Microbial fermentation organic fertilizer and preparation method thereof

A microbial fermentation and organic fertilizer technology, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve environmental pollution and other problems, and achieve the effects of increasing crop yields, eliminating drug residues, and completely harmless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

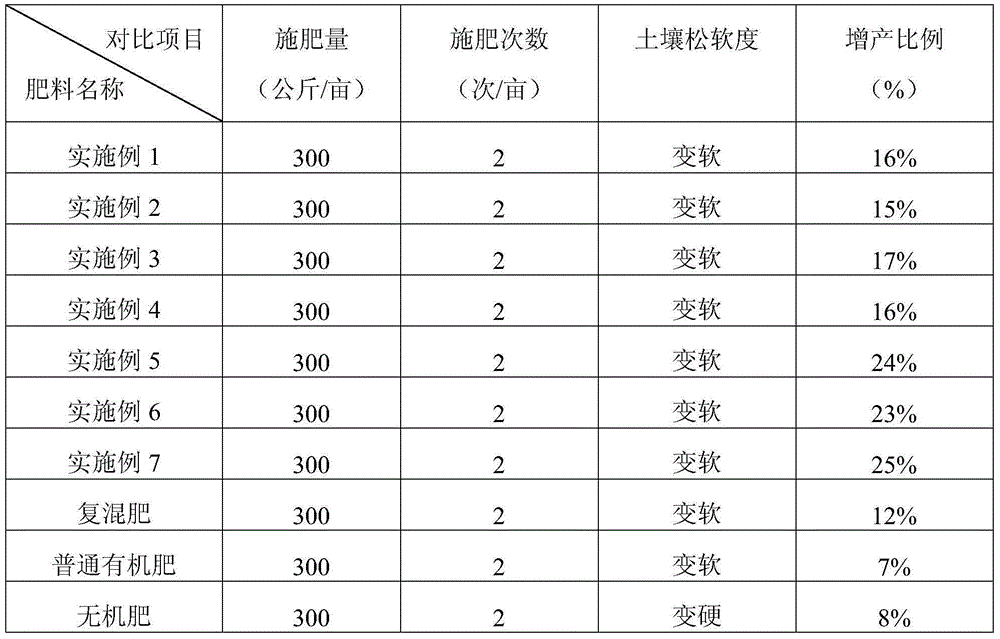

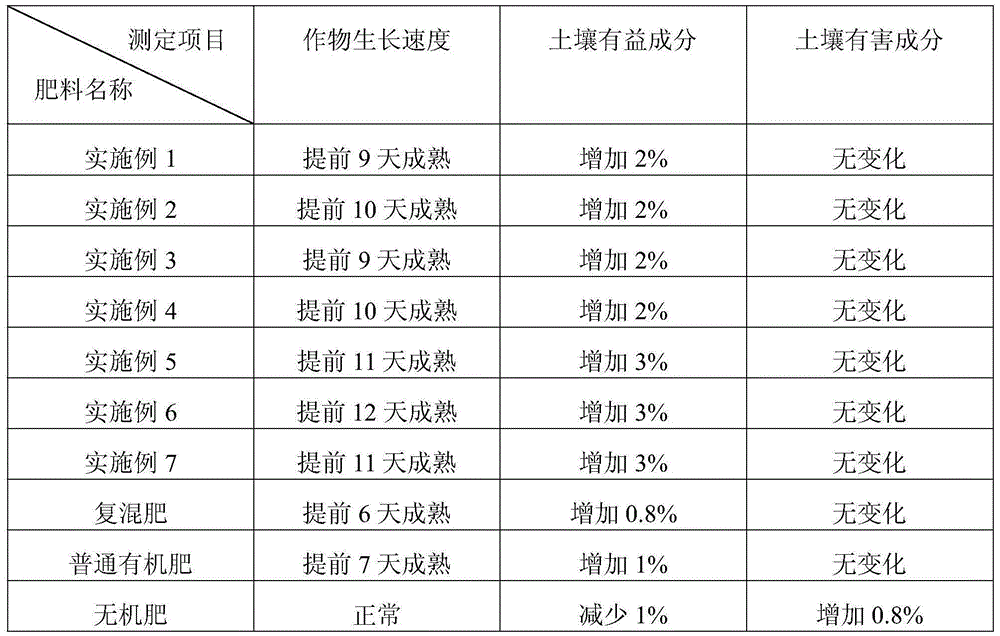

Examples

Embodiment 1

[0034] A preparation method for microbial fermented organic fertilizer, comprising the following steps:

[0035] Step 1. Take the stomach content, intestinal content and animal feces of the slaughtered cattle and sheep with a weight ratio of 2:1:1, add them to a drum sieve with an aperture of 30mm, separate and screen them, and then transfer them to a drum-type high-temperature furnace and heat them to 180 °C, rotate at a speed of 6 rpm and keep warm for 2 hours, and dry the stomach contents, intestinal contents and animal feces until the moisture content is 55%;

[0036] Step 2, adding the dried stomach content, intestinal content and animal feces into a high-temperature fermentation tank, and performing aerobic fermentation at 80°C for 2 hours to obtain an aerobic fermentation product;

[0037] Step 3, transfer the aerobic fermentation product to the fermentation workshop, and add 1L of multifunctional microbial inoculant per ton of aerobic fermentation product, then mix eve...

Embodiment 2

[0048] A preparation method for microbial fermented organic fertilizer, comprising the following steps:

[0049] Step 1. Take the stomach content, intestinal content and animal feces of the slaughtered cattle and sheep with a weight ratio of 3:2:1, add them to a drum sieve with an aperture of 40mm, separate and screen them, and then transfer them to a drum-type high-temperature furnace to heat to 160 °C, rotate at a speed of 8 rpm and keep warm for 3 hours, and dry the stomach content, intestinal content and animal manure until the moisture content is 60%;

[0050] Step 2, adding the dried stomach content, intestinal content and animal feces into a high-temperature fermentation tank, and performing aerobic fermentation at 90°C for 4 hours to obtain an aerobic fermentation product;

[0051] Step 3, the aerobic fermentation product is sent to the fermentation workshop, and 5L of multifunctional microbial inoculant is added to the aerobic fermentation product per ton, then mixed ...

Embodiment 3

[0062] A preparation method for microbial fermented organic fertilizer, comprising the following steps:

[0063] Step 1. Take the stomach content, intestinal content and animal manure of the slaughtered cattle and sheep with a weight ratio of 2:2:1, add them to a drum sieve with an aperture of 50mm, separate and screen them, and then transfer them to a drum-type high-temperature furnace and heat them to 190 °C, rotate at a speed of 9 rpm and keep warm for 2 hours, dry the stomach contents, intestinal contents and animal feces until the moisture content is 55%;

[0064] Step 2, adding the dried stomach content, intestinal content and animal feces into a high-temperature fermentation tank, and performing aerobic fermentation at 80° C. for 3 hours to obtain an aerobic fermentation product;

[0065] Step 3, the aerobic fermentation product is sent to the fermentation workshop, and 8L of multifunctional microbial inoculant is added to the aerobic fermentation product per ton, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com