Method for separating nano particles of different particle sizes

A nanoparticle and particle size technology, applied in the field of separation, can solve problems such as poor selectivity, difficult selection of surfactants, unpredictable particle size of nanoparticles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

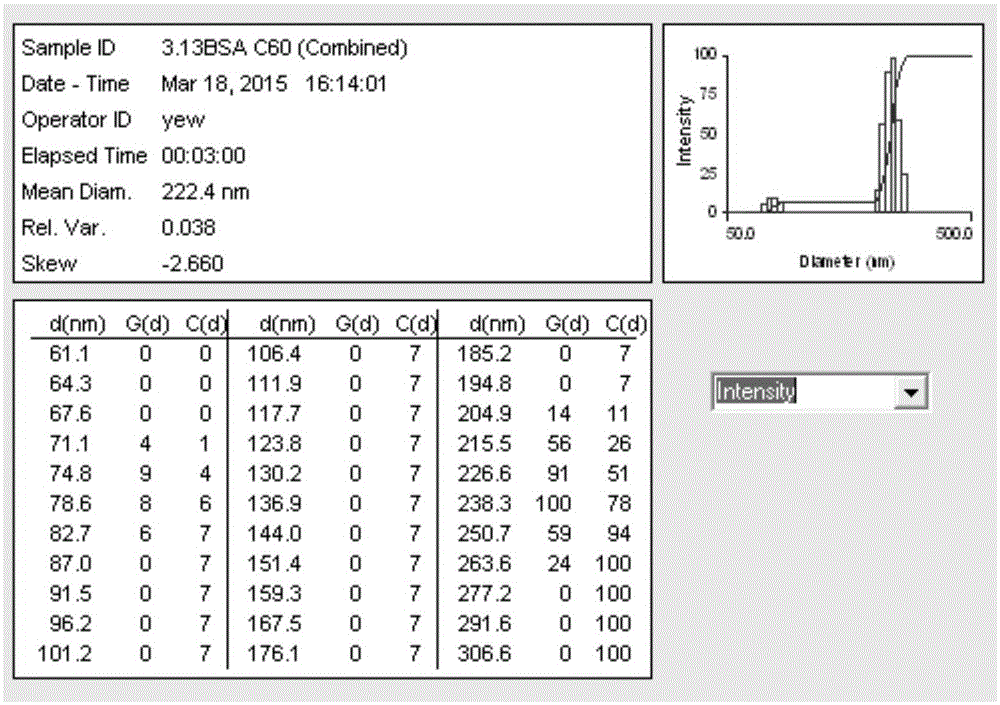

[0062] (1) 0.2639g (weighed by an analytical balance) of nano-tantalum powder (measured by the method of (1)) has a particle size of 61.1-306.6nm, and its particle size diagram is as follows figure 1 shown) in 50mL of ethylene glycol, fully dispersed in an ultrasonic machine for 30 minutes, and then put the dispersed mixture into a centrifuge tube;

[0063] (2) Centrifuge for 30 minutes at a speed of 1000 rpm;

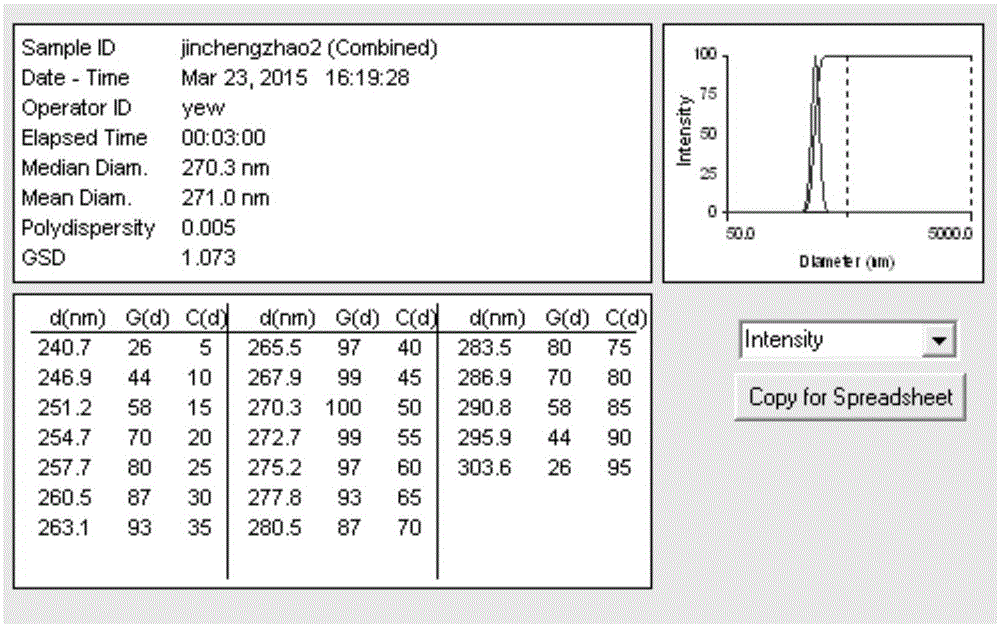

[0064] (3) Remove the supernatant liquid from the separation system, wash the sediment obtained by centrifugation with absolute ethanol three times, vacuum-dry it at 40°C for 1 hour, and then ultrasonically disperse it in absolute ethanol, then use the method (1) to measure The particle size of the sediment is 240.7~303.6nm, the particle size diagram is as follows figure 2 shown;

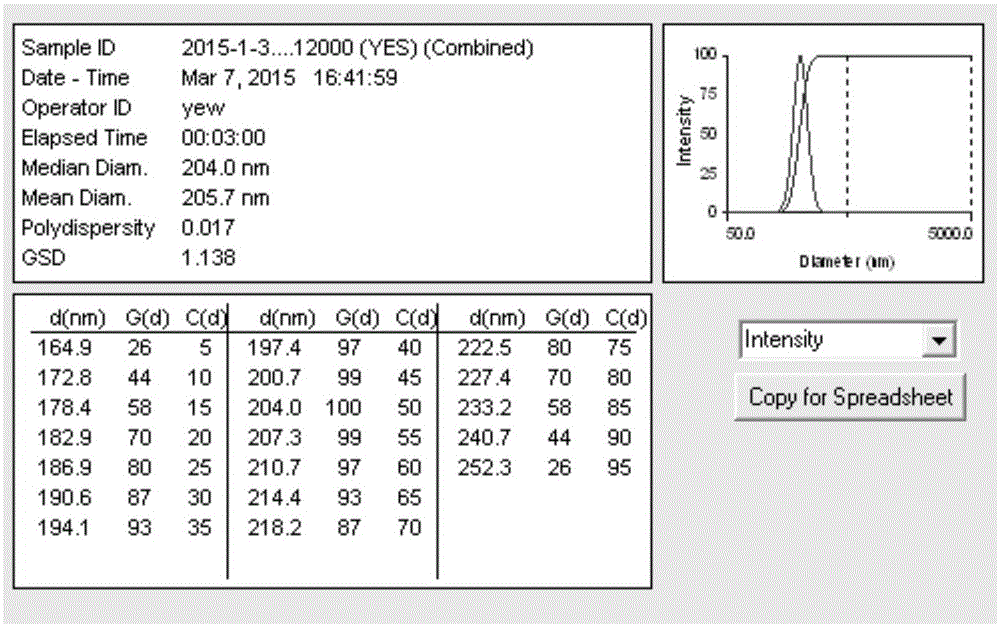

[0065] (4) The supernatant liquid continues to be centrifuged at 1500rpm, 2000rpm and 2500rpm respectively for 30 minutes, repeating the operations of steps 2 to 3 above until the superna...

Embodiment 2

[0071] (1) Disperse 0.3998g (weighed by an analytical balance) of nano-tantalum powder (the particle diameter is 60.1 to 310.6nm as measured by method (1)) in 50mL of n-decyl alcohol, fully disperse in an ultrasonic machine for 30 minutes, Then put the dispersed mixed solution in a centrifuge tube;

[0072] (2) Centrifuge for 40 minutes under the condition of 800 rpm;

[0073] (3) Remove the supernatant from the separation system, wash the sediment obtained by centrifugation with absolute ethanol three times, vacuum-dry it at 40°C for 1 hour, and then ultrasonically disperse it in absolute ethanol, then use the method (1) to measure The particle size of the sediment is 250-310nm;

[0074] (4) The supernatant liquid continues to be centrifuged for 40 minutes under the condition of rotating speed of 1300rpm, 1800rpm and 2300rpm respectively, and the operation of steps 2 to 3 above is repeated until the supernatant liquid is clarified, that is, the minimum particle size of the p...

Embodiment 3

[0079] (1) Disperse 0.1325g (weighed by an analytical balance) of nano-tantalum powder (the particle size is 20.5-400.3nm measured by the method (1)) in 50mL ethanol-glycerol composite solvent (viscosity is 100mPa.S) , fully disperse in an ultrasonic machine for 30 minutes, and then put the dispersed mixture into a centrifuge tube;

[0080] (2) Centrifuge for 20 minutes under the condition of 1200rpm at a rotating speed;

[0081] (3) Remove the supernatant from the separation system, wash the sediment obtained by centrifugation with absolute ethanol three times, vacuum-dry it at 40°C for 1 hour, and then ultrasonically disperse it in absolute ethanol, then use the method (1) to measure The particle size of the sediment is 150-200nm;

[0082] (4) The supernatant liquid continues to be centrifuged at 1700rpm, 2200rpm and 2700rpm respectively for 20 minutes, and repeats the operations of steps 2 to 3 above until the supernatant is clarified, that is, the minimum particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com