Vanadium-free rare-earth-based titanium-tungsten powder and preparation method therefor

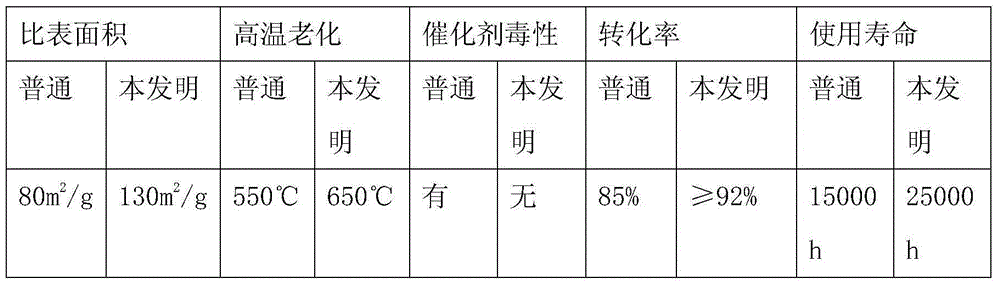

A rare earth-based, titanium-tungsten powder technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Improve dispersion, chemical poisoning of catalysts, etc., to achieve the effect of inhibiting catalyst poisoning, short production cycle, and improving sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, a vanadium-free rare earth-based titanium-tungsten powder, the composition includes: titanium dioxide 750kg, ammonium metatungstate 10kg, cerium nitrate 15kg, lanthanum nitrate 15kg, rhenium nitrate 10kg, manganese molybdenum nickel composite metal oxide (Mn-Mo- Ni-OX) 10kg, monoethanolamine 5kg, citric acid 5kg.

[0025] Wherein, the molar ratio of Mn / Mo / Ni elements in the Mn-Mo-Ni-Ox composite metal oxide active component is 1:0.5:0.5. Titanium dioxide is anatase nano titanium dioxide

[0026] The preparation method is:

[0027] (1) Anatase-type nano-titanium dioxide is added a sufficient amount of water to be made into a suspension with a concentration of 15%;

[0028] (2) Add 20 liters of water into the dissolving tank, then add monoethanolamine into the dissolving tank, when the temperature reaches 90°C, add ammonium metatungstate and stir evenly, and dissolve it completely for later use;

[0029] (3) Add 50 liters of water into the dissolving tank...

Embodiment 2

[0033] Embodiment 2, a kind of vanadium-free rare earth base titanium tungsten powder, composition comprises: titanium dioxide 900kg, ammonium paratungstate 60kg, cerium sulfate 20kg, lanthanum sulfate 40kg, manganese molybdenum nickel composite metal oxide (Mn-Mo-Ni-O X ) 15kg, monoethanolamine 15kg, citric acid 25kg.

[0034] Among them, manganese molybdenum nickel composite metal oxide (Mn-Mo-Ni-O X ) in the Mn / Mo / Ni element molar ratio of 1:1:1. Titanium dioxide is anatase nano titanium dioxide.

[0035] The preparation method is:

[0036] (1) Anatase-type nano-titanium dioxide is added a sufficient amount of water to be made into a suspension with a concentration of 15%;

[0037] (2) Add 30 liters of water into the dissolving tank, and then add monoethanolamine into the dissolving tank to mix and dissolve. When the temperature reaches 100°C, add ammonium paratungstate and stir evenly, and dissolve it completely for later use;

[0038] (3) 60 liters of water are added to...

Embodiment 3

[0042] Embodiment 3, a kind of vanadium-free rare earth base titanium tungsten powder, composition comprises: titanium dioxide 800kg, ammonium metatungstate 50kg, rhenium nitrate 50kg, manganese molybdenum nickel composite metal oxide (Mn-Mo-Ni-O X ) 12kg, monoethanolamine 10kg, citric acid 20kg.

[0043] Among them, manganese molybdenum nickel composite metal oxide (Mn-Mo-Ni-O X ) in Mn / Mo / Ni element molar ratio is 1:0.8:0.8. Titanium dioxide is anatase nano titanium dioxide.

[0044] The preparation method is:

[0045] (1) Anatase-type nano-titanium dioxide is added a sufficient amount of water to be made into a suspension with a concentration of 15%;

[0046] (2) Add 20 liters of water into the dissolving tank, and then add monoethanolamine into the dissolving tank to mix and dissolve. When the temperature reaches 88°C, add ammonium metatungstate and stir evenly, and dissolve it completely for later use;

[0047] (3) 50 liters of water are added to the dissolving tank, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com