Photocatalytic organic waste gas treatment system

A technology of organic waste gas and treatment system, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., to achieve the effects of convenient maintenance, reduced use cost and improved treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

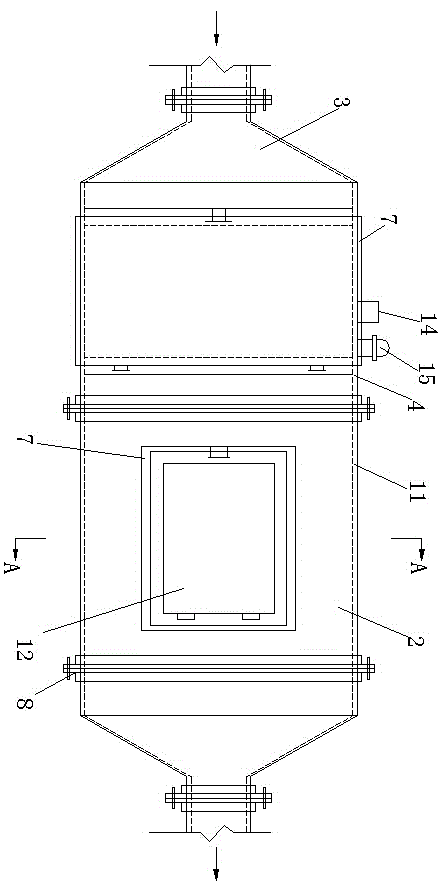

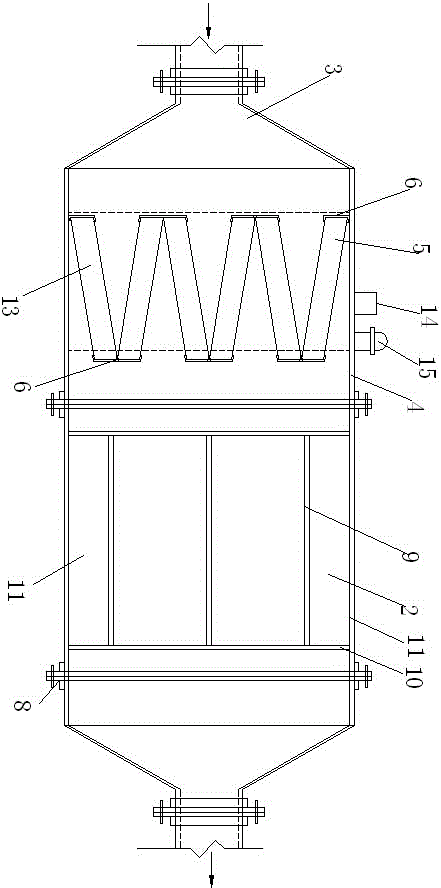

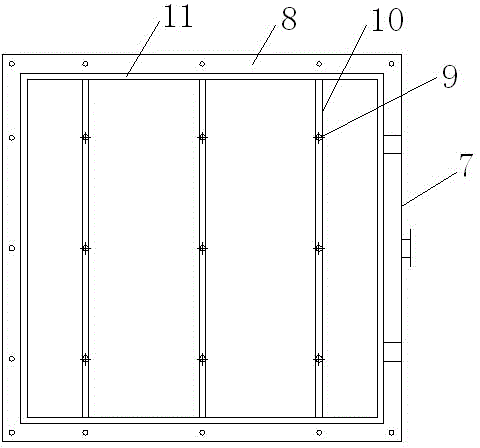

[0024] exist figure 1 , 2 , In the first embodiment shown in 3, a photocatalytic organic waste gas treatment system consists of a pre-filter component (1), a pre-filter component alarm control system, a photocatalytic treatment component (2), a photocatalytic treatment component control system , Composed of ventilation ducts. The pre-filter component is composed of an expansion expansion section (3), a cubic housing (4), an activated carbon fiber filter plate (5), a slot (6), a warranty door (7), and a flange (8); The above-mentioned photocatalytic treatment component (2) consists of a housing (4) and flanges (8) at both ends, an ultraviolet lamp (9), a lamp installation frame (10), a titanium dioxide coating (11), and an observation window (12) consists of a warranty door (7), the ultraviolet lamp tube (9) is installed in the housing (4), the interval between the ultraviolet lamp tubes (9) is consistent with the interval between the housing (4), and the ultraviolet lamp Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com