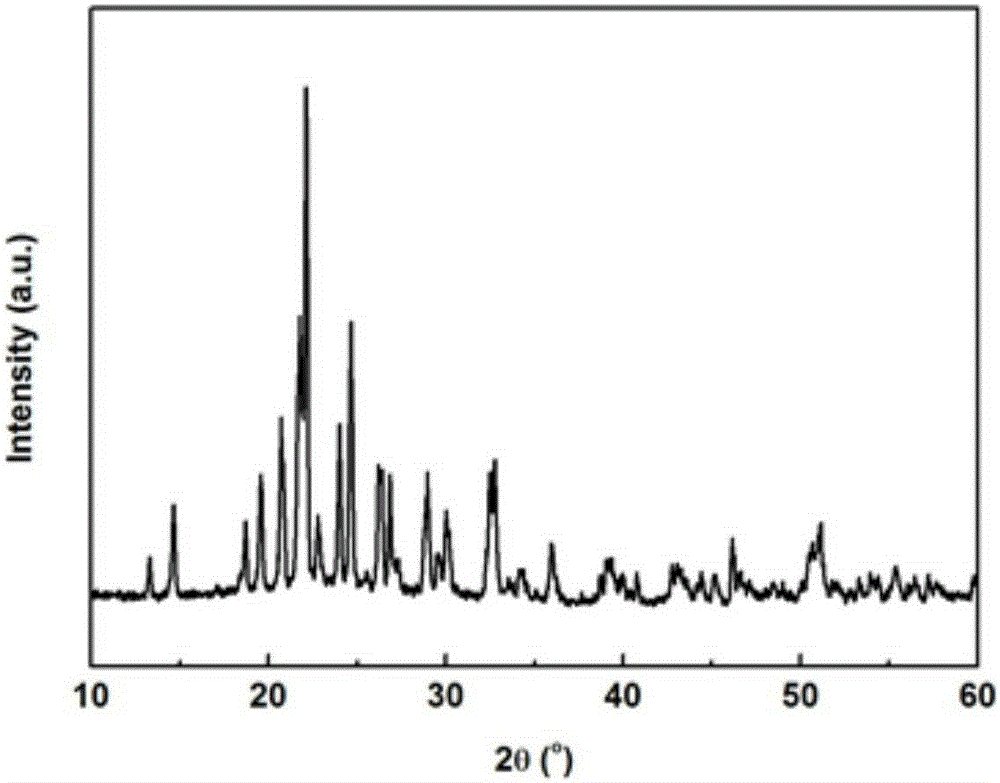

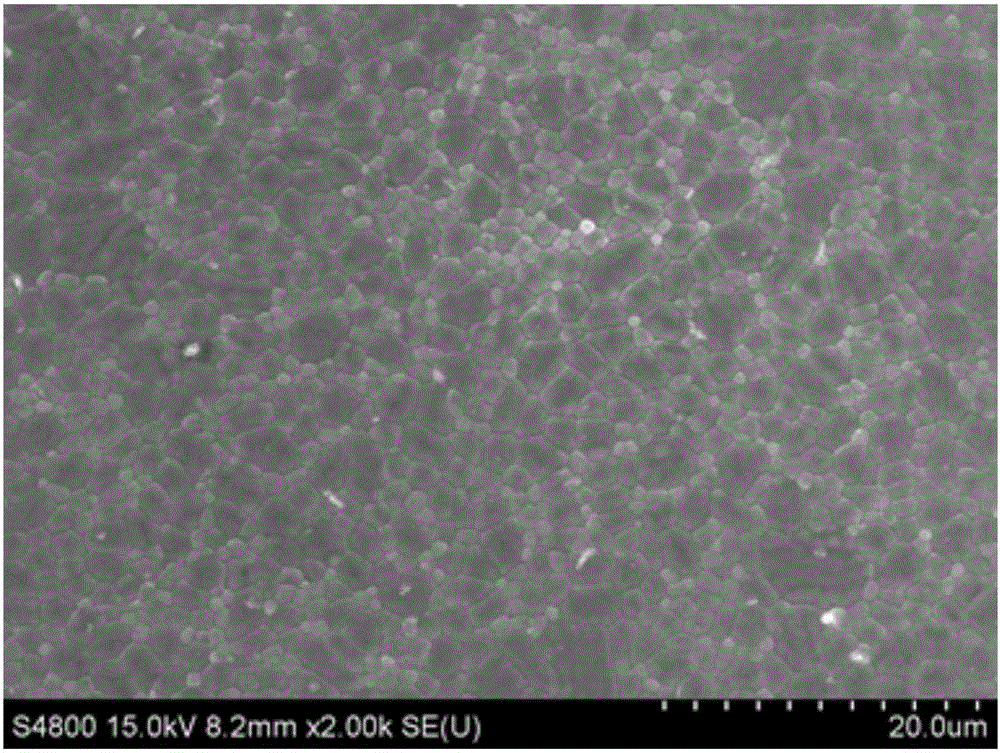

Method for preparing negative thermal expansion material Sc2Mo3O12 film

A negative thermal expansion material, sc2mo3o12 technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of phase change negative thermal expansion response temperature range, high heat treatment temperature, difficult practical application, etc. The effect of wide thermal expansion response temperature range, low heat treatment temperature, stable and good negative thermal expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

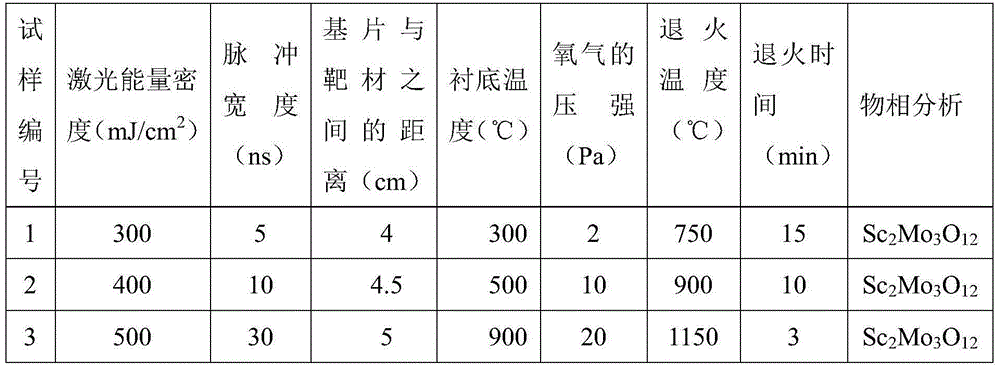

Embodiment 1

[0022] 1. Target preparation:

[0023] to Sc 2 o 3 and MoO 3 As the raw material, weigh the mixed materials according to the molar ratio of 1:3, place them in alcohol for ball milling for 12 minutes, dry the raw materials in a 60°C oven after ball milling, grind them with an agate mortar for 0.5h, and then add the precursor The total mass of 3% polyvinyl alcohol is ground to make it evenly mixed, then cold-pressed at 50MPa, degummed at 500°C for 0.5h, sintered at 750°C for 6h, and cooled in the furnace to obtain Sc 2 Mo 3 o 12 ceramic target;

[0024] 2. The quartz substrate is cleaned and activated by conventional processes;

[0025] Put the quartz substrate in H 2 SO 4 :H 2 o 2 :H 2 Ultrasonic cleaning in the solution of O=1:1:2 for 5 minutes, pour off the acid solution, clean with deionized water, and ultrasonically clean with acetone for 5 minutes, and then immerse the cleaned quartz substrate in absolute ethanol solution for use , before sending the substrate ...

Embodiment 2

[0031] 1. Target preparation:

[0032] to Sc 2 o 3 and MoO 3 As the raw material, weigh the mixed materials according to the molar ratio of 1:3, place them in alcohol for ball milling for 18 hours, dry the raw materials in an oven at 80°C after ball milling, grind for 0.7 hours with an agate mortar, and then add the precursor The total mass of 4% polyvinyl alcohol is ground to make it evenly mixed, then cold-pressed at 100MPa, debinding at 500°C for 0.7h, sintered at 900°C for 12h, and cooled in the furnace to obtain Sc 2 Mo 3 o 12 ceramic target;

[0033] 2. The quartz substrate is cleaned and activated by conventional processes;

[0034] Put the quartz substrate in H 2 SO 4 :H 2 o 2 :H 2 Ultrasonic cleaning in the solution of O=1:1:2 for 5 minutes, pour off the acid solution, clean with deionized water, and ultrasonically clean with acetone for 5 minutes, and then immerse the cleaned quartz substrate in absolute ethanol solution for use , before sending the subst...

Embodiment 3

[0040] 1. Target preparation:

[0041] to Sc 2 o 3 and MoO 3 As the raw material, weigh the mixed materials according to the molar ratio of 1:3, put them into the ball mill in alcohol for 24 hours, dry the raw materials in a 100°C oven after ball milling, grind them with an agate mortar for 1 hour, and then add 5% polyvinyl alcohol by mass, grind to mix evenly, then cold press molding at 150MPa, debinding at 500°C for 1h, sintering at 1150°C for 24h, and get Sc after cooling in the furnace 2 Mo 3 o 12 ceramic target;

[0042] 2. The quartz substrate is cleaned and activated by conventional processes;

[0043] Put the quartz substrate in H 2 SO 4 :H 2 o 2 :H 2 Ultrasonic cleaning in the solution of O=1:1:2 for 5 minutes, pour off the acid solution, clean with deionized water, and ultrasonically clean with acetone for 5 minutes, and then immerse the cleaned quartz substrate in absolute ethanol solution for use , before sending the substrate into vacuum, dry the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com