Method for compositely welding aluminum alloy in TIG welding manner and MIG welding manner alternately

A composite welding and aluminum alloy technology, which is applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of poor weld formation, complicated welding equipment, and low welding efficiency, and achieve the reduction of tungsten electrodes Burning loss, automatic welding, and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

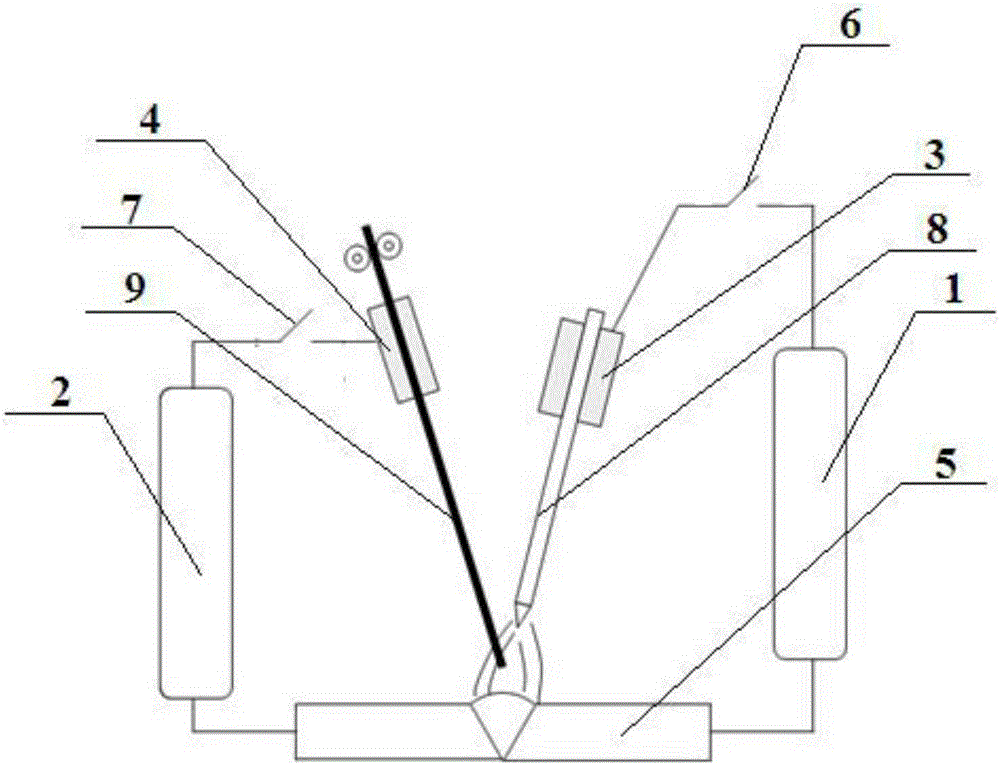

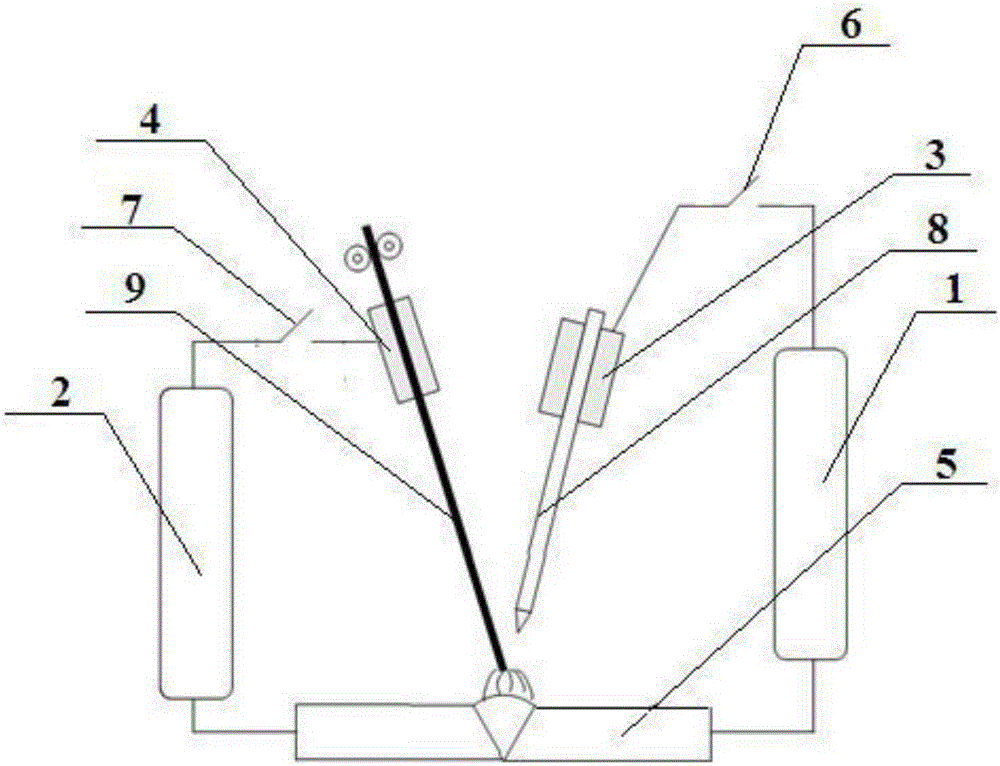

[0018] Specific implementation mode one: as figure 1 and figure 2 As shown, in this embodiment, an aluminum alloy TIG and MIG alternate composite welding method of the present invention is specifically carried out according to the following steps:

[0019] Connect the positive output end of the constant current TIG welding power source 1 to the workpiece 5 to be welded, connect the negative output end of the constant current TIG welding power source 1 to the tungsten electrode clamp 3, and clamp the TIG welding torch 8 on the tungsten electrode clamp 3. The gas shield on the side wall of the TIG welding torch 8 is provided with a melting electrode welding wire; the positive output terminal of the constant voltage MIG welding power supply 2 is connected to the melting electrode clamp 4, and the MIG welding torch 9 is clamped on the melting electrode clamp 4. The negative output terminal of the high-voltage MIG welding power supply 2 is connected to the workpiece 5 to be welde...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the nozzle of the TIG torch 8 is provided with a shielding gas channel, the shielding gas is a mixture of Ar and He or Ar; the shielding gas The feeding rate is 10~15L / min. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the tungsten electrode of the TIG welding torch 8 and the melting electrode of the MIG welding torch 9 form an included angle of 5°-30°. Others are the same as those in Embodiment 1 or 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap