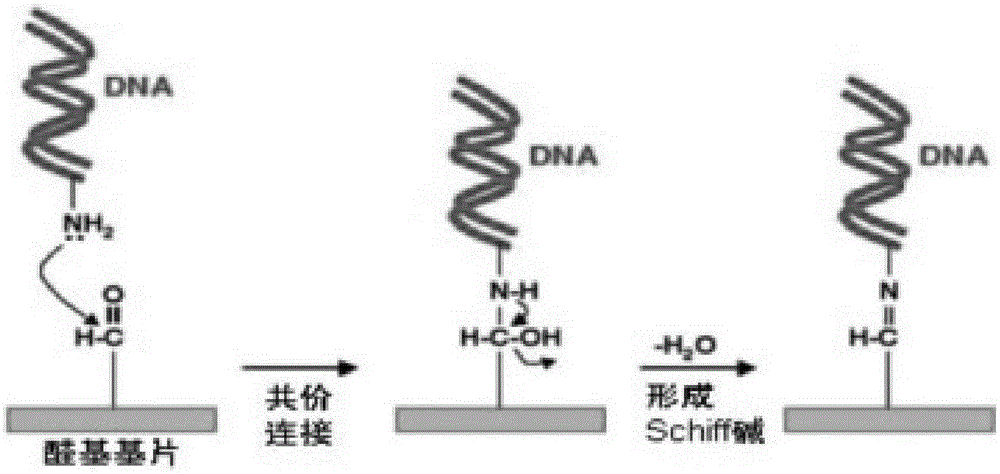

Active aldehyde group modified substrate applied to microarray and preparation method of active aldehyde group modified substrate

A technology of aldehyde group modification and microarray, which is applied in the fields of medicine and biology to achieve uniform surface, high probe immobilization rate, and improved immobilization force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

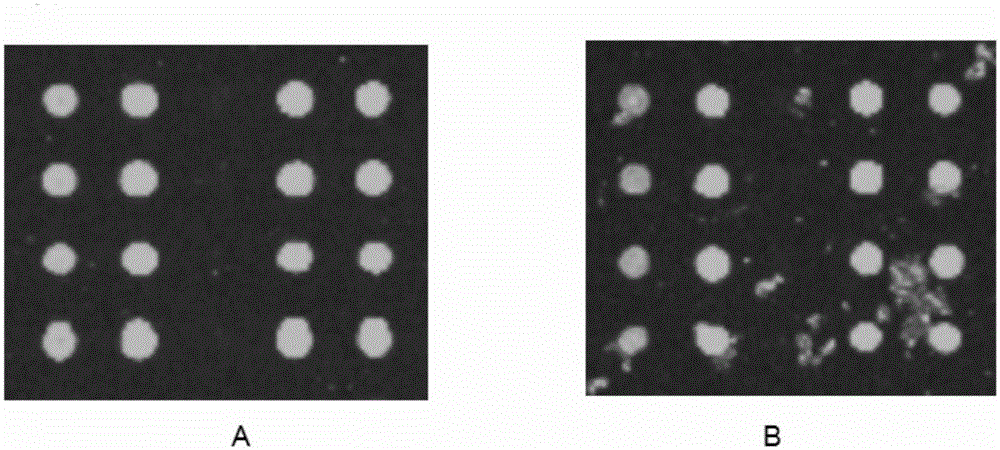

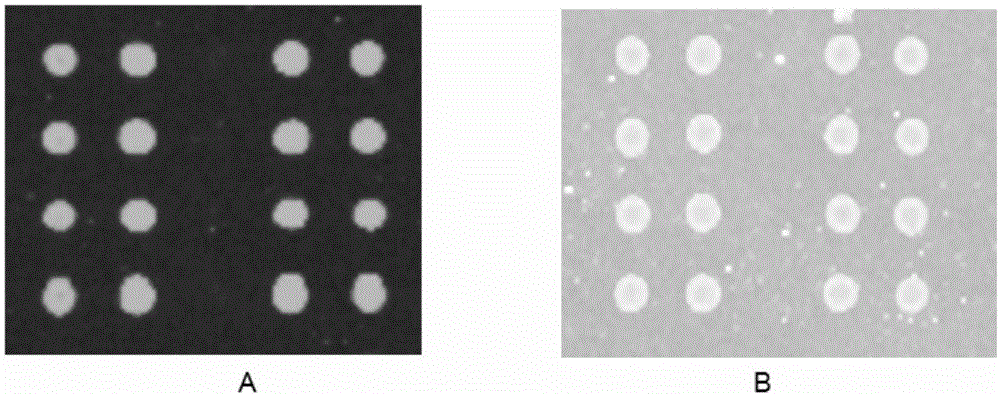

Examples

Embodiment 1

[0043] A method for preparing a microarray with an active aldehyde group-modified substrate, comprising the steps of:

[0044] Step (1), pretreatment of the slides: clean the slides once with a plasma cleaner for 5 minutes, then soak and wash the slides with concentrated sulfuric acid with a mass concentration of 98% for 1 hour, and then clean the slides with purified water. Wash the residual concentrated sulfuric acid on the surface to obtain the pretreated glass slide;

[0045] Step (2), poly-lysine coating: Coat the surface of the pretreated glass slide obtained in step (1) with poly-lysine, when coating poly-lysine, use a mass concentration of 0.5% The polylysine aqueous solution soaked the slides for 10 minutes, then washed off the excess uncoated polylysine on the surface of the slides with purified water, dried at 55°C for 30 minutes, cooled to room temperature, and obtained Polylysine-coated slides;

[0046] Step (3), introducing active aldehyde groups; using glutara...

Embodiment 2

[0048] A method for preparing a microarray with an active aldehyde group-modified substrate, comprising the steps of:

[0049] Step (1), pretreatment of the slides: the slides were first cleaned continuously with a plasma cleaner for 5 times, each time for 5 minutes, and then soaked in concentrated sulfuric acid with a mass concentration of 98% for 2 hours, and then the slides were cleaned with purified water. Wash the residual concentrated sulfuric acid on the surface to obtain the pretreated glass slide;

[0050] Step (2), poly-lysine coating: Coat the surface of the pretreated glass slide obtained in step (1) with poly-lysine, when coating poly-lysine, use a mass concentration of 1.5% The polylysine aqueous solution soaked the slides for 30 minutes, then washed off the excess uncoated polylysine on the surface of the slides with purified water, dried at 65°C for 60 minutes, cooled to room temperature, and obtained Polylysine-coated slides;

[0051] Step (3), introducing a...

Embodiment 3

[0053] A method for preparing a microarray with an active aldehyde group-modified substrate, comprising the steps of:

[0054] Step (1), pretreatment of the slides: the slides were first cleaned by a plasma cleaner for 3 consecutive times, each time for 3 minutes, and then soaked in concentrated sulfuric acid with a mass concentration of 98% for 1.6 hours, and then the slides were cleaned with purified water. Wash the residual concentrated sulfuric acid on the surface to obtain the pretreated glass slide;

[0055] Step (2), poly-lysine coating: Coat the surface of the pretreated glass slide obtained in step (1) with poly-lysine, when coating poly-lysine, use a mass concentration of 1.2% The polylysine aqueous solution soaked the slides for 18 minutes, then washed off the excess uncoated polylysine on the surface of the slides with purified water, dried at 60°C for 45 minutes, cooled to room temperature, and obtained Polylysine-coated slides;

[0056] Step (3), introducing ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com