A kind of active carbon material removes the method for processing antibiotic acesulfame

A technology of acesulfame and activated carbon, which is applied in chemical instruments and methods, adsorption water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high cost, secondary pollution, and limited application of chemical oxidation methods, and achieve the goal of preparing raw materials Cheap and easy to obtain, easy to operate, and the effect of simplifying industrial processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation and application steps of gac of the present invention are as follows:

[0027] 1. Preparation of activated carbon (AC) material

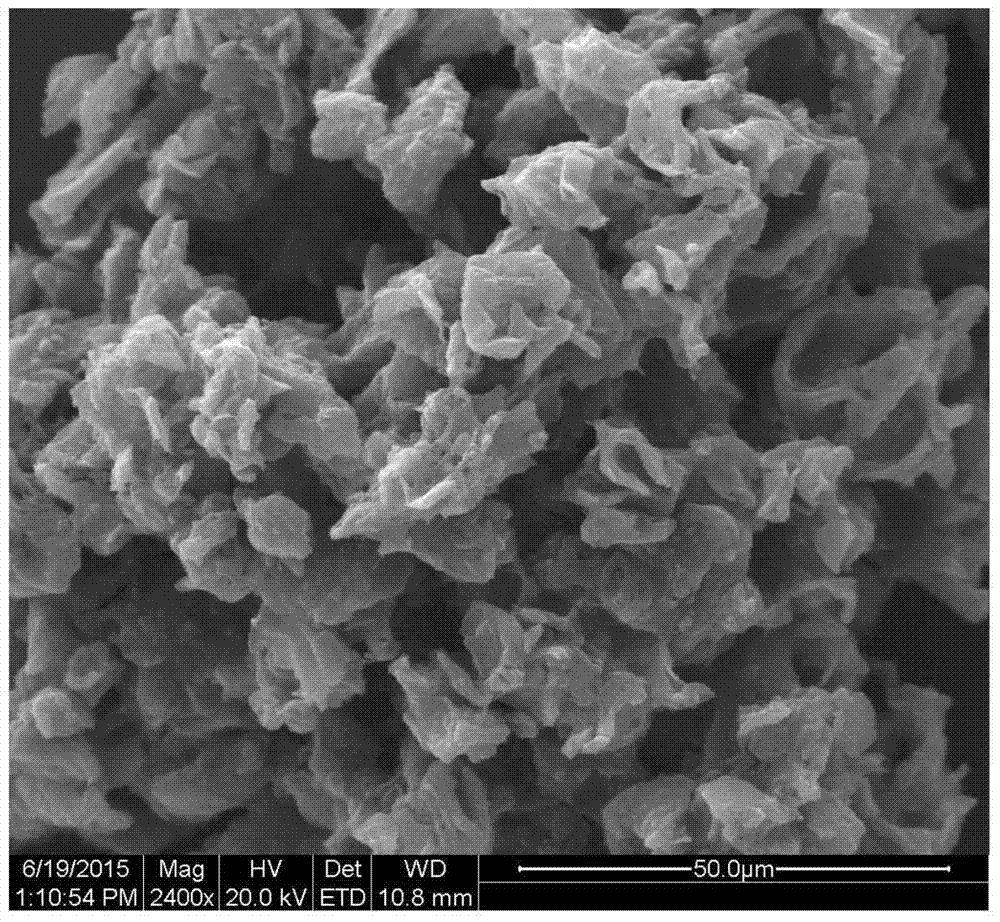

[0028] (1) Pretreatment of walnut shells: wash walnut shells with water to remove ash and gravel, put them in an oven and dry them at 80-85°C for 48 hours, and crush them to a particle size of 40-120 mesh to obtain walnut shell powder, which is stored in a desiccator spare.

[0029] (2)H 3 PO 4 Preparation of dipping material: Accurately weigh 5g of walnut shell powder that has been pulverized by a pulverizer and put it in a beaker, add 25mL H 3 PO 4 solution, H 3 PO 4 The ratio of walnut shell to mass is (1~4):1. After fully stirring, seal it, soak it in an oven at 90~95°C for 14.5~15.5h, remove the seal, dry it in an oven at 120~125°C for 12~13h, and stir it loosely. For example, stir once every 2 to 3 hours; after drying, H 3 PO 4 Dipping material.

[0030] (3) Preparation of activation material: H 3 PO 4 The im...

Embodiment 1

[0041] Preparation of activated carbon: Accurately weigh 5g of walnut shell powder pulverized by a pulverizer and place it in a beaker, add 25mL H 3 PO 4 solution, H 3 PO 4 The mass ratio of walnut shell to walnut shell is 4:1, fully stirred and then sealed, dipped in an oven at 90°C for 15 hours, removed the seal, dried in an oven at 120°C for 12 hours, and stirred every 2 hours to loosen, and after drying, H 3 PO 4 Dipping material. H 3 PO 4 The impregnated material is moved to the constant temperature section of the tube-type atmosphere furnace, and the temperature is raised to the experimentally set carbonization temperature of 250°C at a rate of 10°C / min. ℃, keep warm for 60min, after the reaction is completed, in N 2 Protect and cool down to room temperature to obtain the activated material, transfer the activated material to a conical flask, add 50mL of 1% HCl solution in mass concentration, place on a shaker and vibrate at 120r / min for 180min for pickling. Then...

Embodiment 2

[0047] In the preparation of H 3 PO 4 Dipping process, H 3 PO 4 The mass ratio to the walnut shell is 2:1, and other conditions and steps are the same as in Example 1 to obtain the target product activated carbon B.

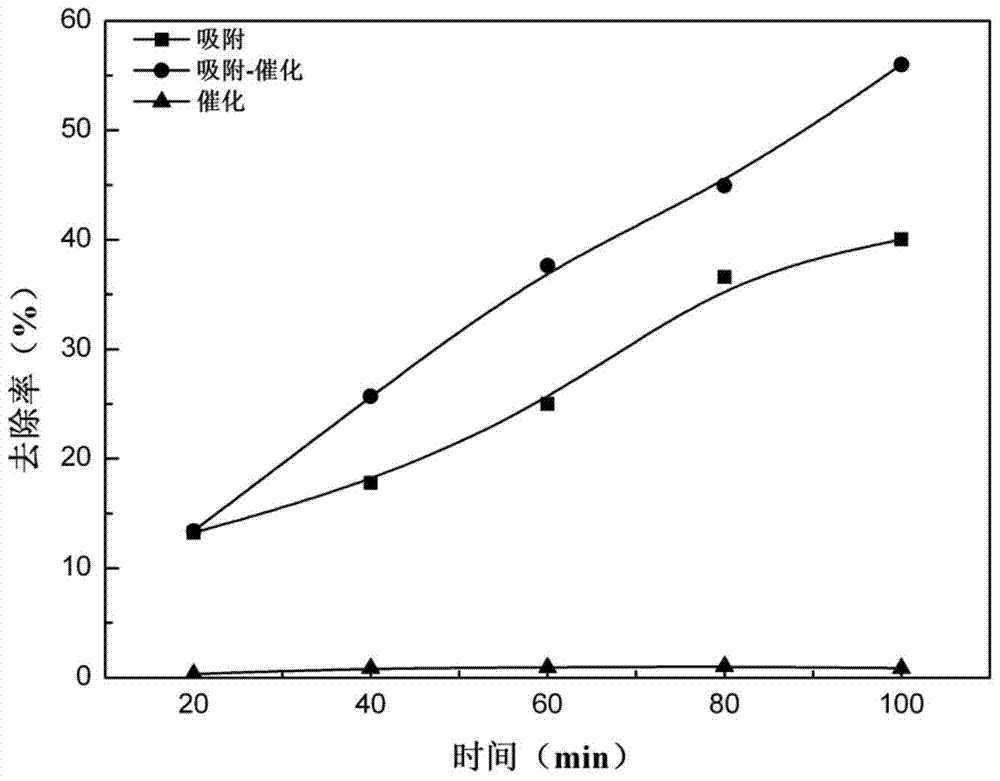

[0048] The target product activated carbon B is used to carry out adsorption treatment and adsorption-catalysis synergistic treatment on acesulfame, the conditions and steps are the same as in Example 1, the removal rate of acesulfame is calculated, and it is found that when only adsorption, the adsorption rate is 27.99%. Adsorption-catalysis When they work together, the degradation rate is 41.67%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com