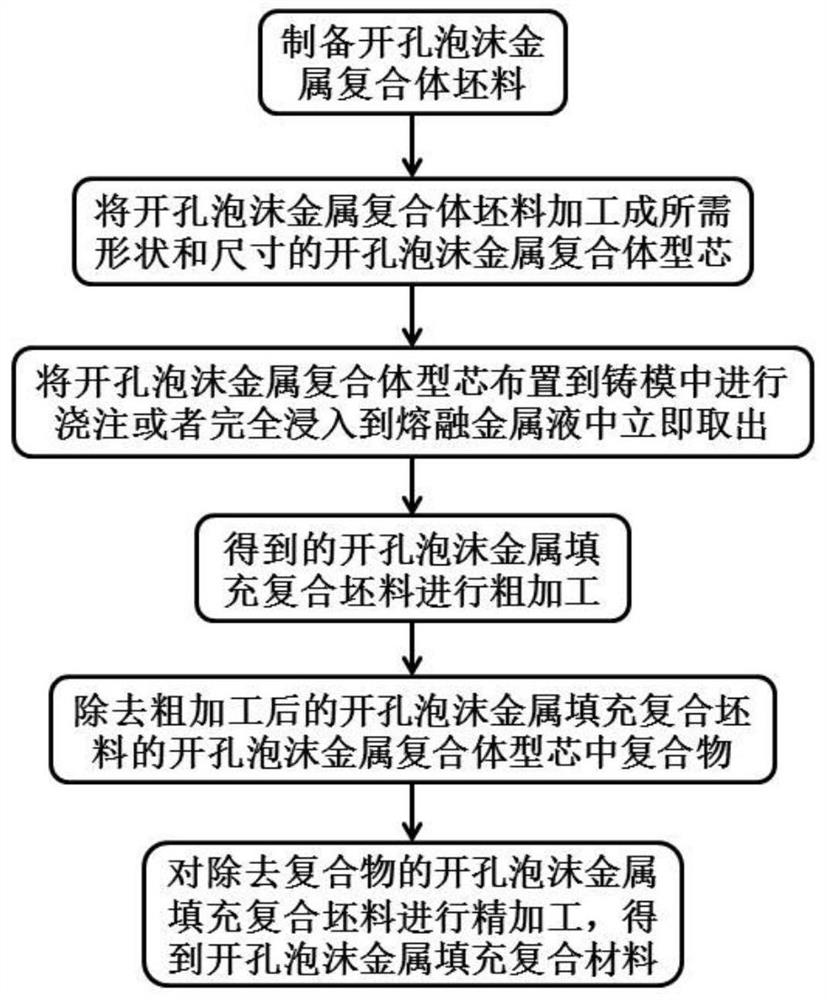

Manufacturing method of open-cell foam metal filled composite material

A technology of open-cell foam and composite materials, which is applied in the field of preparation of layered composite materials, can solve the problems of aging open-cell foam metal sandwich panels such as porosity and thickness, uncontrollability, and high temperature resistance, and achieve low production costs, Improved yield and high temperature aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

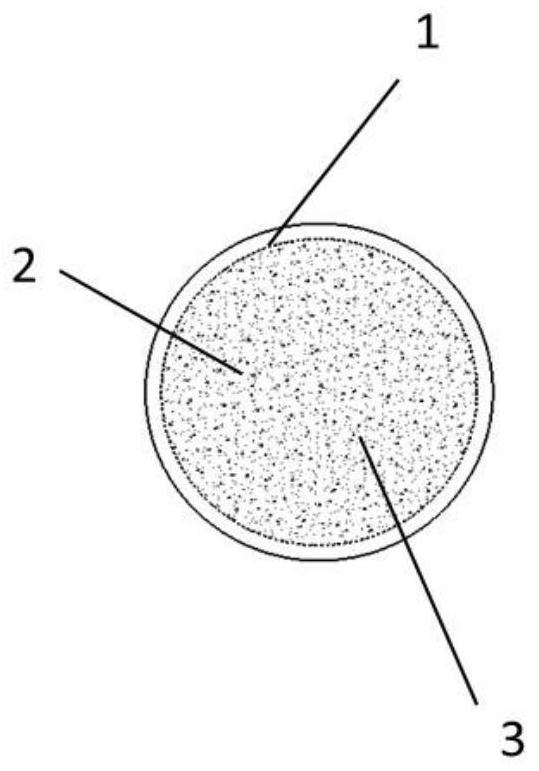

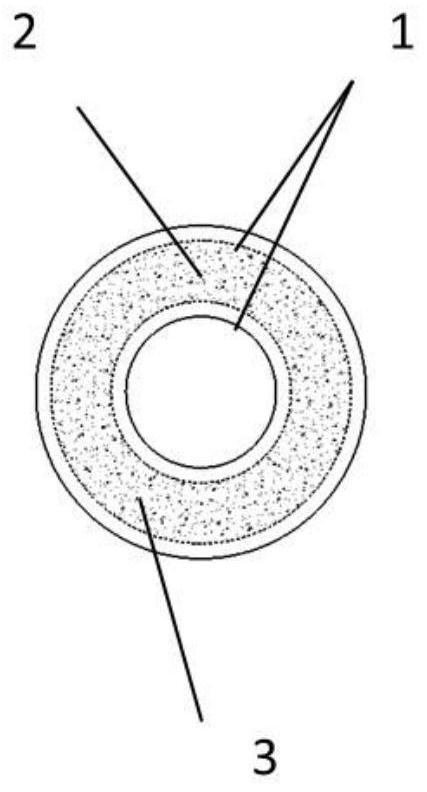

[0046] Embodiment 1: The die-casting process method of the foamed copper filling tube that is fully filled with the unsalted presolvation treatment open-cell foamed copper as the core

[0047] The specific implementation steps are as follows:

[0048] S1. Prepare an open-cell copper foam blank with required porosity and pore size for the fully filled copper foam filling tube. First, select high temperature resistant and water-soluble salt particles through the porosity and pore size, arrange them in the metal cavity and Compacting, and then pouring the molten metal liquid of metal copper, the required filling material of the fully filled copper foam filling pipe, for percolation casting, without salt precipitating treatment after cooling, and finally obtaining an open-cell foam copper billet without salt precipitating treatment.

[0049] S2. Carry out wire cutting on the unsalted presolventized open-cell foam copper billet selected in step S1 on a wire cutting machine, and obt...

Embodiment 2

[0054] Embodiment 2: take the open-cell foam copper-aluminum composite body as the core to make the die-casting process of the foam copper filling tube that fills completely

[0055] S1, prepare the open-cell copper foam blank of the required porosity and pore size of the foamed copper filling pipe of all filling, select the open-cell foam copper blank of required porosity and pore size as open-cell metal foam, because open-cell metal foam and The composite metals belong to different metals, and the melting point of the open-cell foam metal is higher than that of the composite metal. Metal aluminum is selected as the composite metal, so that the composite metal aluminum can be removed according to the melting point difference in subsequent operations. First, select the open-cell foamed copper billet with the required porosity and pore size, then pour the molten metal of the molten composite metal aluminum, pressurize so that the metal liquid of the molten composite metal alumin...

Embodiment 3

[0061] Embodiment 3: The hot-dipping process method of making fully filled foamed copper filled pipes with unsalted presolvation-treated open-cell foamed copper as the base material

[0062] S1. Prepare an open-cell copper foam blank with required porosity and pore size for the fully filled copper foam filling tube. First, select high temperature resistant and water-soluble salt particles through the porosity and pore size, arrange them in the metal cavity and Compacting, and then pouring the molten metal liquid of metal copper, the required filling material of the fully filled copper foam filling pipe, for percolation casting, without salt precipitating treatment after cooling, and finally obtaining an open-cell foam copper billet without salt precipitating treatment.

[0063] S2. Carry out wire cutting on the unsalted presolvation treatment open-cell foam copper billet selected in step S1 on a wire cutting machine, and obtain the unsalt presolution treatment open cell of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com