Polymer film modified by fluororesin and preparation method thereof

A polymer film and polymer technology, applied in the direction of coating, can solve the problems of poor adhesion, achieve the effect of improving barrier performance, easy industrialized large-area processing, and retaining physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

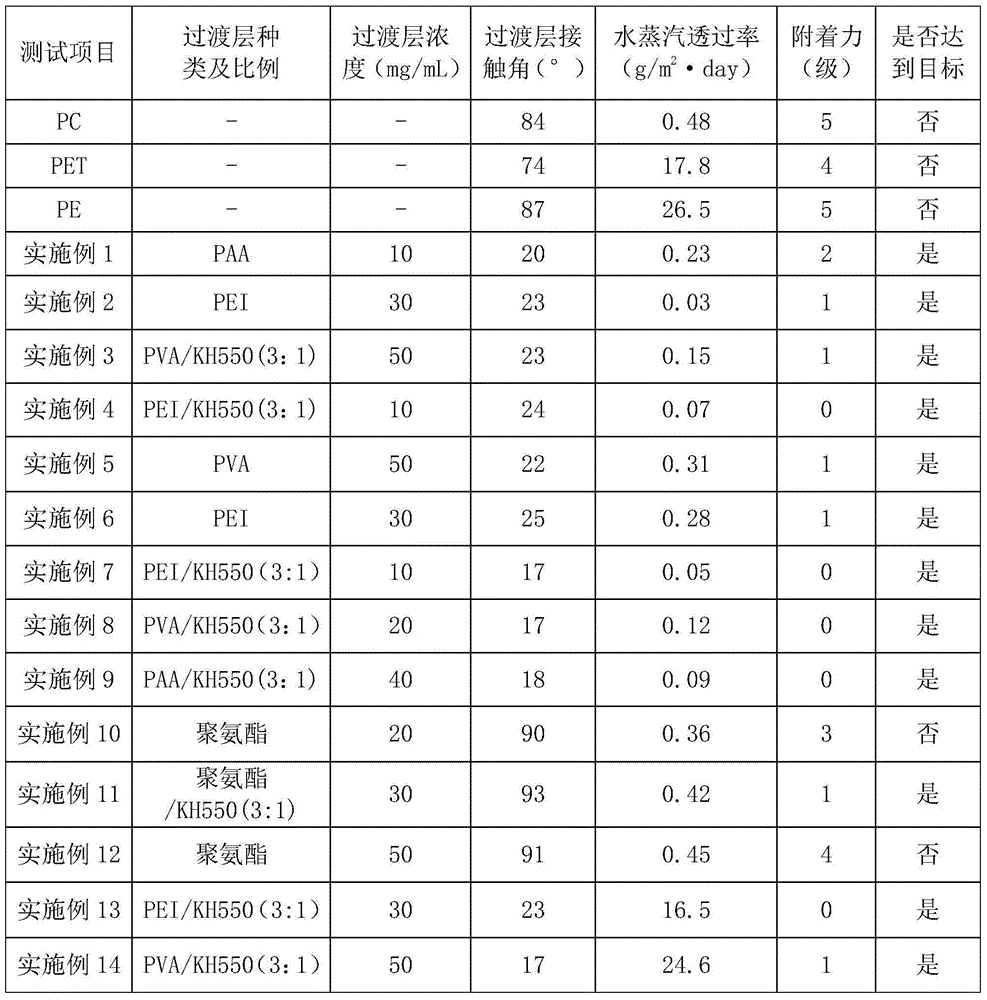

Examples

Embodiment 1

[0034] The polychlorinated p-xylylene film (thickness 100μm) was treated with air plasma (100V, 2min), so that the surface was activated and modified. The film was placed in a PAA solution (10mg / mL) and dip-coated for 1min. Pre-dry in an oven at 80°C for 3 minutes for use; then dip-coat the pre-dried sample in a pre-prepared fluororesin solution (50 mg / mL) for 1 minute, and then cure it in an oven at 80°C for 1 hour to obtain a certain Flat polymer film surface for barrier to moisture vapor and adhesion.

Embodiment 2

[0036] The polychlorinated p-xylylene film (thickness 100 μm) was ultrasonically cleaned in acetone and ethanol for 10 min and 15 min in turn, and dried with nitrogen. Treat the clean polymer film with air plasma (150V, 1.5min) to activate and modify the surface. The film is sprayed with PEI solution (30mg / mL) for 1min and then placed in an oven at 75°C for 5min for pre-drying. Then put the pre-dried sample in the pre-prepared fluororesin solution (40mg / mL) for dip coating for 1min, and then cure it in an oven at 80°C for 1h to obtain a flat polymer film surface with a certain barrier to water vapor and adhesion .

Embodiment 3

[0038] Put the polychlorinated p-xylylene film (thickness 100 μm) into a container containing acetone and ethanol for ultrasonic cleaning for 15 min, and dry it with nitrogen. Treat the clean polymer film with air plasma (200V, 1min) to activate the modified film on the surface and place it in a container containing a mixed solution (50mg / mL) of PVA and KH550 (ratio: 3:1) Dip coating for 2 minutes, put it in an oven at 80°C for 5 minutes and pre-dry it for use; then spray the pre-dried sample with a pre-prepared fluororesin solution (30mg / mL) for 1 minute, and then cure it in an oven at 80°C for 1 hour to obtain Flat polymer film surface with certain water vapor barrier and adhesion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com