 500°C for 2 hours. The results show that it has not crystallized into an amorphous structure after holding at 500°C for 2 hours.

Embodiment 3

[0029] Press molten salt NaNO 3 , Accurately weigh 10.0g for grinding, take uncalcined mesoporous silica SBA-15 as raw material, weigh 0.2g, add it to the ground molten salt system, and continue grinding to make the mesoporous silica SBA-15 uniform Dispersed in molten salt. Put the mixed powder into the corundum crucible and put it into the high temperature zone of the tube furnace. Under normal pressure in the air, the reaction temperature is 500°C, and the holding time is 4 hours. After the reaction, the molten salt is dissolved and removed with deionized water, centrifuged, and dried at 80°C for 4 hours. figure 1 c is the wide-angle X-ray diffraction pattern of the product after being kept at 500°C for 4 hours. The results show that crystallization has begun after being kept at 500°C for 4 hours, but the amorphous structure accounts for the majority.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com