a timing belt

A technology of synchronous belt and skeleton, applied in the field of belt transmission, can solve the problems such as the need to improve the heat resistance performance, the reduced reliability of the synchronous belt, and the insufficient service life of the synchronous belt, and achieve excellent physical and mechanical properties, improved mechanical properties, and excellent physical and mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

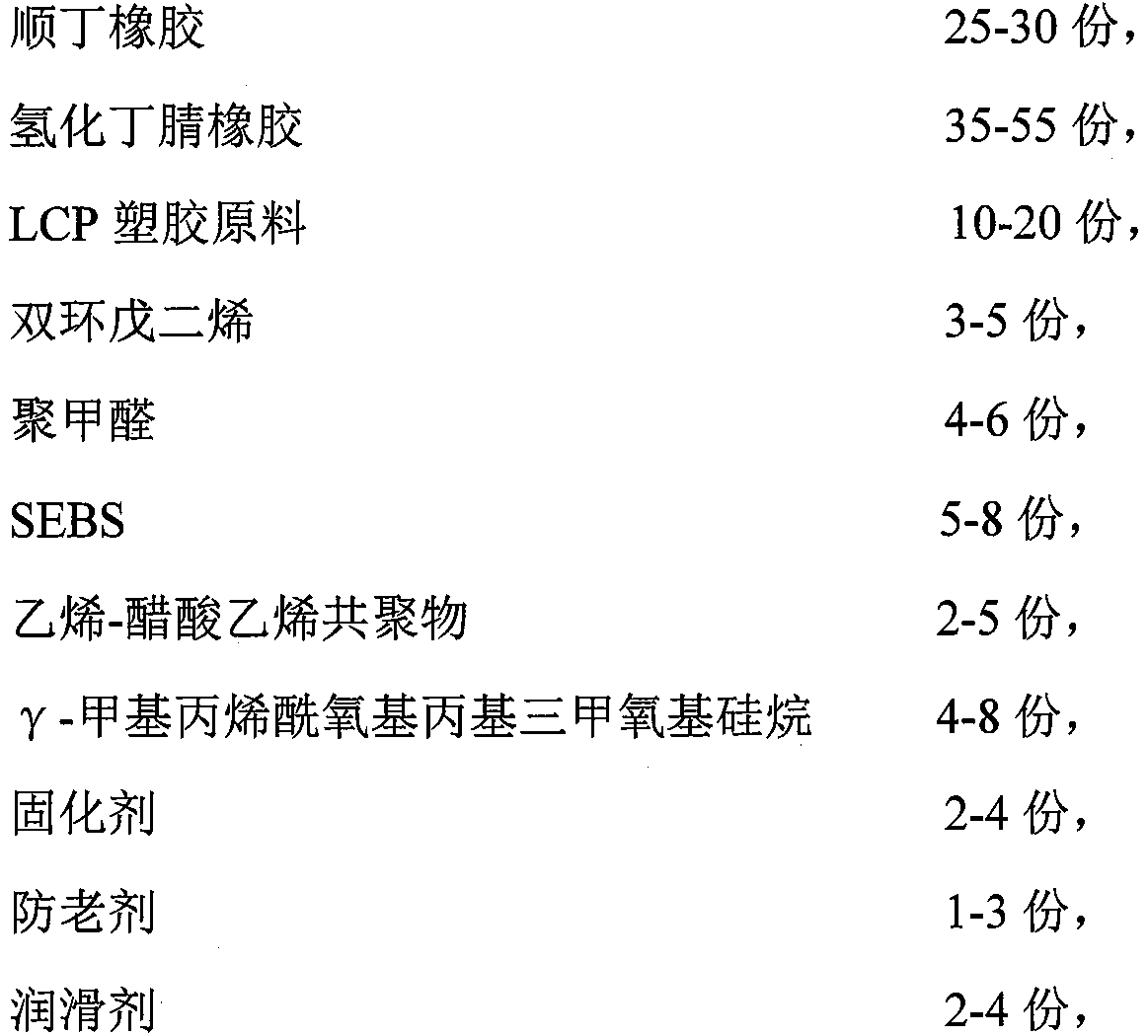

[0039] A novel synchronous belt, the synchronous belt comprises a synchronous belt film, a synchronous belt skeleton and a synchronous belt wrapping layer, wherein the raw materials of the synchronous belt film include the following components by weight:

[0040]

[0041] The skeleton of the synchronous belt includes a cloth cover and a skeleton yarn wound on the cloth cover, and the skeleton yarn is woven from aramid fiber, polyester fiber and glass fiber in a ratio of 1:2:5.

[0042] The preparation method of above-mentioned novel synchronous belt, comprises the steps:

[0043] Hydrogenated nitrile butadiene rubber and butadiene rubber are respectively thinly passed 4 times on the open mill, and then the hydrogenated nitrile butadiene rubber after mastication and butadiene rubber are mixed and thinly passed through for 8 times;

[0044]Add LCP plastic raw materials, dicyclopentadiene, polyoxymethylene, SEBS, ethylene-vinyl acetate copolymer, γ-methacryloxypropyltrimethoxy...

Embodiment 2

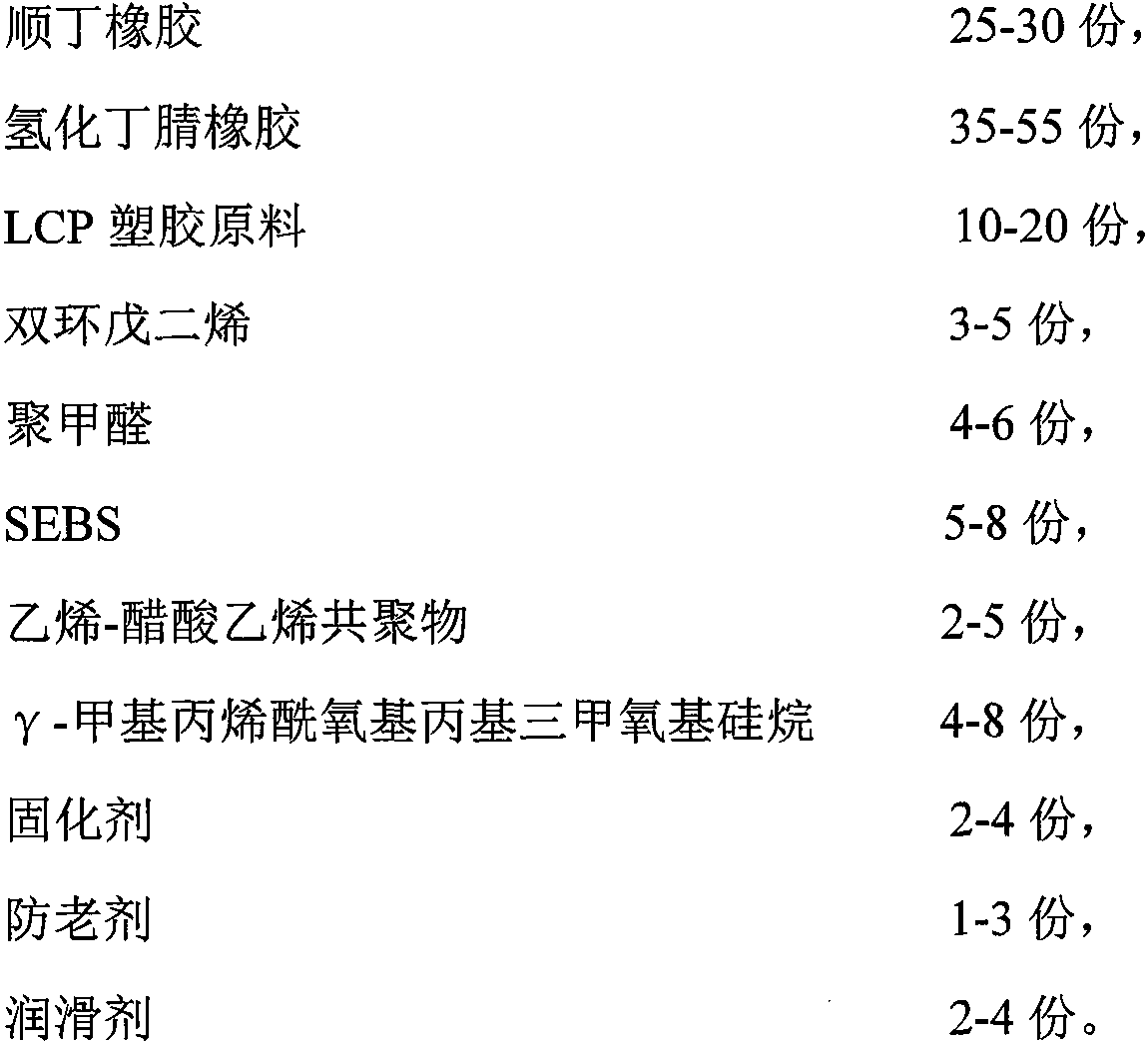

[0056] A novel synchronous belt, the synchronous belt comprises a synchronous belt film, a synchronous belt skeleton and a synchronous belt wrapping layer, wherein the raw materials of the synchronous belt film include the following components by weight:

[0057]

[0058] The skeleton of the synchronous belt includes a cloth cover and a skeleton yarn wound on the cloth cover, and the skeleton yarn is woven from aramid fiber, polyester fiber and glass fiber at a ratio of 1:2:10.

[0059] The preparation method of above-mentioned novel synchronous belt, comprises the steps:

[0060] (1) Preparation of synchronous belt film

[0061] Hydrogenated nitrile butadiene rubber and butadiene rubber are respectively thinly passed 5 times on the open mill, and then the hydrogenated nitrile butadiene rubber after mastication and butadiene rubber are mixed and thinly passed through and beaten triangular bag 10 times;

[0062] Add LCP plastic raw materials, dicyclopentadiene, polyoxymethy...

Embodiment 3

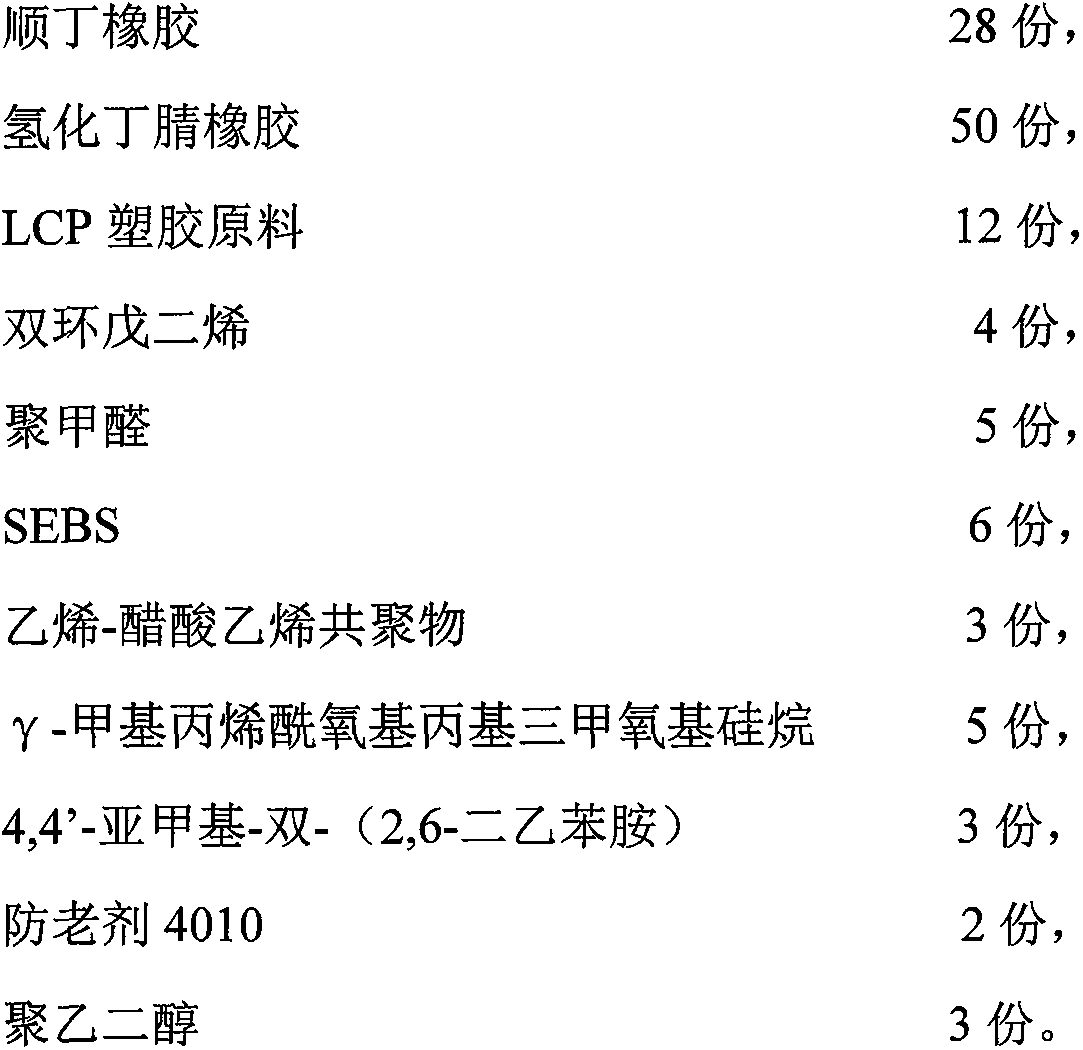

[0074] A novel synchronous belt, the synchronous belt comprises a synchronous belt film, a synchronous belt skeleton and a synchronous belt wrapping layer, wherein the raw materials of the synchronous belt film include the following components by weight:

[0075]

[0076] The skeleton of the synchronous belt includes a cloth cover and a skeleton yarn wound on the cloth cover, and the skeleton yarn is woven from aramid fiber, polyester fiber and glass fiber in a ratio of 2:4:5.

[0077] The preparation method of above-mentioned novel synchronous belt, comprises the steps:

[0078] (1) Preparation of synchronous belt film

[0079] Hydrogenated nitrile butadiene rubber and butadiene rubber are respectively thinly passed 3 times on the open mill, and then the hydrogenated nitrile butadiene rubber after mastication and butadiene rubber are mixed and thinly passed through for 5 times;

[0080] Add LCP plastic raw materials, dicyclopentadiene, polyoxymethylene, SEBS, ethylene-vin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com