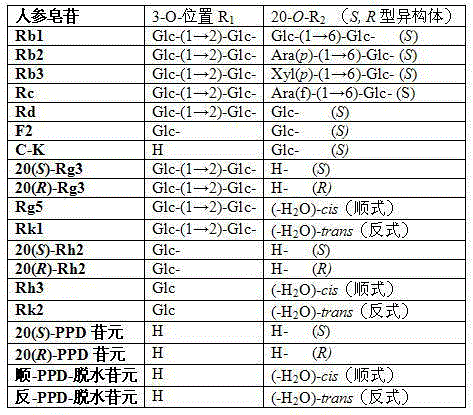

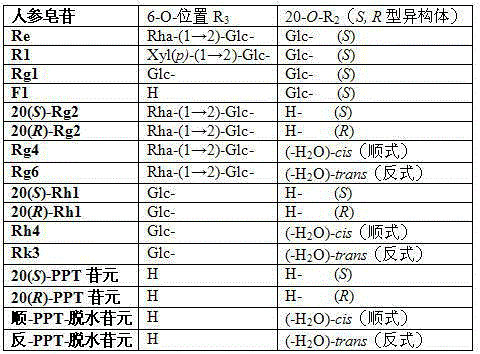

Preparation method of 20th carbon hydroxyl dehydrated ginseng rare saponin and aglycone

A technology of rare ginseng saponins and saponin aglycones, which is applied in the preparation of steroids, chemical instruments and methods, organic chemistry, etc., can solve the problems of inability to prepare saponins, and achieve the effects of low cost, high yield and purity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 6 grams of Rb1 saponin in 100 milliliters of n-butanol, 25 grams of FeCl2 (about 100 millimoles) in 100 milliliters of n-butanol, mix the two solutions, and react with stirring at 50 ° C for 20 hours; use 200 milliliters washed with water for 3 to 4 times to fully remove impurities such as salt ions and sugar, and dried under reduced pressure to obtain 4.1 grams of the product. Alternatively, the reaction liquid is collected by vacuum distillation to collect the organic solvent, and 150 ml of deionized water is added to the reactant to mix, and the saponin is repeatedly adsorbed by a macroporous adsorption resin with a volume of 150 ml, and then washed with 900 ml of water to remove impurities such as salt ions and sugar , and then 80% ethanol was used to elute the saponins, and the ethanol eluate was collected and dried to obtain 4.2 g of the product. Calculated by molar ratio, the conversion rate is greater than 90%. The reaction product was detected by TLC ...

Embodiment 2

[0021] Dissolve 3 g of F2 saponin in 100 mL of ethanol, 35 g of Al 2 (SO 4 ) 3 Dissolve in 100 milliliters of ethanol, mix the two solutions, and react at 25°C for 24 hours; collect the organic solvent by distillation under reduced pressure, add 70 milliliters of deionized water to the reactant, and then use 70 milliliters of water-saturated n-butanol to extract saponin and n-butanol. The butanol extraction operation was repeated three times; the n-butanol extracts were combined and washed 3-4 times with 70 ml of deionized water to fully wash off the inorganic salts and sugars generated by the reaction, and concentrated under reduced pressure to obtain 2.1 grams of rare saponins as a reaction product. Calculated by molar ratio, the conversion rate is greater than 90%. Its reaction product detects with TLC and HPLC method, compares with standard substance, more than 90% of product is the 20- of Rh2 saponin. O -Hydroxydehydrated highly active red ginseng rare saponins Rh3 and...

Embodiment 3

[0024] Dissolve 3 g of C-K saponins in 100 ml of methanol, 20 g of Mn(NO 3 ) 2Dissolved in 100 ml of methanol, mixed the two solutions, reacted at 25 ° C for 24 hours; added 100 ml of deionized water to mix, then extracted saponin with 200 ml of water-saturated n-butanol, and repeated n-butanol extraction three times; combined normal The butanol extract was washed 3-4 times with 300 milliliters of deionized water to fully wash off inorganic salts and sugars generated by the reaction, and concentrated under reduced pressure to obtain 2.1 grams of rare saponins as a reaction product. Calculated by molar ratio, the conversion rate is greater than 90%. Its reaction product detects with TLC and HPLC method, compares with standard substance, more than 90% of product is the 20- O -Hydroxydehydrated highly active red ginseng rare saponins cis-PPD(-H2O) and trans-PPD(-H2O).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com