Method for preparing SiBCN-containing thermally-polymerisable ceramic precursor

A ceramic precursor and thermal polymerization technology, which is applied in the field of preparation of thermally polymerizable ceramic precursors containing SiBCN, can solve problems such as limiting the processing performance of ceramic materials, harsh reaction conditions, and reducing ceramic yield, and achieves low cost and convenient experimental steps. The effect of less and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

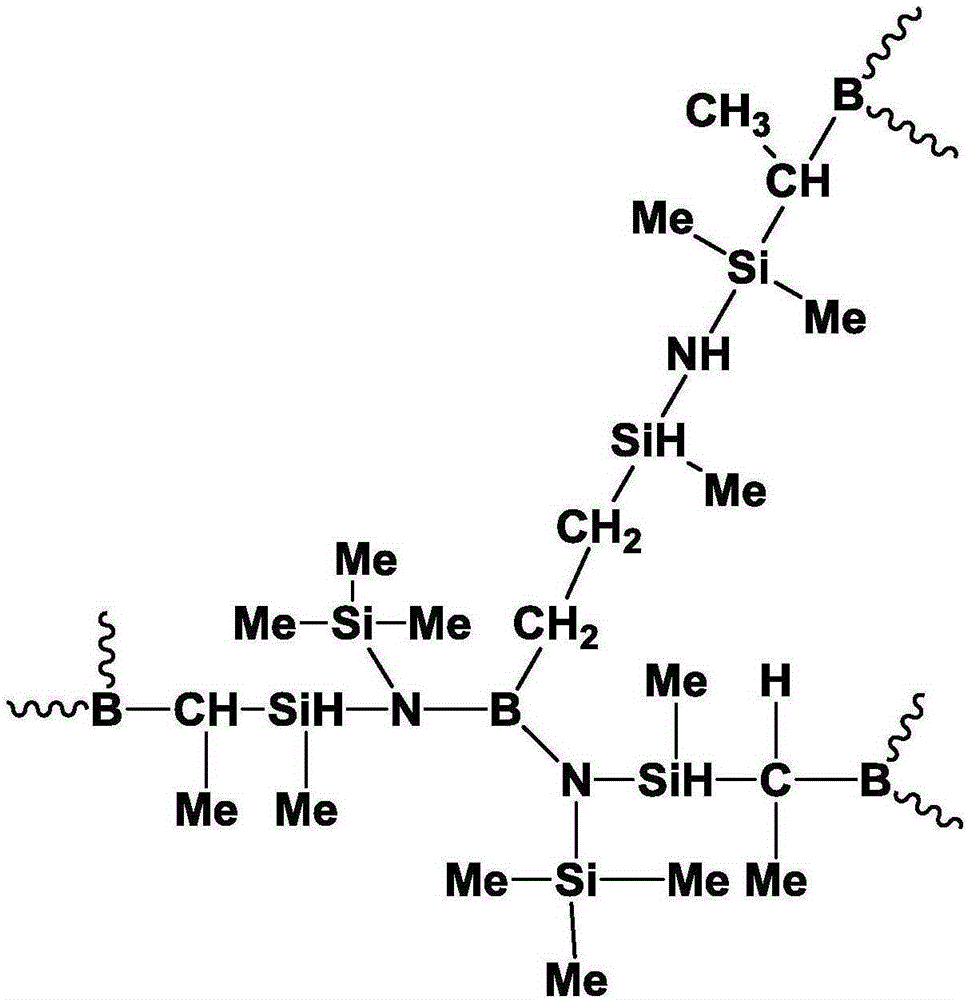

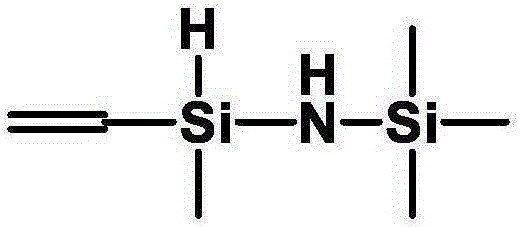

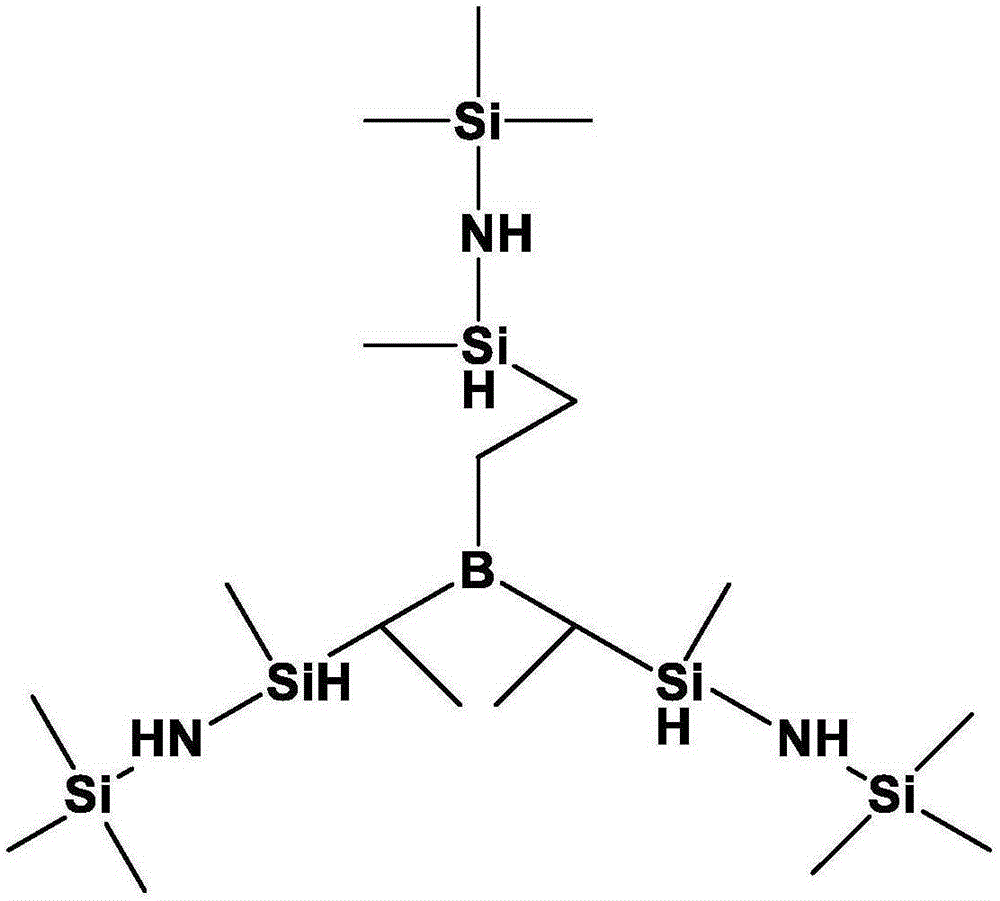

Image

Examples

Embodiment 1

[0029] Vacuum the Schlenk reaction bottle repeatedly, and fill it with dry argon at least three times to ensure that the air and moisture in the bottle are completely discharged, and inject 0.05 mol (7.0535 g) of vinyl dichlorosilane and 0.05 mol (8.0695 g) of hexamethyl The base disilazanes were sequentially added to the Schlenk reaction flask filled with an inert gas atmosphere in advance, and the stirrer was turned on to mix the raw materials evenly. After the injection, the temperature was raised to 45°C, stirred vigorously, and reacted for one day. Move the product obtained above to an ice bath and add the organic solvent anhydrous tetrahydrofuran. In order to avoid the reaction being too violent, it is necessary to add 0.05mol (1.8915g) NaBH in batches 4 After 12 hours of reaction, add 0.12mol (14.478g) dimethylvinylchlorosilane to continue the reaction for 12 hours, connect the distillation device, then raise the temperature to 60°C for 2 hours, then raise the temperatur...

Embodiment 2

[0031] Vacuum the Schlenk reaction bottle repeatedly, and fill it with dry argon at least three times to ensure that the air and moisture in the bottle are completely discharged. Use a syringe to inject 0.06mol (8.4642g) of vinyl dichlorosilane and 0.05mol (8.0695g) of hexamethyl The base disilazanes were sequentially added to the Schlenk reaction flask filled with an inert gas atmosphere in advance, and the stirrer was turned on to mix the raw materials evenly. After the injection, the temperature was raised to 45°C, stirred vigorously, and reacted for one day. Move the product obtained above to an ice bath and add the organic solvent anhydrous tetrahydrofuran. In order to avoid the reaction being too violent, it is necessary to add 0.06mol (2.2698g) NaBH in batches 4 After 12 hours of reaction, add 0.144mol (17.3736g) dimethylvinylchlorosilane to continue the reaction for 12 hours, connect the distillation device, then raise the temperature to 60°C for 2 hours, then raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com