Phosphorus-nitrogen co-reactive flame retardant used for polyurethane, preparation method therefor and application thereof

A synergistic reaction and flame retardant technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as harsh and complicated synthesis conditions, and achieve low cost and high yield , Improve the effect of low flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

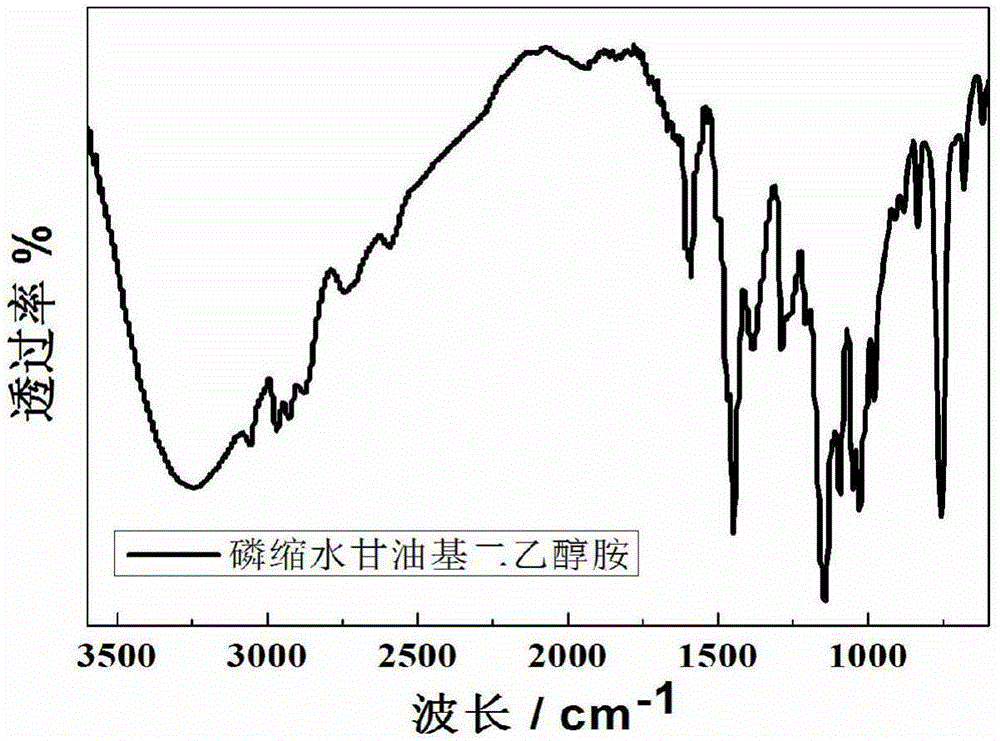

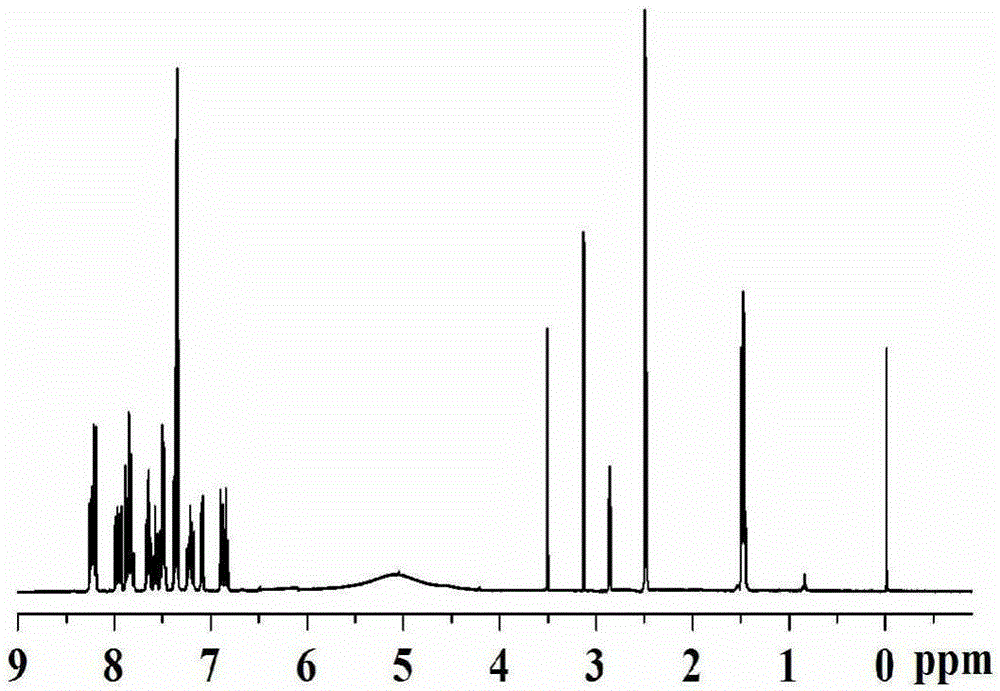

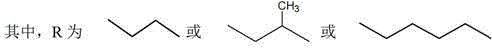

[0044] Add 105g (1.0mol) diethanolamine and 110mL absolute ethanol to a dry three-necked flask, raise the temperature to 28°C, add 92.5g (1.0mol) epichlorohydrin dropwise while stirring, react for 5 hours, and raise the temperature to 50°C, NaOH solution (concentration: 50wt%) was added dropwise at a constant speed, and the reaction was continued for 2 h to obtain a white suspension. Remove NaCl by filtration, remove the solvent by rotary evaporation, and dry to obtain the reaction intermediate glycidyldiethanolamine.

[0045] Add 80.5g (0.5mol) of glycidyldiethanolamine and 200mL of absolute ethanol to a dry three-necked flask, raise the temperature to 120°C, add 108g (0.5mol) of DOPO in batches while stirring, and react for 8 hours. A light yellow transparent liquid was obtained. Add diethyl ether to the liquid, a white precipitate is formed, remove the filtrate by filtration, rinse the precipitate with diethyl ether several times, and dry at 80°C to obtain a white powder, ...

Embodiment 2

[0048] Add 133g (1.0mol) of diisopropanolamine and 150mL of absolute ethanol into a dry three-necked flask, raise the temperature to 25°C, add 92.5g (1.0mol) of epichlorohydrin dropwise while stirring, react for 5 hours, and raise the temperature to At 40°C, NaOH solution (concentration: 50wt%) was added dropwise at a constant speed, and the reaction was continued for 2 hours to obtain a white suspension. Remove NaCl by filtration, remove the solvent by rotary evaporation, and dry to obtain the reaction intermediate glycidyl diisopropanolamine.

[0049] Add 94.5g (0.5mol) glycidyl diisopropanolamine and 200mL absolute ethanol to a dry three-necked flask, raise the temperature to 120°C, add 108g (0.5mol) DOPO in batches while stirring, and react for 8 hours to obtain shallow Yellow transparent liquid. Add diethyl ether to the liquid, a white precipitate is formed, remove the filtrate by filtration, rinse the precipitate with diethyl ether several times, and dry at 80°C to obta...

Embodiment 3

[0052] Add 161g (1.0mol) of dibutanolamine and 200mL of absolute ethanol into a dry three-necked flask, raise the temperature to 30°C, add 92.5g (1.0mol) of epichlorohydrin dropwise while stirring, react for 5 hours, and raise the temperature to 60°C ℃, NaOH solution (concentration 50%) was added dropwise at a constant speed, and the reaction was continued for 2 hours to obtain a white suspension. Remove NaCl by filtration, remove the solvent by rotary evaporation, and dry to obtain the reaction intermediate glycidyl butanolamine.

[0053] Add 108.5g (0.5mol) glycidyl butanolamine and 100mL absolute ethanol to a dry three-necked flask, raise the temperature to 120°C, add 108g (0.5mol) DOPO in batches while stirring, and react for 8 hours to obtain light yellow transparent liquid. Add diethyl ether to the liquid, a white precipitate is formed, remove the filtrate by filtration, wash the precipitate with diethyl ether several times, and dry at 80°C to obtain a white powder, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com