A kind of diamond cutter and preparation method thereof, diamond composite cutter

A technology of diamond tools and diamond particles, which is applied in the tool manufacturing of sawing machines, metal sawing equipment, metal processing equipment, etc., can solve the problems of low utilization rate of diamond, low cutting efficiency of diamond tools, waste of diamond resources, etc. Automatic control, suitable for large-scale industrial production, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

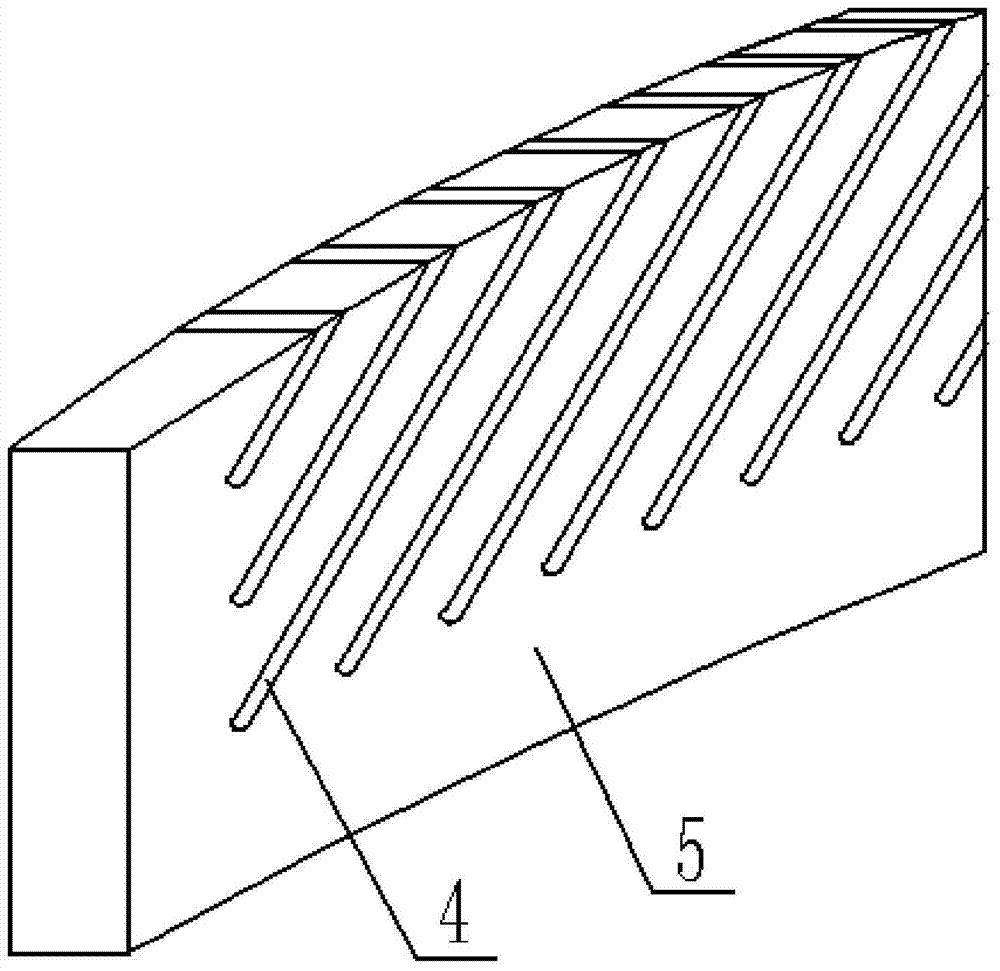

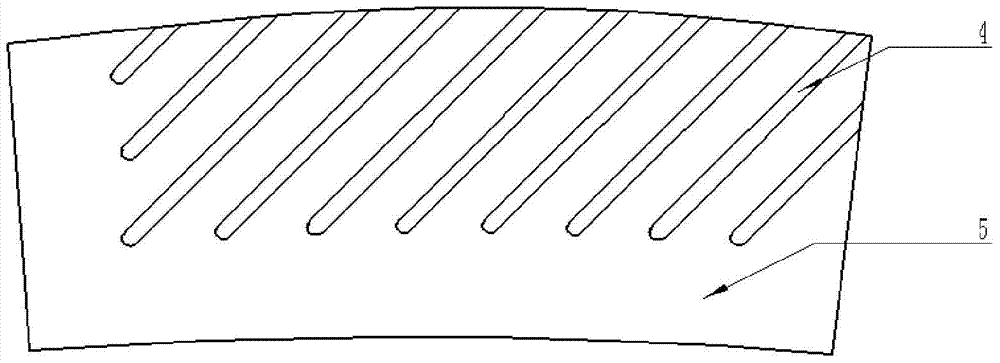

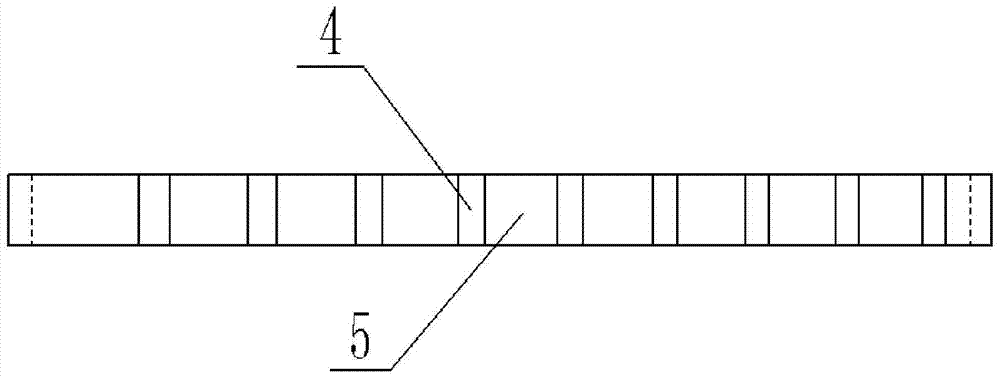

[0035] The diamond tool of the present embodiment, such as figure 1 , 2 , 3, including a cutter body 5, the cutting surface of the cutter body 5 is provided with a plurality of orderly arranged slits 4, and the slits 4 are arranged in parallel and all run through the front and rear sides of the cutter body 5; The angle between 4 and the bottom plane of the cutter body 5 is 45°, and the width of the slit 4 is 2mm; the distance between the bottom of the slit 4 and the bottom plane of the cutter body 5 is 5mm; the depth of the slit is 5mm; 3 / 4 of the body thickness; diamond particles are brazed and fixed in the slit 4.

[0036] The preparation method of the diamond tool of the present embodiment comprises the following steps:

[0037] 1) Open a slit with a slit width of 2mm on the cutter body by sawing to obtain a slit cutter body;

[0038] 2) After mixing the diamond particles and the brazing material, fill them into the slit of the slitting cutter body obtained in step 1) to...

Embodiment 2

[0041] The diamond cutter of this embodiment is the same as that of Embodiment 1, including a cutter body, and a plurality of orderly arranged slits are provided on the cutting surface of the cutter body, and the slits are arranged in parallel and all run through the front and rear sides of the cutter body; The angle between the slit and the bottom plane of the cutter body is 40°, the width of the slit is 0.5mm, and the distance between the bottom of the slit and the bottom plane of the cutter body is all the same, which is 1.5mm; There are diamond particles.

[0042] The preparation method of the diamond tool of the present embodiment comprises the following steps:

[0043] 1) Open a slit with a slit width of 0.5mm on the cutter body by sawing to obtain a slit cutter body;

[0044] 2) After mixing diamond particles and brazing material, fill them into the slit of the slitting cutter body obtained in step 1) to obtain a semi-finished product; the brazing material is a solder ...

Embodiment 3

[0047] The diamond composite tool of the present embodiment is a diamond saw blade, such as Figure 4 As shown, it includes a disc-shaped saw blade base 1, and the center of the saw blade base 1 is provided with a mounting hole 7 for mounting and matching with the rotating shaft and surrounding the mounting hole for positioning during installation. Positioning holes 3; the peripheral surface of the saw blade base 1 is spaced apart with chip removal grooves 6 running through the upper and lower ends of the saw blade substrate, and the peripheral surface of the saw blade base is welded between two adjacent chip removal grooves 6 for implementation. The diamond cutter 2 described in Example 1; the inclination directions of the slits on the diamond cutter 2 are consistent, clockwise or counterclockwise.

[0048] The preparation method of the diamond composite tool in this embodiment is to weld the diamond tool on the peripheral surface of the saw blade substrate, and the cutting s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com