Surface covered tin‑nano tio 2 Membrane electronic device housing and method for processing the same

A surface covering and electronic device technology is applied to the electronic device casing and its processing field covered with a TiN-nano TiO2 film. The effect of reducing the growth or spread of bacteria and improving the competitiveness of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

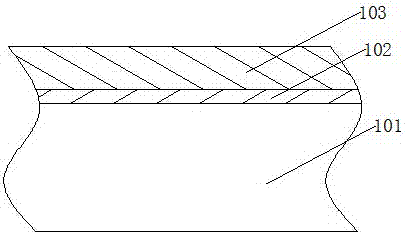

[0038] Surface covered with TiN-nano TiO 2 Film electronic device housing, such as figure 2 As shown, including the substrate and the nano TiO covering the outer surface of the substrate 2 Membrane 103 and connection matrix with nano TiO 2 The pre-layer of the film 103; the nano TiO 2 The film 103 is a rutile phase lattice structure or an anatase phase lattice structure or a mixed lattice structure of rutile phase and anatase phase, and its thickness is 20-80 nm; the substrate is a ceramic substrate 101, and the pre-layer is TiN The preset layer 102.

[0039] The surface provided by the invention is covered with TiN-nano TiO 2 The electronic device housing of the membrane does not interfere with electronic signals, and has the characteristics of easy cleaning and self-cleaning. Nano TiO 2 The film 103 can not only make the housing present a metallic appearance, but can also decompose dust, sweat or residual organic pollutants adhered to the surface of the housing under the irrad...

Embodiment 2

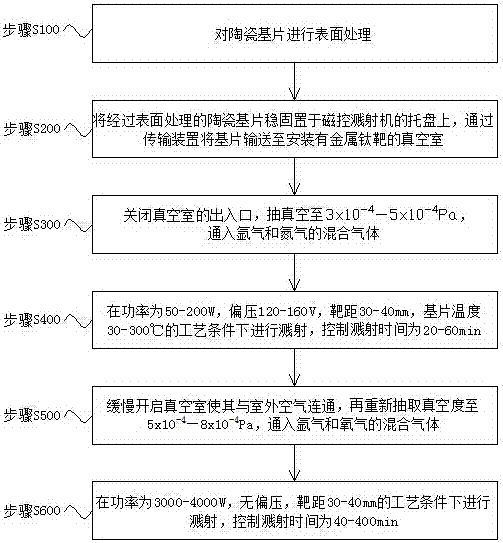

[0043] Surface covered with TiN-nano TiO 2 The processing method of the electronic device housing of the film, such as figure 1 As shown, including the following steps:

[0044] Step S100: performing surface treatment on the ceramic substrate 101;

[0045] Step S200: Place the surface-treated ceramic substrate 101 firmly on the tray of the magnetron sputtering machine, and transport the substrate to the vacuum chamber where the metal titanium target is installed through the transmission device;

[0046] Step S300: Close the entrance and exit of the vacuum chamber, and pump the vacuum to 3x10 -4 —5x10 -4 Pa, a mixed gas of argon and nitrogen;

[0047] Step S400: Sputtering is performed under the process conditions of a power of 50-200W, a bias voltage of 120-160V, a target distance of 30-40mm, and a substrate temperature of 30-300°C, and the sputtering time is controlled to be 20-60min;

[0048] Step S500: Slowly open the vacuum chamber to communicate with the outdoor air, and then re-ex...

Embodiment 3

[0052] This embodiment is further optimized on the basis of Embodiment 2. Further, the step S100 specifically refers to the following process:

[0053] Step S110: Put the ceramic substrate 101 in a water area with a water temperature of 60-80°C and let stand for 1-2 hours;

[0054] Step S120: Put the ceramic substrate 101 into a cleaning tank equipped with a 20-50% acetone solution, and use ultrasonic cleaning for 10-20 minutes;

[0055] Step S130: Rinse the ceramic substrate 101 with flowing deionized water to remove the acetone solution;

[0056] Step S140: Take out the ceramic substrate 101 and blow dry its surface with cold air, and set it aside. The other parts of this embodiment are the same as that of Embodiment 2, so they will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com