Preparation method for modified carbon-fiber-reinforced polyether ether ketone composite material

A polyetheretherketone, fiber-reinforced technology is applied in the field of polymer material preparation, which can solve the problems of carbon fiber surface structure damage, fiber body strength reduction, and inability to continuously produce, etc., to enhance mechanical bonding ability, reduce strength, and improve wettability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

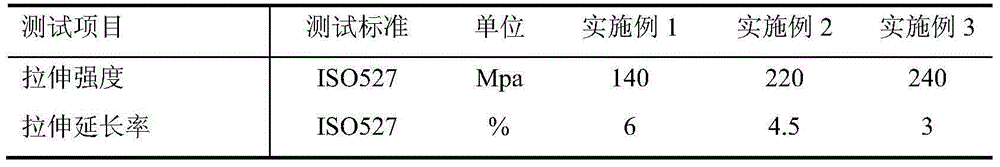

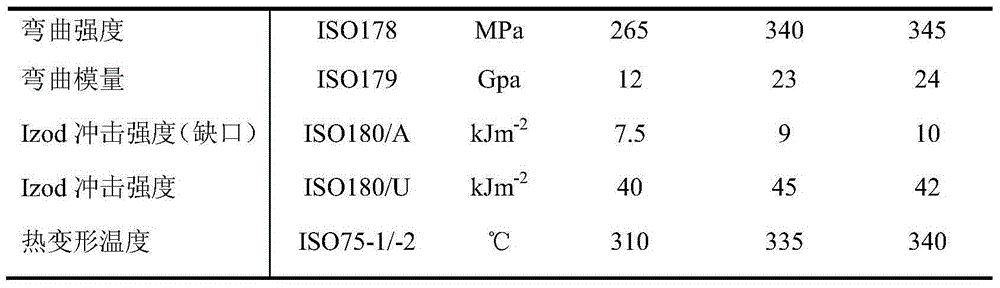

Embodiment 1

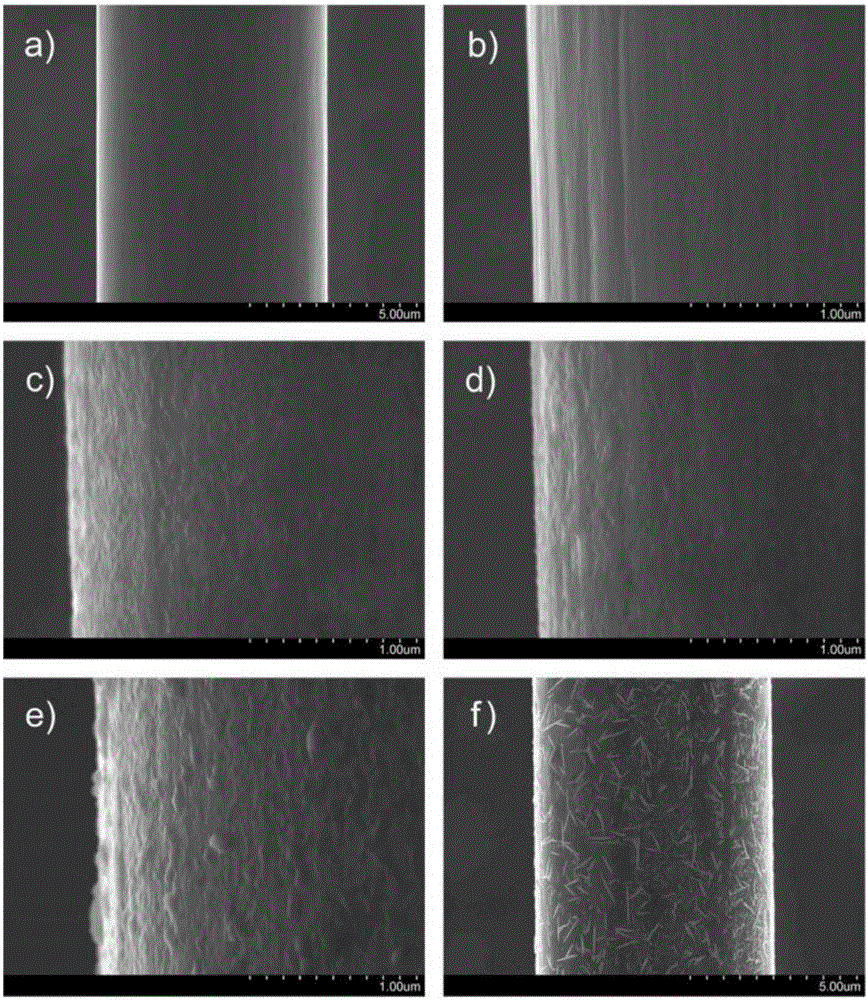

[0031] (1) Surface activation of carbon fiber

[0032] Use acetone as the extraction solution, heat to 80°C, soak the carbon fiber tow in the extraction solution, ultrasonicate for 2 hours, and mechanically stir for 2 hours, then filter and rinse with a large amount of deionized water, and dry to obtain degummed carbon fiber;

[0033] Soak 100 g of degummed carbon fibers in 5 L of 1.5% water / p-phenylenediamine mixed solution (p-phenylenediamine 0.69 mol), heat to 80° C., and mechanically stir. While stirring, slowly add 40 g (0.345 mol) of isoamyl nitrite. After completion, continue to stir at 80°C for 12 hours, filter and rinse with a large amount of deionized water to obtain aniline-activated carbon fibers;

[0034] (2) Nanoparticles loaded on carbon fiber surface

[0035] 1g of graphene is dispersed in 5L of water by ultrasonic method, 100g of aniline activated carbon fiber is soaked in the graphene dispersion liquid, heated to 80 ℃ and under the condition of stirring, sl...

Embodiment 2

[0044] (1) Surface activation of carbon fiber

[0045] Use acetone / N'N-dimethylformamide mixed solution as the extraction solution, heat to 75°C, soak the carbon fiber tow in the extraction solution, stir it mechanically for 8 hours, then filter and rinse with a large amount of deionized water, and dry it to get Degumming carbon fiber;

[0046] Soak 100 g of degummed carbon fibers in 5 L of 3% water / p-phenylenediamine (1.38 mol p-phenylenediamine) mixed solution, heat to 90° C., and stir mechanically. Under stirring conditions, slowly add 80 g (0.69 mol) of isoamyl nitrite. After completion, continue to stir at 90° C. for 12 h, filter and rinse with a large amount of deionized water to obtain aniline-activated carbon fibers.

[0047] (2) Nanoparticles loaded on carbon fiber surface

[0048] Disperse 1g of multi-walled carbon nanotubes in 5L of water by ultrasound, soak 100g of aniline-activated carbon fibers in the graphene dispersion, heat to 80°C and slowly add 0.5g of is...

Embodiment 3

[0057] (1) Surface activation of carbon fiber

[0058] Use acetone as the extraction solution, heat to 85°C, soak the carbon fiber tow in the extraction solution, ultrasonicate for 2 hours, then filter and rinse with a large amount of deionized water, and dry to obtain the degummed carbon fiber;

[0059] Soak 100 g of degummed carbon fiber in 5 L of 2.5% water / p-phenylenediamine mixture (1.16 mol p-phenylenediamine), heat to 70° C., and stir mechanically. Under stirring conditions, 67.7 g (0.58 mol) of isoamyl nitrite was slowly added. After completion, continue to stir at 70°C for 12 hours, filter and rinse with a large amount of deionized water to obtain aniline-activated carbon fibers;

[0060] (2) Nanoparticles loaded on carbon fiber surface

[0061] Disperse 1g of graphene oxide in 5L of water by ultrasonic method, soak 100g of aniline activated carbon fiber in the dispersion of graphene, heat to 75°C and slowly add 0.5g of isoamyl nitrite while stirring, And stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com