A kind of beneficiation and purification method of microcrystalline graphite

A technology of microcrystalline graphite and purification method, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of not meeting the dissociation particle size requirements of microcrystalline graphite embedded with microcrystalline particles, and increasing the acid consumption. Environmental protection impact , Restricting industrial application and other issues, to achieve the effect of simplifying the multi-stage wet grinding-flotation process, eliminating the investment in mineral processing equipment, and reducing the number of grinding times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

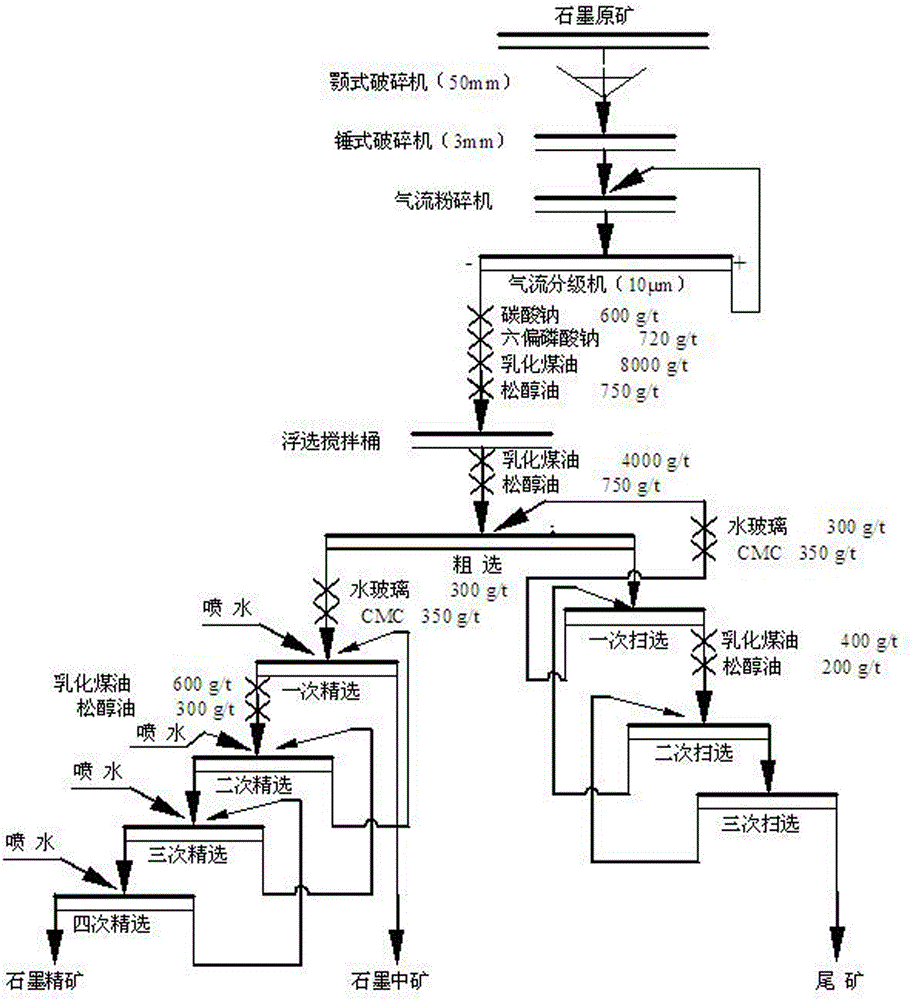

[0030] refer to figure 2 The shown process flow diagram illustrates the embodiment 1 of the present invention, and the beneficiation and purification method of the microcrystalline graphite of the present embodiment is carried out according to the following steps:

[0031] (1) The microcrystalline graphite raw ore with a fixed carbon content of 65~70% is crushed to below 50mm by a jaw crusher. After crushing, the microcrystalline graphite below 50mm is crushed to below 3mm by a hammer crusher. After pulverization, the microcrystalline graphite powder with a particle size of -10μm and +10μm is obtained by air classifier classification, and the microcrystalline graphite powder with a particle size of +10μm is returned to the original ultrafine pulverizing equipment to be pulverized and classified again until the particle size is -10μm, Enter the flotation step, control the amount of ultra-fine pulverization and the ultra-fine pulverization time, so that the weight of each retur...

Embodiment 2

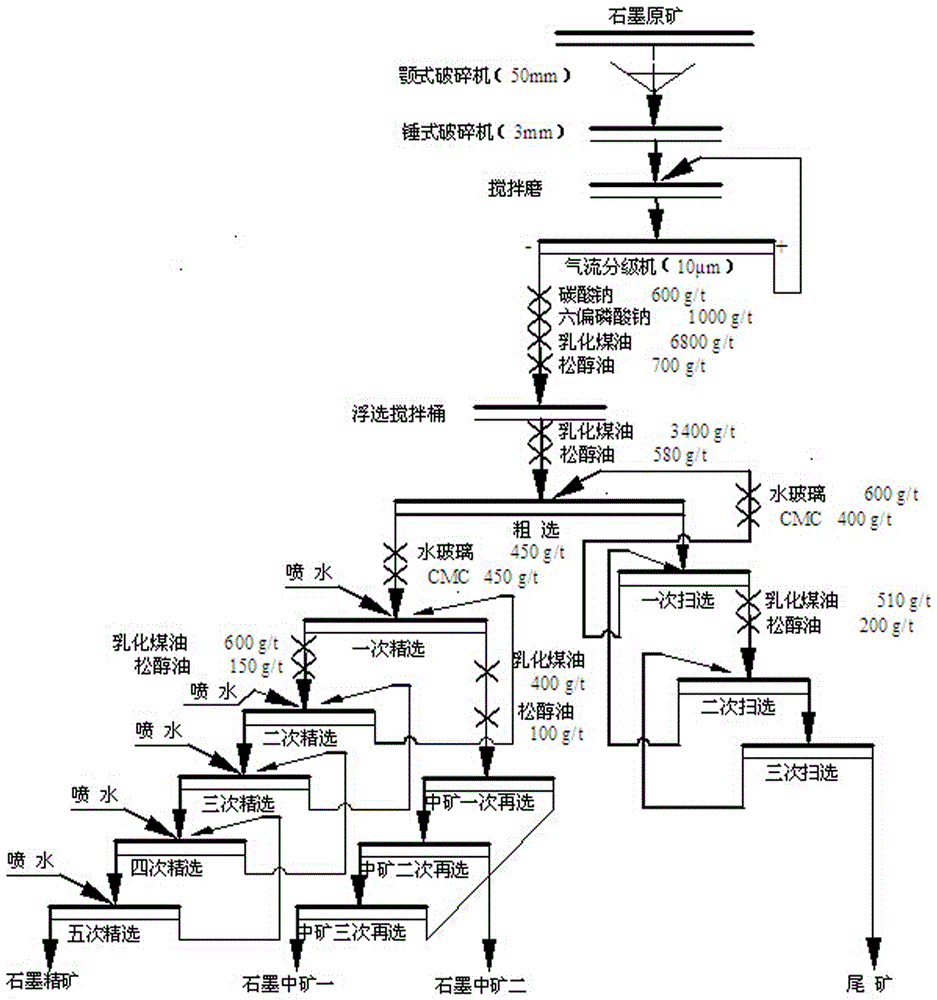

[0039] refer to image 3 The shown process flow diagram illustrates the embodiment 2 of the present invention, and the beneficiation and purification method of the microcrystalline graphite of the present embodiment is carried out according to the following steps:

[0040] (1) The microcrystalline graphite raw ore with a fixed carbon content of 50~60% is crushed to below 50mm by a jaw crusher. After crushing, the microcrystalline graphite below 50mm is crushed to below 3mm by a hammer crusher. After pulverization, the microcrystalline graphite powder with a particle size of -10μm and +10μm is obtained by air classifier classification, and the microcrystalline graphite powder with a particle size of +10μm is returned to the original ultrafine pulverizing equipment to be pulverized and classified again until the particle size is -10μm, Enter the flotation step, control the amount of ultra-fine pulverization and the ultra-fine pulverization time, so that the weight of each return...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com