Low-noise lubricating grease and preparation method thereof

A lubricating grease and low-noise technology, which is applied in the field of low-noise lubricating grease and its preparation, can solve the problems of easy loss of low-noise lubricating grease, high production cost, and poor noise reduction effect, and achieve low production cost, improved service life, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

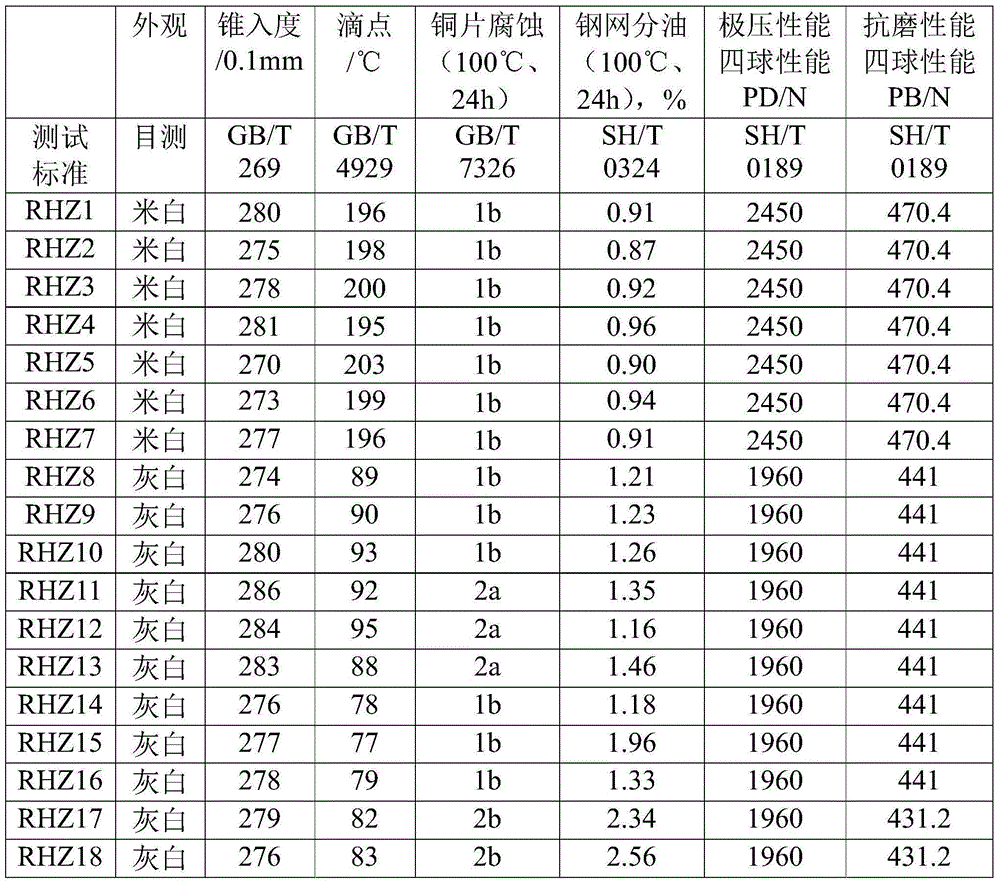

Examples

Embodiment 1

[0021] This embodiment provides a low-noise lubricating grease suitable for micro-motors and a preparation method of the low-noise lubricating grease. The preparation method sequentially includes the steps of material preparation, lye preparation, reaction, high-temperature refining and modulation, specifically as follows:

[0022] (1) material preparation

[0023] Weigh 770g base oil (615g mineral oil, 155g synthetic oil), 130g thickener (75g stearic acid, 25g lauryl hydroxystearic acid, 30g synthetic fatty acid), 70g alkali (lithium hydroxide), 10g rust inhibitor (3g barium petroleum sulfonate, 1g calcium petroleum sulfonate, 6g rust inhibitor T743), 10g antioxidant (5g diphenylamine, 5g2,6-di-tert-butyl p-cresol), 10g structure improver (2g polymethyl Methyl acrylate, 3g ethylene propylene copolymer, 1g natural rubber, 4g polyisobutylene), spare.

[0024] (2) lye making

[0025] Dissolve alkali in water below 80°C to form lye for later use;

[0026] (3) Reaction

[002...

Embodiment 2

[0034] This embodiment provides a low-noise lubricating grease suitable for micro-motors and a preparation method of the low-noise lubricating grease. The preparation method sequentially includes the steps of material preparation, lye preparation, reaction, high-temperature refining and preparation. In this example, only the raw materials used to prepare grease are different from those in Example 1, and the steps of making lye, reaction steps, high-temperature refining steps and preparation steps are completely consistent with those in Example 1. The raw materials used to prepare grease are as follows:

[0035] Weigh 770g base oil (600g mineral oil, 170g synthetic oil), 130g thickener (50g lauryl hydroxystearic acid, 30g oleic acid, 25g palmitic acid, 25g synthetic fatty acid), 70g alkali (sodium hydroxide), 10g Rust inhibitor (3, g barium petroleum sulfonate, 1g calcium petroleum sulfonate, 1g zinc petroleum sulfonate, 2g rust inhibitor T746, 3g zinc naphthenate), 10g antiox...

Embodiment 3

[0038] This embodiment provides a low-noise lubricating grease suitable for micro-motors and a preparation method of the low-noise lubricating grease. The preparation method sequentially includes the steps of material preparation, lye preparation, reaction, high-temperature refining and preparation. In this example, only the raw materials used to prepare grease are different from those in Example 1, and the steps of making lye, reaction steps, high-temperature refining steps and preparation steps are completely consistent with those in Example 1. The raw materials used to prepare grease are as follows:

[0039] Weigh 770g base oil (700g mineral oil, 70g synthetic oil), 130g thickener (70g oleic acid, 15g palmitic acid, 45g synthetic fatty acid), 70g alkali (potassium hydroxide), 10g rust inhibitor (4g petroleum sulfonic acid Barium, 6g rust inhibitor T746), 10g antioxidant (6g2,6-di-tert-butyl p-cresol, 4g phenyl-α-naphthylamine), 10g structure improver (3g ethylene propylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com