Method for preparing ginger wine by using ultrasonic compound enzyme technology

A composite enzyme and ultrasonic technology, applied in microorganism-based methods, biochemical equipment and methods, preparation of alcoholic beverages, etc., can solve the problems of low extraction rate of functional components of ginger wine, low antioxidant activity, and low technological content. , to achieve the effect of rich aroma components, reducing steps such as leaching, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

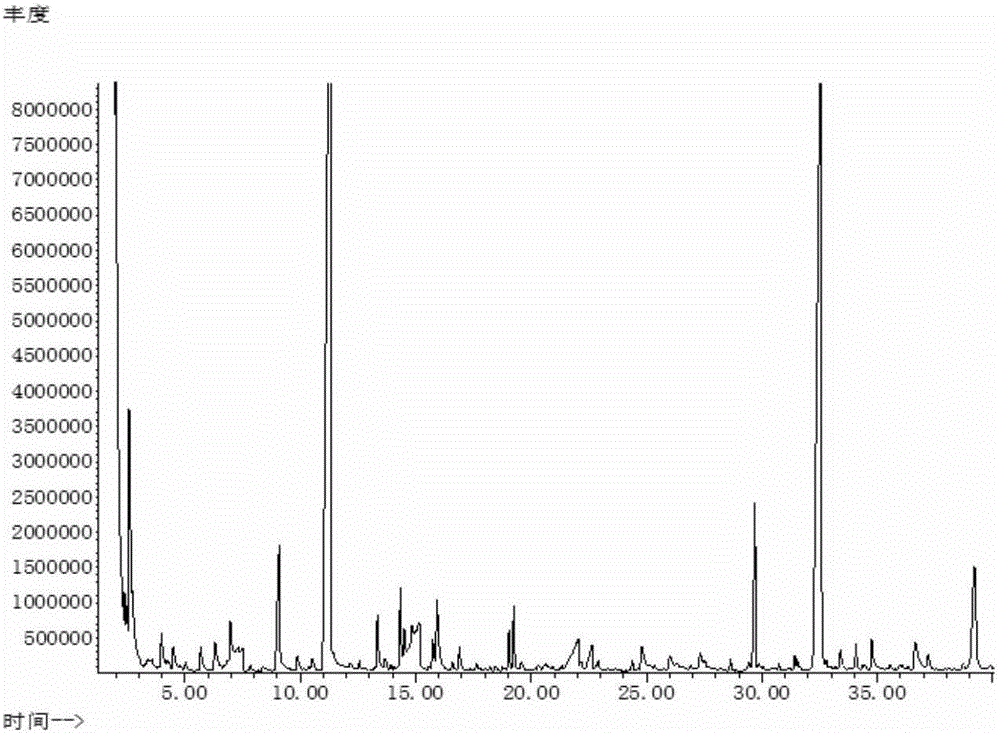

[0035] Example 1: Production of ginger wine by fermentation with ultrasonic compound enzyme technology

[0036] (1) Select fresh, mildew-free, non-rotten, and fleshy ginger, after cleaning and cutting into pieces, mash it into a homogenous substance in a beater, and put it in a beaker for later use; add pure water, adjust the ingredients The liquid ratio is 1:3g / mL (that is, every 3mL feed liquid contains 1g ginger), add 400U / g cellulase, 600U / g pectinase, 55U / g α-amylase, and then put it into an ultrasonic extractor, Set the ultrasonic specific power to 5W / g, the ultrasonic temperature to 45°C, and the ultrasonic time to 15 minutes to obtain the ginger juice extract after the ultrasonic compound enzyme co-treatment; after the obtained ginger juice extract was treated in a 90°C water bath for 30s to inactivate the enzyme, after 4 Filter with a layer of filter cloth, centrifuge at 5000r / min for 5min and take the supernatant;

[0037] (2) Adjust the sugar of the obtained supern...

Embodiment 2

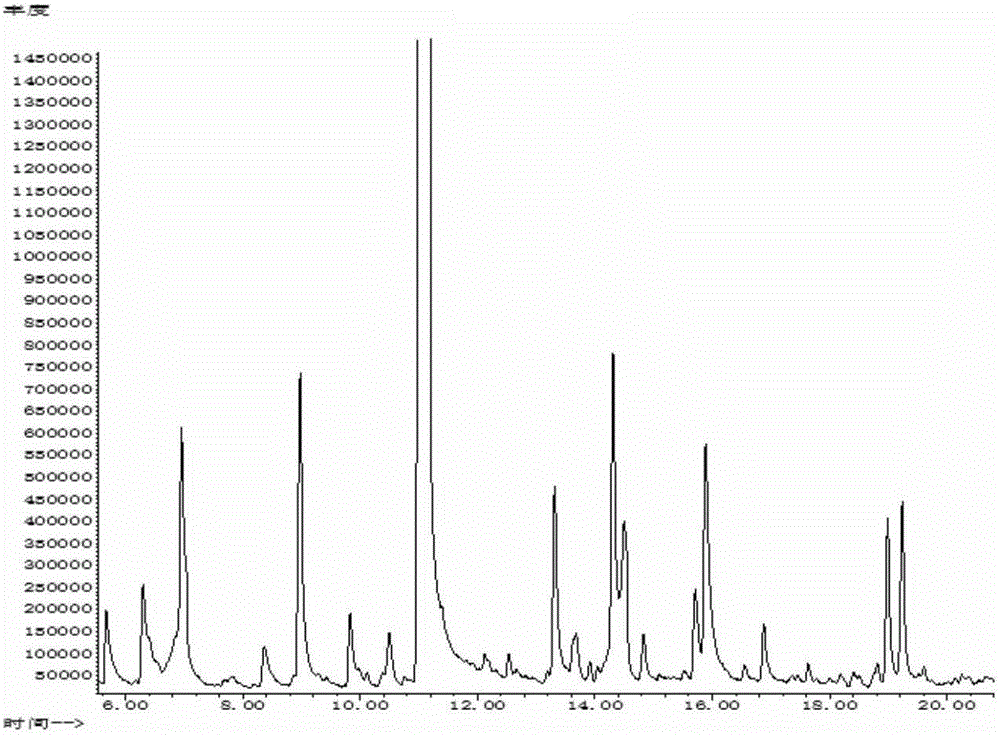

[0041] Embodiment 2: Fermentation production of ginger wine by ultrasonic composite enzyme technology

[0042] (1) Select fresh, mildew-free, non-rotten, and fleshy ginger, after cleaning and cutting into pieces, mash it into a homogenous substance in a beater, and put it in a beaker for later use; add pure water, adjust the ingredients The liquid ratio is 1:2g / mL, add 200U / g cellulase, 400U / g pectinase, 35U / g α-amylase, put it into the ultrasonic extractor, set the ultrasonic specific power to 3W / g, and the ultrasonic temperature to 35°C , ultrasonic time 10min, to obtain the ginger juice extract after ultrasonic complex enzyme co-treatment; the obtained ginger juice extract was treated in a 90°C water bath for 30s to inactivate the enzyme, filtered through 4 layers of filter cloth, centrifuged at 5000r / min for 5min, and then taken supernatant;

[0043] (2) Adjust the sugar of the obtained supernatant to 15°Brix, and then place it in an autoclave with a pressure of 0.1MPa an...

Embodiment 3

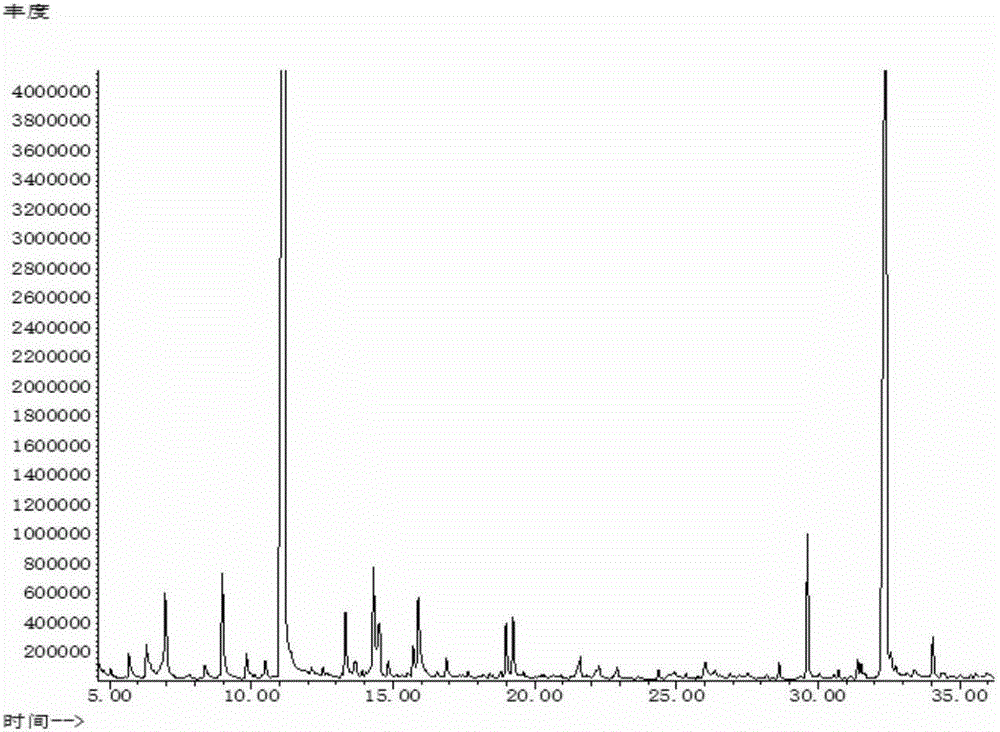

[0047] Embodiment 3: Fermentation production of ginger wine by ultrasonic compound enzyme technology

[0048] (1) Select fresh, mildew-free, non-rotten, and fleshy ginger, after cleaning and cutting into pieces, mash it into a homogenous substance in a beater, and put it in a beaker for later use; add pure water, adjust the ingredients The liquid ratio is 1:5g / mL, add 300U / g cellulase, 500U / g pectinase, 45U / g α-amylase, and then put it into the ultrasonic extractor, set the ultrasonic specific power to 4W / g, and the ultrasonic temperature to 40 ℃, ultrasonic time 12min, to obtain the ginger juice extract after the co-treatment of ultrasonic complex enzyme; after the obtained ginger juice extract was treated in a 90℃ water bath for 30s to inactivate the enzyme, filtered through 4 layers of filter cloth, and centrifuged at 5000r / min for 5min Take the supernatant;

[0049] (2) Adjust the sugar of the obtained supernatant to 15°Brix, and then place it in an autoclave with a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com