Indirect Chain Straw Hot Air Stove

A technology of hot blast stove and chain row, which is applied to heating devices, air heaters, fluid heaters, etc., can solve the problems of large energy loss, insufficient heat exchange, and low degree of automation of flue heat pipes, and achieves easy maintenance and overall integration. The effect of compact structure and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

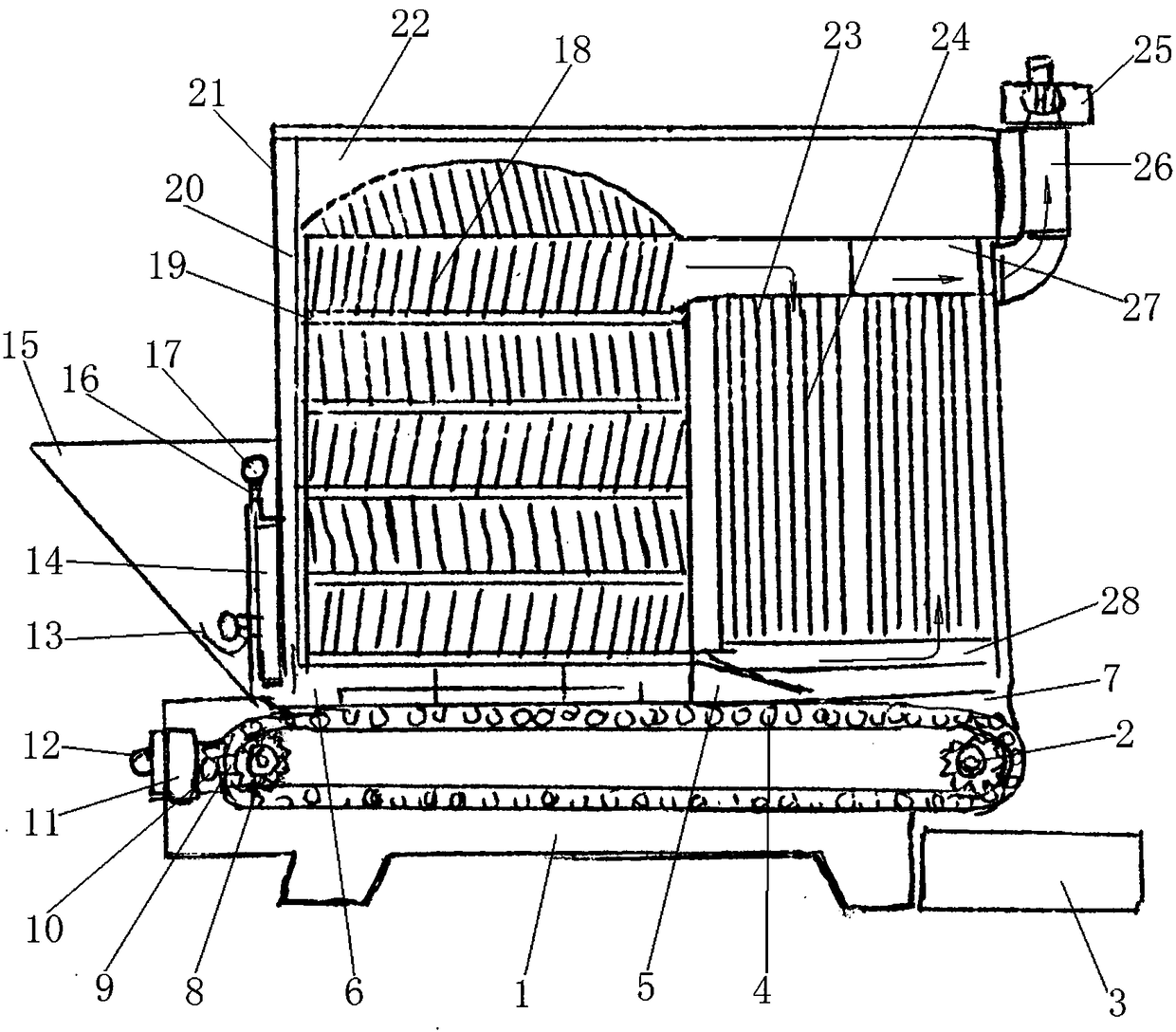

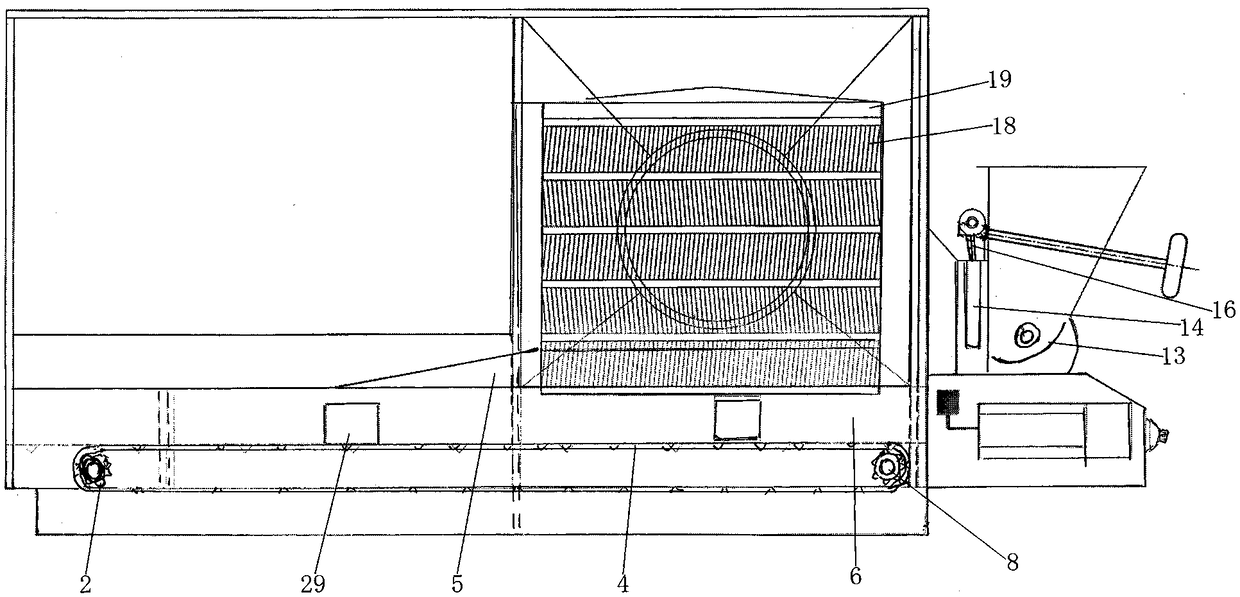

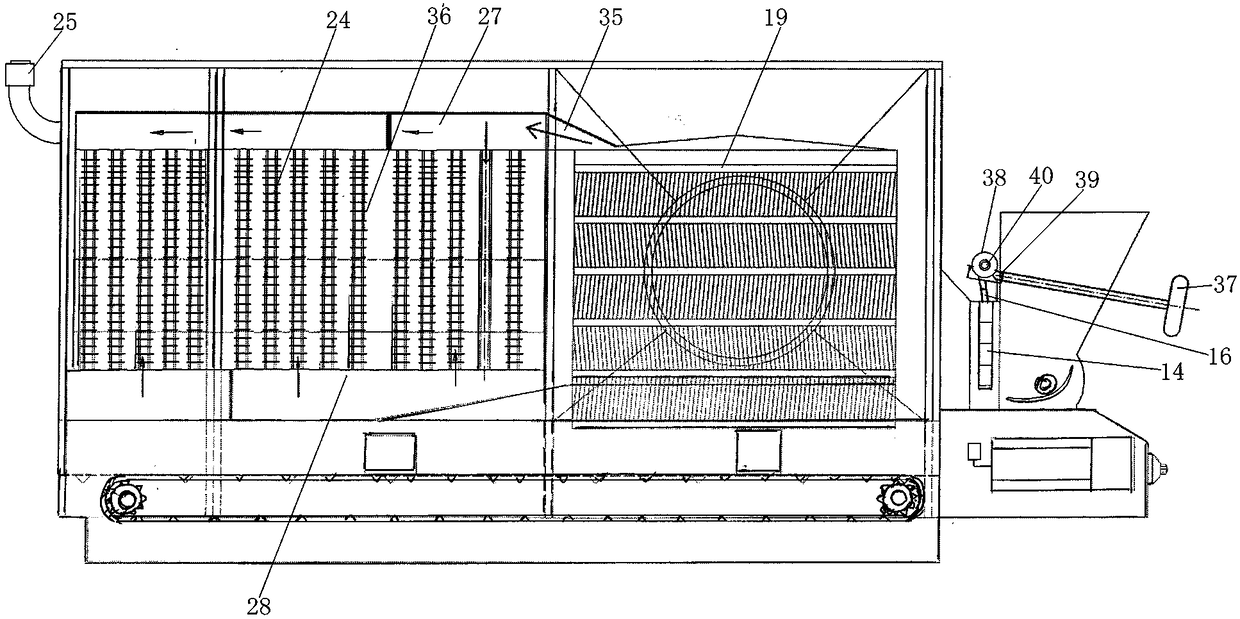

[0037] Refer to attached Figure 1~6 The indirect chain row straw hot blast stove consists of a furnace body, a heat dissipation fin type furnace device, a spiral heat dissipation fin type heat pipe group device, a feed adjustment and backfire prevention device, an automatic chain row device, a blower 30, an induced draft fan 34, Flue fan 25 forms.

[0038] The furnace body includes a heat exchange chamber 22, a frame 21, a base 1, a furnace door 31, a blast air inlet adjustment handle, an air damper 29, a heat insulation sealing plate 20, an air inlet 33, and an air inlet mesh plate 32. A frame 21 is connected to the top of the base 1 .

[0039] The heat dissipation fin type furnace device includes a furnace chamber 19, heat dissipation fins 18, feed passage 6, auxiliary combustion passage 5, and flue gas transition passage 35. Furnace hearth 19 is installed on the front portion of base 1, and the diameter of fire hearth 19 can be between 1.2~2m depending on the size of fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com