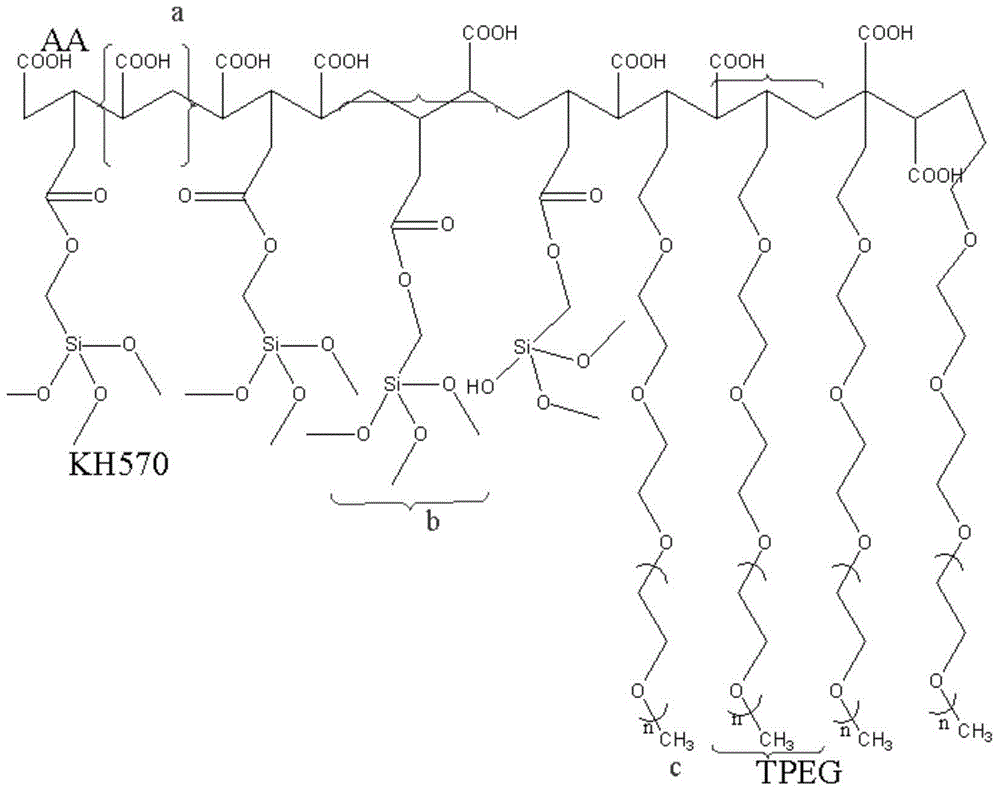

Method of preparing comb block polycarboxylate superplasticizer bonding modified silica fume

A comb-shaped block, polycarboxylic acid technology, applied in the field of cement concrete admixtures, can solve the problems of insignificant increase of steric hindrance effect, insignificant improvement of concrete dispersibility and slump retention, uncontrollable structure, etc. Excellent dispersion retention and stability, improved surface quality, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Synthesize RAFT reagent (comb head)

[0031] (1) Prepare 1000ml of 80 / 20 ethanol / deionized water solution and divide equally into two parts;

[0032] (2) Take 500ml of the above solution in flask 1, and add 91.25g TPEG, 9gAA, 5.6g CTA (4-cyanovaleric acid dithiobenzoic acid), 2.6g initiator (4,4' azobis (4-cyanovaleric acid)), make the concentration of TPEG and AA monomers 19.1wt%, dissolve and stir magnetically;

[0033] (3) Adjust the pH to 8;

[0034] (4)N 2 Deoxygenate for 30 minutes, then place flask 1 in a preheated water bath at 70°C for 12 hours;

[0035] (5) Add excess methanol to flask 1, and the product precipitates for 30 minutes;

[0036] (6) Centrifuge the above product for 5 minutes, then freeze-dry for 1 hour to obtain product 1;

[0037] Step 2: Synthesize copolymer (M-PCE)

[0038] (1) Prepare the ethanol solution of AA and KH570: take 6.3gAA and 9.30gKH570 in 10ml ethanol;

[0039] (2) Take 500ml of 80 / 20 ethanol / deionized water solution into flask 2, and ...

Embodiment 2

[0054] The process methods are the same as in Example 1, and the added amounts of various substances are described in the following table:

[0055] Step 1: Synthesize RAFT reagent (comb head)

[0056] Ethanol / deionized water (80 / 20)

TPEG

AA

CTA

Initiator

1000ml

91.25g

9g

5.6g

2.6g

[0057] Step 2: Synthesize copolymer (M-PCE)

[0058] AA

KH570

CTA

Initiator

5.85g

10.86g

5.6g

2.6g

100ml

[0059] The third step: modified silica fume

[0060] Ethanol

Deionized water

M-PCE

60ml

30ml

5g

11g

[0061] The product obtained is denoted as P2.

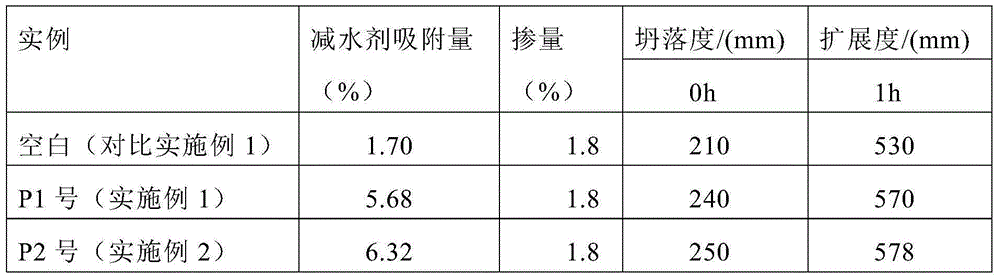

[0062] The slump, expansion and compressive strength of concrete are all carried out in accordance with the relevant operations in GB8076-2008 and GB50081-2002.

[0063] The silica fume prepared in the examples was used in the production of commercial concrete. The preparation method was as follows: the raw material ratio was:

[0064] Cement: fly ash: silica fume: water: sand: crushed stone: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com