Method for processing materials with high zinc, lead and bismuth through enriched-oxygen side-blown molten pool double-smelting furnace

A smelting furnace and melting pool technology, applied in the direction of improving process efficiency, etc., can solve problems affecting the normal operation of fuming furnaces, high investment costs of fuming furnaces, and poor utilization, etc., to achieve good environment, easy operation, and resources saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

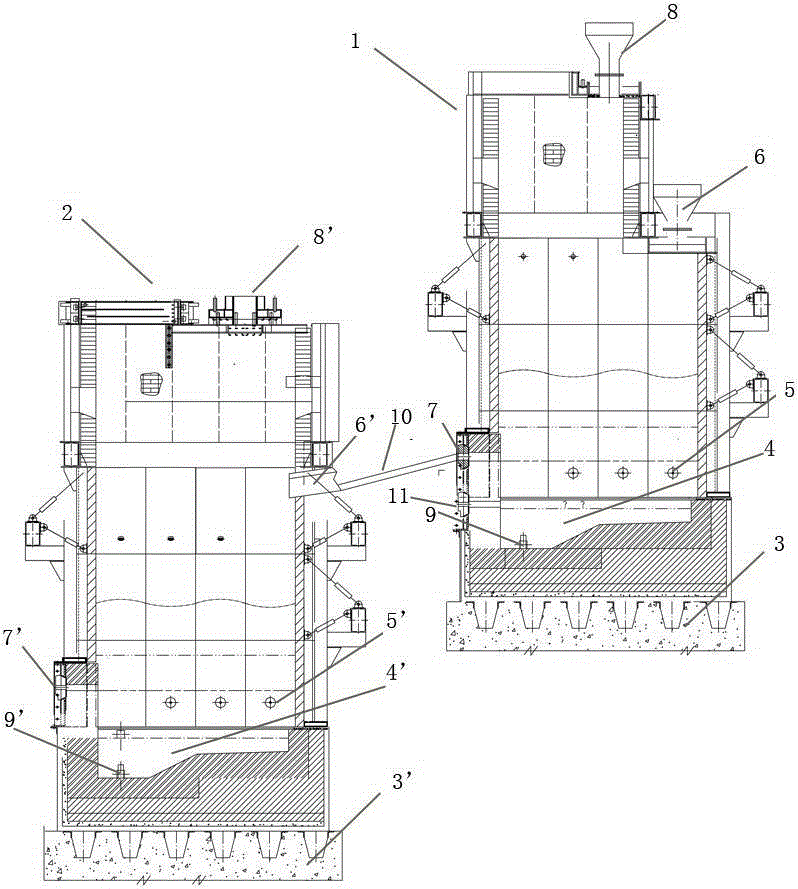

[0011] A method for treating high zinc, lead and bismuth materials with an oxygen-enriched side-blown molten pool double smelting furnace. The oxygen-enriched side-blown molten pool double smelting furnace is divided into two parts: oxidation furnace body (1) and reduction furnace body (2) ; Both furnace bodies are equipped with independent furnace base (3, 3'), hearth (4, 4'), water jacket, tuyere (5, 5'), siphon port, feed port (6, 6'), discharge port (7, 7') and flue port (8, 8'); the lowest part of the hearth (4, 4') in the two furnace bodies is also equipped with safety ports (9, 9') ), used to empty the furnace body materials when the furnace is shut down for maintenance; the furnace base (3, 3') of the oxidation furnace body (1) is located higher than the furnace base (3) of the reduction furnace body (2) , 3') On the base surface, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com