Multifunctional nanomaterials with metal-organic framework mesoporous structure and preparation method

A technology of metal-organic framework and mesoporous structure, which is applied in the field of preparation of nanocomposite materials, can solve the problems of differential thermal stability and chemical stability, and achieve high stability, easy production and promotion, and simple and easy preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

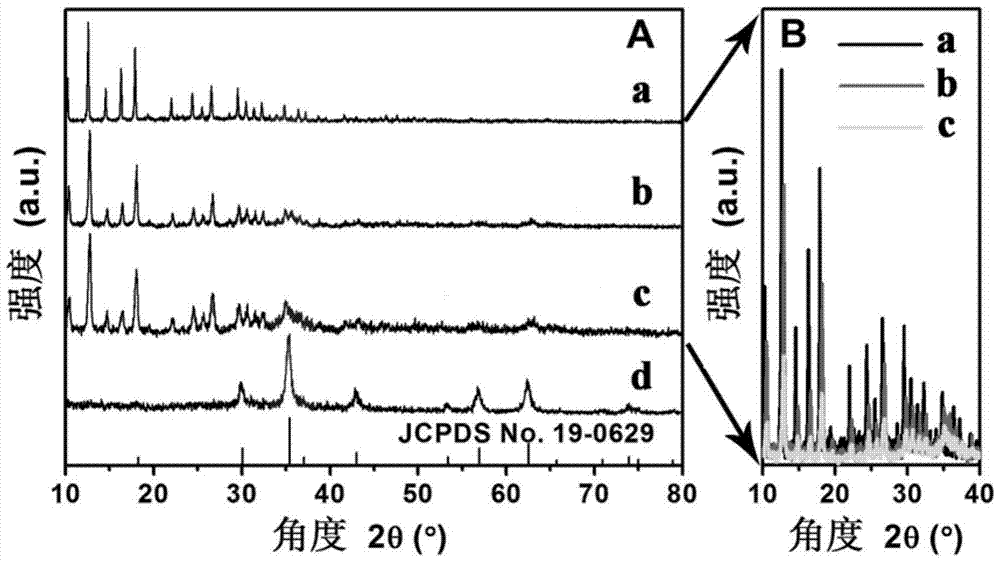

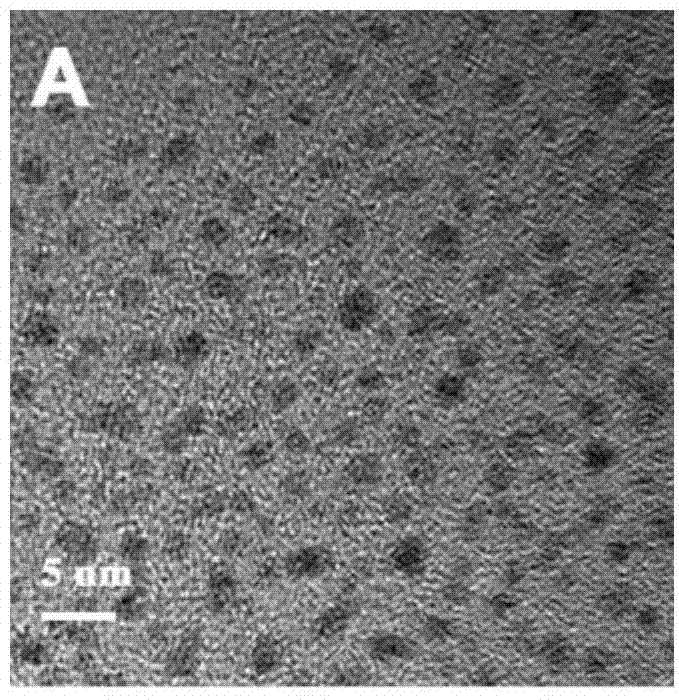

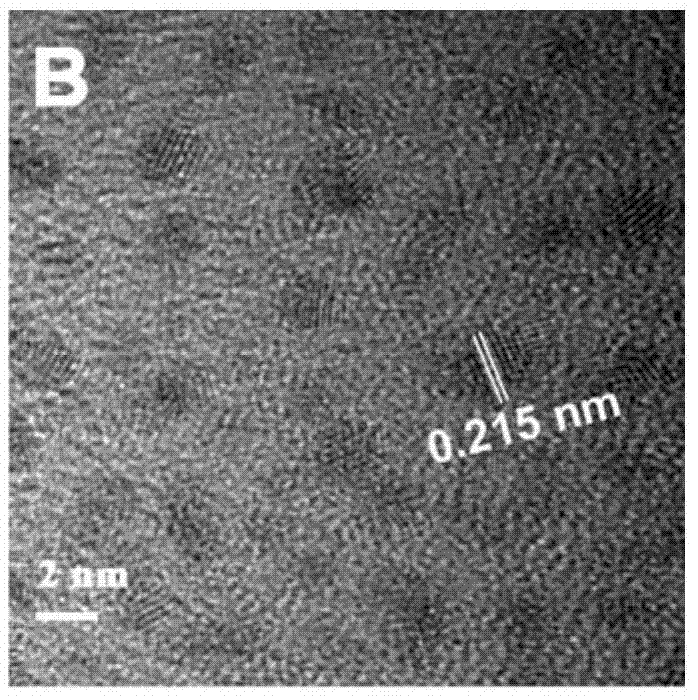

[0022] (1) Synthesis of monodisperse magnetic colloid clusters by high temperature pyrolysis process. The specific scheme is as follows: First, the key NaOH / DEG stock solution in the synthesis process, 2.5mmol / mL NaOH is dissolved in 8mL diethylene glycol (DEG), the solution is heated to 120°C and maintained for 1h under stirring, then cooled to 70°C stand-by. Then 0.576g polyacrylic acid (PAA) and 1.08g FeCl 3 After dissolving in 30mL DEG to form a transparent solution, heat to 220°C with stirring in the presence of nitrogen, when the color of the mixture in the flask turns light yellow, quickly inject 2mL NaOH / DEG mixed solution into it under stirring , kept at 220°C for 2h and then cooled to room temperature. The final product was washed three times with distilled water and absolute ethanol, and finally dispersed into 10 mL of deionized water to obtain magnetic colloid clusters with a diameter of about 10 nm.

[0023] (2) The reaction of aqueous solution at room temperat...

Embodiment ( 2

[0026] (1) Synthesis of monodisperse magnetic colloid clusters by high temperature pyrolysis process. The specific scheme is as follows: Firstly, the key NaOH / DEG stock solution in the synthesis process, 2.5mmol / mL NaOH is dissolved in 6mL diethylene glycol (DEG), the solution is heated to 120°C and maintained under stirring for 1h, then cooled to 70°C stand-by. Then 0.5g polyacrylic acid (PAA) and 0.9g FeCl 3 After dissolving in 28mL DEG to form a transparent solution, heat to 220°C with stirring in the presence of nitrogen. When the color of the mixture in the flask turns light yellow, quickly inject 2.5mL NaOH / DEG mixed solution into it under stirring , kept at 220°C for 2h and then cooled to room temperature. The final product was washed three times with distilled water and absolute ethanol, and finally dispersed into 10 mL of deionized water to obtain magnetic colloid clusters with a diameter of about 30 nm.

[0027] (2) The reaction of aqueous solution at room tempera...

Embodiment ( 3

[0030] (1) Synthesis of monodisperse magnetic colloid clusters by high temperature pyrolysis process. The specific scheme is as follows: First, the key NaOH / DEG stock solution in the synthesis process, 2.5mmol / mL NaOH is dissolved in 10mL diethylene glycol (DEG), the solution is heated to 120°C and maintained under stirring for 1h, then cooled to 70°C stand-by. Then 0.6g polyacrylic acid (PAA) and 1.5g FeCl 3 After dissolving in 34mL DEG to form a transparent solution, heat to 220°C with stirring in the presence of nitrogen, when the color of the mixture in the flask turns light yellow, quickly inject 3.5mL NaOH / DEG mixed solution into it under stirring , kept at 220°C for 2h and then cooled to room temperature. The final product was washed three times with distilled water and absolute ethanol, and finally dispersed into 10 mL of deionized water to obtain magnetic colloidal clusters with a particle size of about 70 nm.

[0031] (2) The reaction of aqueous solution at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com