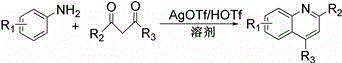

Method for synthesizing quinoline by aromatic amine and diketone

A technology of aromatic amines and derivatives, which is applied in the field of synthesis of quinoline derivatives, can solve the problems of complex reaction steps, poor reaction effect, strong substrate restriction, etc., and achieves easy separation and purification, simple operation steps and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The synthetic method of 2-methyl-4-phenylquinoline is as follows: in reaction vessel, add aniline 0.5mmol (46.5mg), 1-phenyl-1,3-butanedione 0.5mmol (81mg), catalyst AgOTf0. 005mmol (1.29mg) and HOTf0.01mmol (1.5mg), toluene 2mL. React in an oil bath at 120°C for 24 hours, cool to room temperature, add water to quench the reaction, wash three times with ethyl acetate, separate the layers, combine the organic layers, decolorize with activated carbon, filter, dry over anhydrous sodium sulfate, concentrate under reduced pressure, and the product passes through Purified by column chromatography, the eluent was petroleum ether:ethyl acetate=10:1 (v / v), and a white solid product was obtained with a yield of 82% and a purity of 99.8%. 1 HNMR (400MHz, CDCl 3 ) δ ppm: 8.75 (d, J =7.6Hz, 1H), 7.88-8.23(m, 6H), 7.61(m, 3H), 3.04(s, 3H); 13 CNMR (400MHz, CDCl 3 ) δ ppm: 157.9, 154.2, 135.1, 133.5, 130.1, 130.0, 129.9, 129.8, 129.1, 127.1, 124.7, 122.3, 121.6, 20.4; HRMS (EI) ...

Embodiment 2

[0030] 2, the synthetic method of 8-dimethyl-4-phenylquinoline is as follows: in reaction vessel, add o-methylaniline 0.5mmol (53.5mg), 1-phenyl-1, 3-butanedione 0.5mmol ( 81mg), catalyst AgOTf0.005mmol (1.29mg) and HOTf0.01mmol (1.5mg), toluene 2mL. React in an oil bath at 120°C for 24 hours, cool to room temperature, add water to quench the reaction, wash three times with ethyl acetate, separate the layers, combine the organic layers, decolorize with activated carbon, filter, dry over anhydrous sodium sulfate, concentrate under reduced pressure, and the product passes through Purified by column chromatography, the eluent was petroleum ether:ethyl acetate=10:1 (v / v), and a white solid product was obtained with a yield of 78% and a purity of 99.7%. 1 HNMR (400MHz, CDCl 3 ) δ ppm: 8.23 (d, J =8.0Hz, 2H), 7.79(d, J =8.4Hz, 1H), 7.69(s, 1H), 7.36-7.54(m, 5H), 2.89(s, 3H), 2.69(s, 3H); 13 CNMR (400MHz, CDCl 3 ) δ ppm: 155.1, 147.1, 144.8, 140.0, 138.2, 129.5, 129.2, 128.8...

Embodiment 3

[0032] 2, the synthetic method of 7-dimethyl-4-phenylquinoline is as follows: in reaction vessel, add m-methylaniline 0.5mmol (53.5mg), 1-phenyl-1, 3-butanedione 0.5mmol ( 81mg), catalyst AgOTf0.005mmol (1.29mg) and HOTf0.01mmol (1.5mg), toluene 2mL. React in an oil bath at 120°C for 24 hours, cool to room temperature, add water to quench the reaction, wash three times with ethyl acetate, separate the layers, combine the organic layers, decolorize with activated carbon, filter, dry over anhydrous sodium sulfate, concentrate under reduced pressure, and the product passes through Purified by column chromatography, the eluent was petroleum ether: ethyl acetate = 10:1 (v / v), to obtain a white solid product with a yield of 84% and a purity of 99.9%. 1 HNMR (400MHz, CDCl 3 ) δ ppm: 8.53 (d, J =7.6Hz, 1H), 8.06(m, 3H), 7.69(s, 1H), 7.59-7.68(m, 4H), 2.99(s, 3H), 2.65(s, 3H); 3 CNMR (400MHz, CDCl 3 ) δ ppm: 157.5, 153.5, 147.3, 138.4, 133.3, 132.0, 130.03, 129.96, 128.9, 125.3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com