Method for microwave assisted low temperature squeezing apium graveolens seed oil

A celery seed oil, microwave-assisted technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problem of high cost, achieve pure color, maintain natural flavor, no chemical residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Material selection, impurity removal and drying: Wash the celery seeds with clean water to remove dust, soil and other impurities, and then put them in the sun to dry until the moisture content reaches 4%.

[0015] 2. Microwave: Put a certain amount of celery seeds in a microwave oven, and use 700W microwave treatment for 60s.

[0016] 3. Oil extraction: Select a slag outlet with a nozzle diameter of 4 mm, assemble a low-temperature press (purchased from IBG, Germany, model KOMET-CA59G), and preheat the low-temperature press for about 30 seconds to keep the temperature of the slag outlet At 56°C, the controlled rotation speed is 18.6rpm, and low-temperature pressing is carried out.

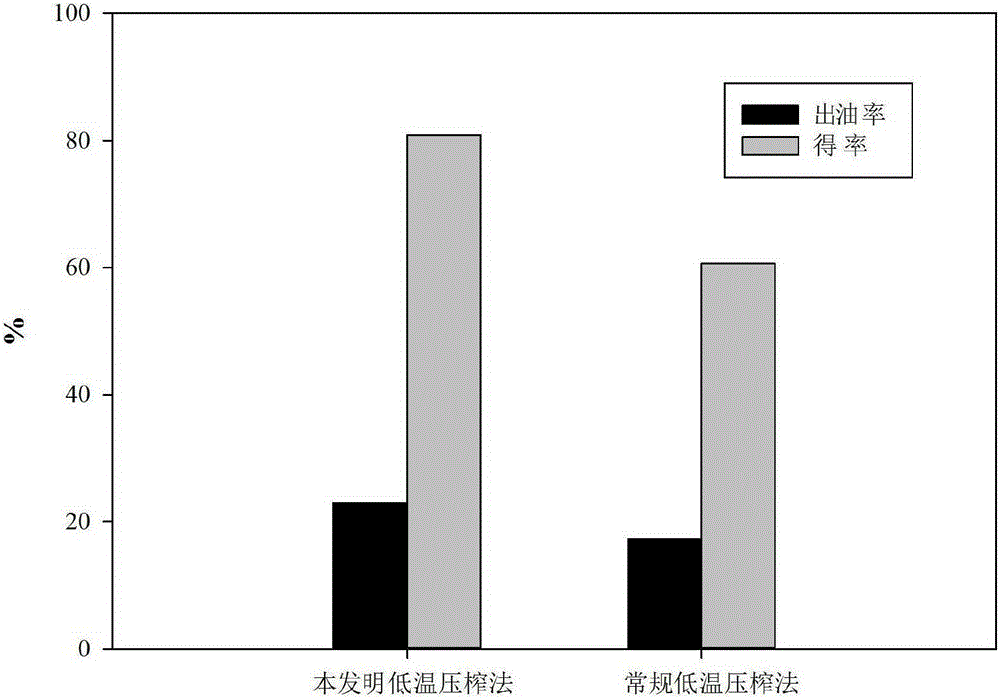

[0017] 4. Filtration: the oil pressed at low temperature is centrifuged (3500r / min, 15min), filtered with three layers of gauze to obtain clean celery seed oil, and the celery seed oil yield is 22.98% at this moment.

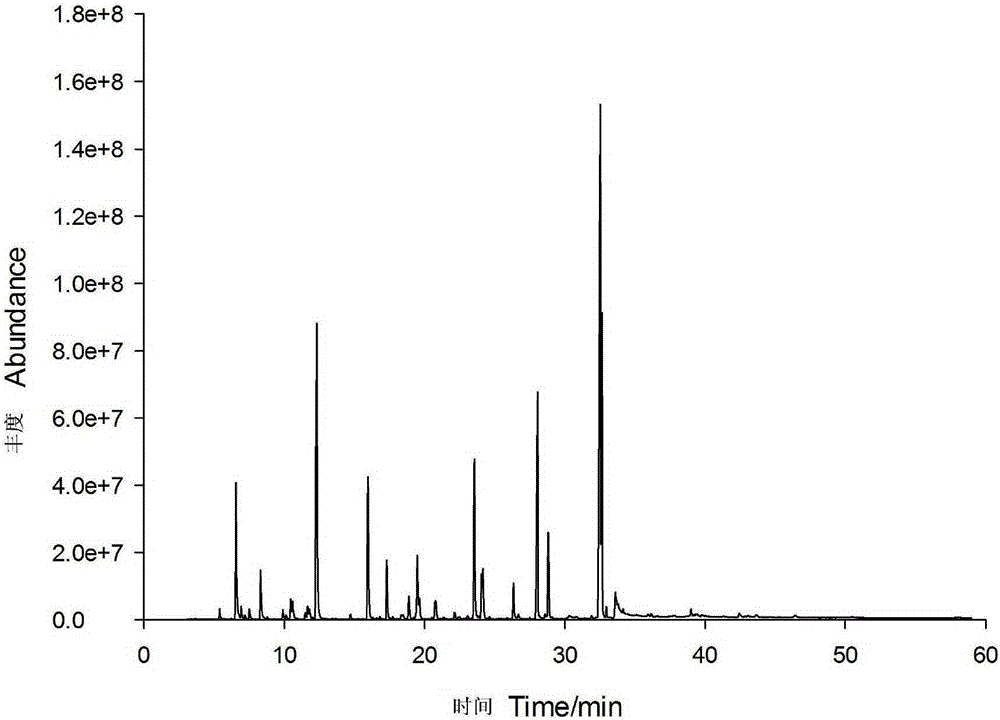

[0018] Volatile components of celery seed oil see figure 1 and Tabl...

Embodiment 2

[0025] 1. Material selection, impurity removal and drying: Wash the celery seeds with clean water to remove dust, soil and other impurities, and then put them in the sun to dry until the moisture content reaches 5%.

[0026] 2. Microwave: Put a certain amount of celery seeds in a microwave oven, and use 400W microwave treatment for 120s.

[0027] 3. Oil extraction: Select a slag outlet with a nozzle diameter of 4mm, assemble a KOMET-CA59G low-temperature press, preheat the low-temperature press for about 30 seconds, keep the temperature of the slag outlet at 55°C, control the speed at 16.3rpm, and perform low-temperature press.

[0028] 4. Filtration: the oil pressed at low temperature is centrifuged (3500r / min, 15min), filtered with three layers of gauze to obtain clean celery seed oil, and now the celery seed oil yield is 19.88%.

Embodiment 3

[0030] 1. Material selection, impurity removal and drying: Wash the celery seeds with clean water to remove dust, soil and other impurities, and then put them in the sun to dry until the moisture content reaches 5%.

[0031] 2. Microwave: Put a certain amount of celery seeds in a microwave oven, and use 550W microwave treatment for 90s.

[0032] 3. Oil extraction: Select a slag outlet with a nozzle diameter of 4mm, assemble a KOMET-CA59G low-temperature press, preheat the low-temperature press for about 30 seconds, keep the temperature of the slag outlet at 60°C, control the speed at 27.6rpm, and perform low-temperature press.

[0033] 4. Filtration: the oil pressed at low temperature is centrifuged (3500r / min, 15min), filtered with three layers of gauze to obtain clean celery seed oil, and now the celery seed oil yield is 19.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com