Process for incinerating household garbage by use of steelmaking convertor

A domestic waste and steelmaking converter technology, which is applied to the improvement of process efficiency, incinerator, combustion method, etc., can solve the problems of inapplicability, etc., and achieve the effect of complete incineration, high energy utilization rate and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

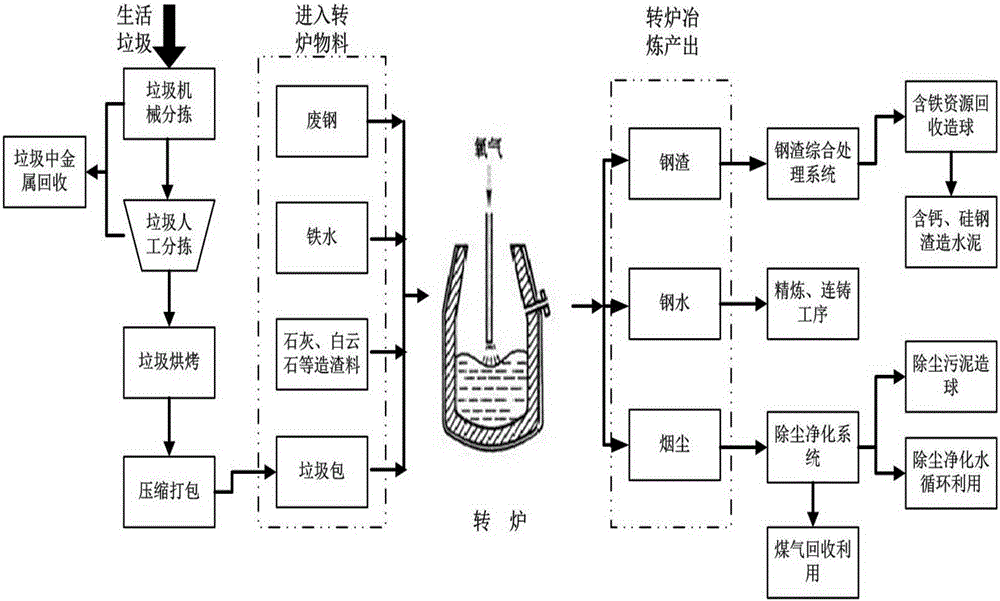

[0029] figure 1 Shown is the technological process that utilizes steelmaking converter to incinerate domestic waste of the present invention, will refer to below figure 1 Exemplary embodiments of the present invention are described.

[0030] The domestic waste treatment process flow of the present invention includes: establishing waste sorting, baking and packaging facilities, and classifying the domestic waste to be treated. The waste sorting can be separated by mechanical and manual methods to separate metal waste and avoid copper, aluminum, etc. , gold and other metals enter the steelmaking converter to pollute the molten steel.

[0031] After sorting, other garbage (including waste paper, fiber, kitchen waste, etc.) is baked through the waste heat steam baking device of the converter to remove the moisture of the garbage to ≤8%. The moisture content of the garbage entering the furnace will directly affect the quality of the garbage. As for the treatment effect, if the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com