Treatment device and method for oil extraction wastewater

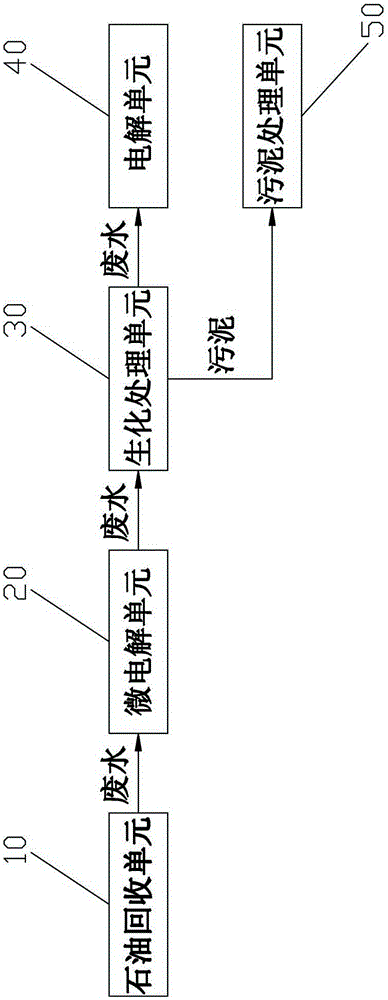

A technology for oil extraction wastewater and treatment device, which is applied in mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., and can solve problems such as large consumption of flocculants and coagulants, difficulties in recycling oil processing, and inability to meet discharge standards. , to achieve the effect of saving the cost of chemicals, reducing the cost of sludge treatment, and reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

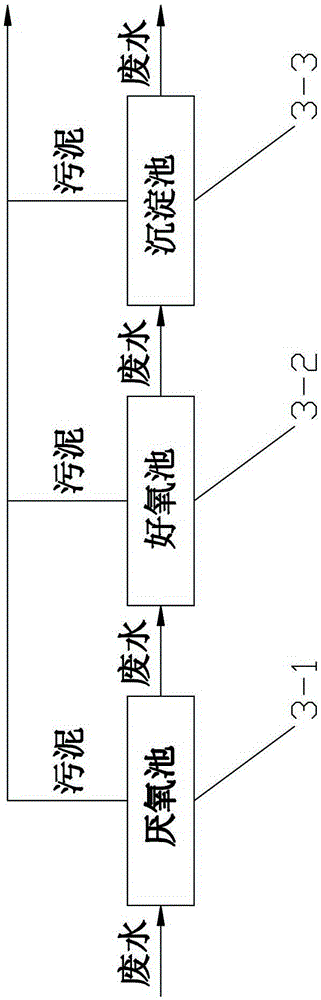

Method used

Image

Examples

Embodiment 1

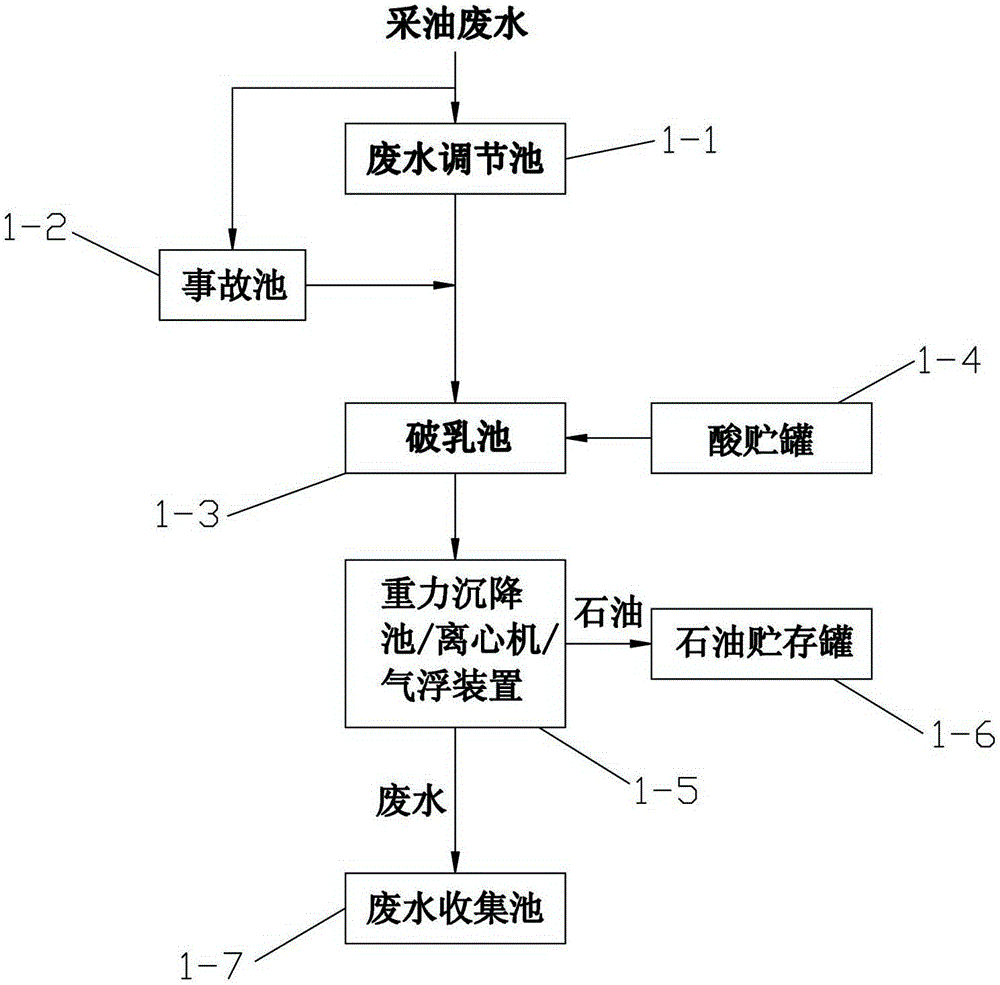

[0063] (1) Demulsification: Collect the oil production wastewater through the pipeline in the wastewater conditioning tank 1-1 and mix it evenly in the wastewater conditioning tank 1-1 to adjust the amount of wastewater. The SS was 50 mg / L, the salt content was 1000 mg / L, and the pH was 6.5. Pump the oil production wastewater that has passed through the wastewater conditioning tank 1 into the demulsification tank 1-3, add sulfuric acid to adjust the pH to 6 for demulsification, and press 5g / m 3 Join PAM.

[0064] (2) Oil recovery: pump the oil production wastewater obtained by demulsification in step (1) into gravity settling tanks 1-5, and recover 49g / m of oil through gravity settling separation and recovery. 3 The oil is stored in oil storage tanks 1-6 and the deoiled oil recovery wastewater is stored in wastewater collection tanks 1-7. The COD of the wastewater is reduced from 300mg / L to 256mg / L.

[0065] In the gravity sedimentation separation, the oil extraction wastewa...

Embodiment 2

[0074] (1) Demulsification: collect the oil production wastewater in the regulating tank 1-1 through the pipeline and mix it evenly in the regulating tank 1-1, adjust the amount of wastewater, and detect that the oil content is 6100mg / L, the COD is 7000mg / L, and the SS is 6100mg / L. 500mg / L, the salt content is 200000mg / L, and the pH is 9.5. Pump the oil production wastewater that has passed through the adjustment tank into the pH adjustment tank (demulsification tank) 1-3, add sulfuric acid to adjust the pH to 2 for demulsification, and press 10g / m 3 Join PAM.

[0075] (2) Petroleum recovery: The oil production wastewater obtained by demulsification in step (1) is separated and recovered by a centrifuge to obtain 5998 g / m of petroleum. 3 And deoiling oil recovery wastewater, oil is stored in storage tanks 1-6, deoiling oil recovery wastewater is stored in wastewater collection tanks 1-7, and the COD of wastewater drops from 7000mg / L to 892mg / L.

[0076] The centrifugal separ...

Embodiment 3

[0085] (1) Demulsification: Collect the oil production wastewater through the pipeline in the wastewater conditioning tank 1-1 and mix it evenly in the wastewater conditioning tank 1-1, adjust the amount of wastewater, and detect that its oil content is 450 mg / L, COD is 610 mg / L, The SS was 200 mg / L, the salt content was 3200 mg / L, and the pH was 7.2. Pump the oil production wastewater that has passed through the wastewater conditioning tank 1 into the demulsification tank 1-3, add hydrochloric acid to adjust the pH to 4 for demulsification, and press 1 g / m 3 Join PAM.

[0086] (2) Oil recovery: The oil extraction wastewater obtained by demulsification in step (1) was separated and recovered by a centrifuge to obtain 448 g / m of oil. 3 And deoiling wastewater, oil is stored in petroleum storage tanks 1-6, and deoiling and oil recovery wastewater is stored in wastewater collection tanks 1-7.

[0087] The centrifugal separation is to pump the oil production wastewater after dem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com