Separating and recovering method for cobalt and manganese in cobalt-manganese waste

A technology for separation, recycling, and waste, applied in the direction of improving process efficiency, can solve the problem of cobalt recovery rate of only 70%, and achieve the effect of high recovery rate, high purity, and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

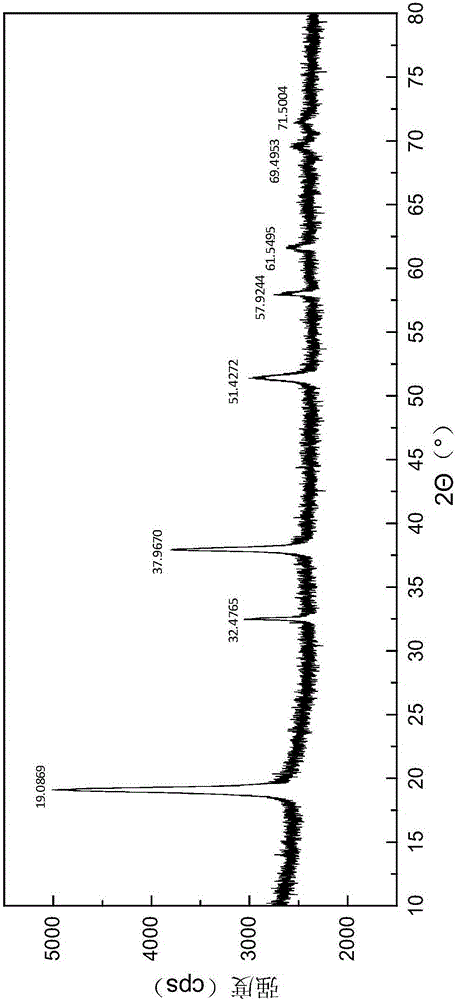

Image

Examples

Embodiment 1)

[0028] The cobalt-manganese waste treated in this example is the waste cobalt-manganese catalyst produced in the production of PTA, wherein the content of cobalt is 9.872wt%, and the content of manganese is 17.12wt%.

[0029] The separation recovery method of cobalt and manganese in the cobalt-manganese waste material of the present embodiment comprises the following steps:

[0030] ① Pretreatment. Take 13 grams of cobalt-manganese waste, and add 30 mL of 40% nitric acid solution to the reaction vessel containing the cobalt-manganese waste. After the cobalt-manganese waste is completely digested, measure the pH value of the acid-dissolved liquid to 1.5. The ratio of the amount of acid to the amount of cobalt-manganese in the spent catalyst is n(H + ):[n(Mn)+n(Co)]=2:1~4:1. Heat the acid-dissolved material with a pH value of less than 3.5 in a water bath at 80°C for 30 minutes, and filter with suction to remove the organic matter in the acid-dissolved material. Need to contr...

Embodiment 2)

[0042] The separation recovery method of cobalt and manganese in the cobalt-manganese waste material of the present embodiment all the other are identical with embodiment 1, difference is:

[0043] After the trivalent cobalt-ammonia complex in step ⑤ is reduced to the divalent cobalt-ammonia complex, add sodium oxalate solution dropwise under stirring, after adding n(C 2 o 4 2- ): n(Co)=8:1~20:1.

[0044] In this embodiment, 150 mL of sodium oxalate solution with a concentration of 50 g / L was added dropwise, the dropping speed was 20 mL / min, and the stirring speed was 500 r / min.

[0045] In addition to the sodium oxalate solution described in this example, ammonium oxalate can also be used instead of sodium oxalate.

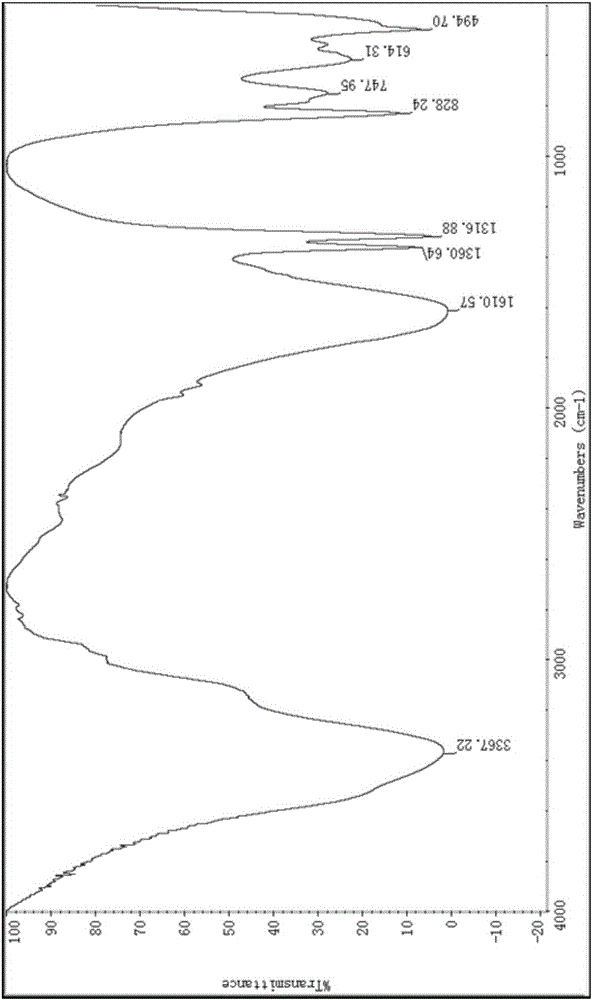

[0046] Obtain 3.08g of cobalt oxalate after drying, the recovery rate of cobalt is 95.25%, and the purity of cobalt oxalate is 98.6%. Cobalt in cobalt-manganese waste is recovered in the form of cobalt oxalate. The infrared spectrogram of the cobalt oxalate ...

Embodiment 3)

[0048] The separation recovery method of cobalt and manganese in the cobalt-manganese waste material of the present embodiment all the other are identical with embodiment 1, difference is:

[0049] Step ① During pretreatment, add 44mL of 10% hydrochloric acid solution to the reaction vessel containing cobalt-manganese waste, and after the cobalt-manganese waste is completely digested, measure the pH value of the acid-dissolved liquid to 4.2. Add 10% hydrochloric acid to the acid-dissolved liquid until the pH drops below 3.5, then transfer to an 80°C water bath and heat for 30 minutes, and filter with suction to remove the organic matter in the acid-dissolved material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com