Special settling agent for tail gas of rural-domestic-garbage incinerator

A technology for domestic waste incineration and sedimentation agent, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., and can solve the problems of substandard gas emission and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0016] A special settling agent for tail gas of rural domestic garbage incinerators, which is made of the following components in parts by weight: 100 parts of tert-butanol, 10 parts of magnetized water, 2 parts of chitosan, 1 part of saponin, and 0.5 parts of watermelon polysaccharide , 3 parts of low-sodium salt, 0.5 parts of wheat oligopeptide, 0.5 part of lutein ester, 0.04 part of armanto flavone, 0.2 part of baicalin, 1.5 parts of softener, 2 parts of water-based resin, 2.5 parts of cationic starch, 2 parts of urea , 0.06 parts of sodium sulfate, 0.06 parts of rare earth oxides;

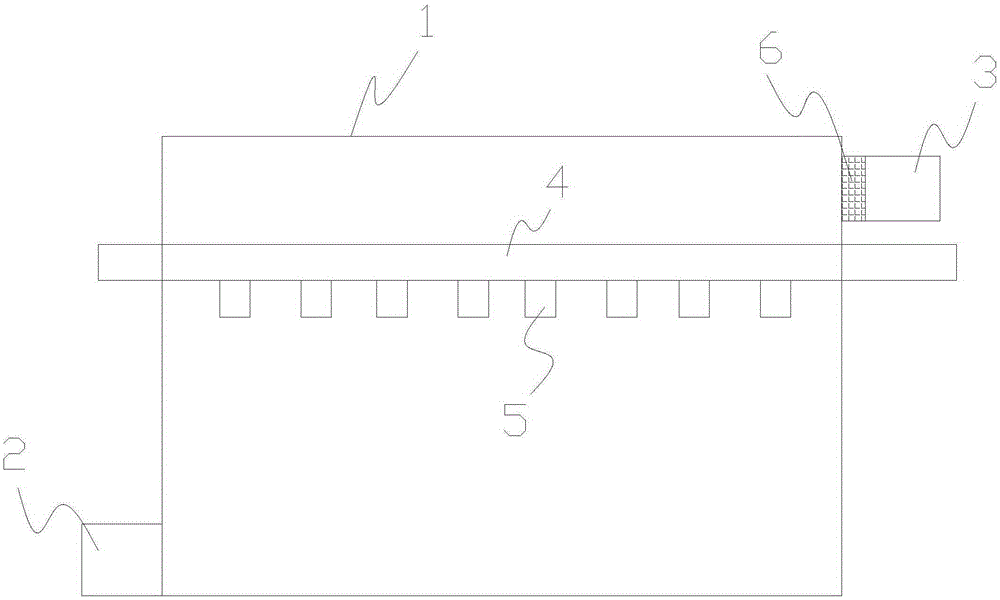

[0017] Such as figure 1 As shown, a settling box for an incinerator containing the above-mentioned settling agent includes a settling box 1 with a cavity, one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com