Hyperdispersed antibacterial nanodiamond material and preparation method thereof

A nano-diamond and ultra-dispersion technology, which is applied in the field of diamond processing, can solve problems such as complicated steps and processes, changing the dispersion characteristics of nano-diamond, etc., and achieve the effect of easy-to-obtain raw materials, high yield, and broaden the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of ultra-dispersed antibacterial nano-diamond material of the present invention, comprises the following steps:

[0025] a. Mechanically grinding the raw nano-diamond powder to obtain a nano-diamond aggregate with uniform particle size;

[0026] b. Dispersing the ground nano-diamonds in an ethanol solution;

[0027] c. add silane coupling agent 3-bromopropyltrimethoxysilane to the nano-diamond ethanol solution obtained in step b to react, wash, separate and dry after the reaction to obtain silanized nano-diamond;

[0028] d. Dispersing silanized nano-diamonds in a solvent, adding polytetravinylpyridine and brominated alkanes for reaction, precipitating and washing the reaction product with ether, centrifuging and drying to obtain the final product of quaternized nano-diamonds.

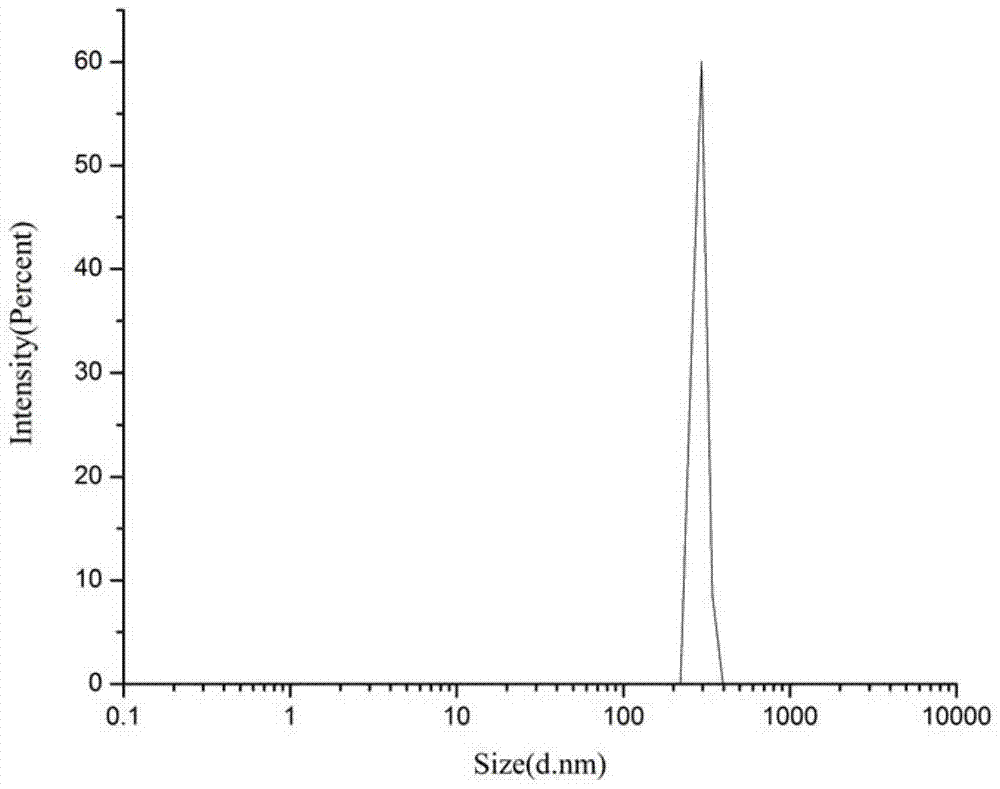

[0029] Preferably, the raw nano-diamond powder in step a is obtained by detonation method, and the hydrated particle size is 350.3nm. In step a, the larger nano-diamond ...

Embodiment 1

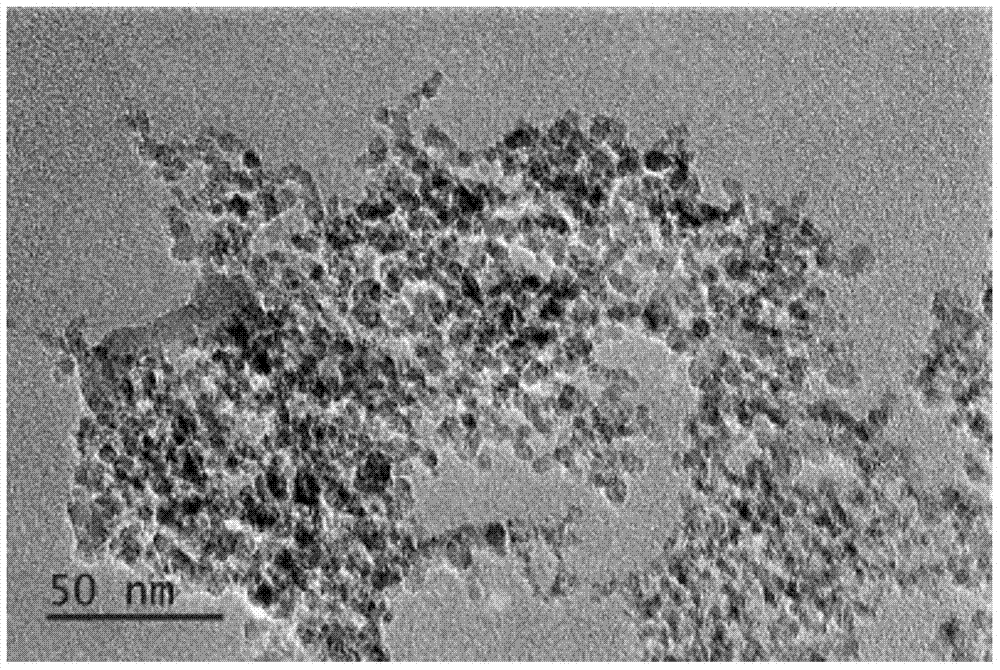

[0037] Step a: Mechanically grind the nano-diamonds with a mortar to disperse the larger aggregates into small aggregates with a relatively uniform particle size, and characterize it through a transmission electron microscope and a dynamic light scattering particle size analyzer, such as figure 1 and figure 2 , hydrated particle size 350.3nm;

[0038] Step b: Weigh 2 g of ground nano-diamonds and disperse them in 100 mL of 80% ethanol solution;

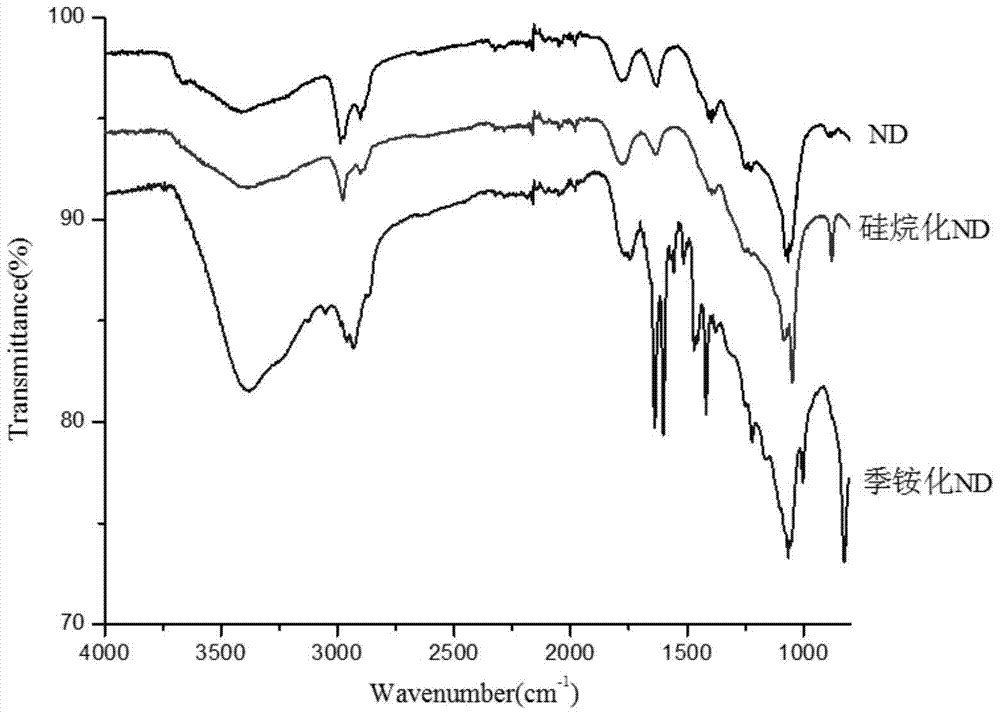

[0039] Step c: Add 3-bromopropyltrimethoxysilane of 5% nano-diamond mass to the above system, react at 40°C for 16 hours, wash with ethanol, filter and dry to obtain silanized nano-diamonds, which are analyzed by infrared representation, such as image 3 ;

[0040] Step d: Weigh 60 mg of silanized nano-diamonds and disperse them in the solvent nitromethane, add 0.3 g of polytetravinylpyridine and 0.12 g of hexyl bromide (silanized nano-diamonds: polytetravinyl pyridine: hexyl bromide=1: 5:2) After reacting at a temperature of 50°...

Embodiment 2

[0045] Step b: an ethanol solution with a mass fraction of 80%;

[0046] Step c: adding 3-bromopropyltrimethoxysilane with 5% nano-diamond mass to the nano-diamond ethanol solution obtained in step b to react for 16 hours at a reaction temperature of 40° C.;

[0047] Step d: The solvent is nitromethane, silanized nano-diamond:polytetravinylpyridine:bromohexane=1:5:0, the reaction temperature is 50°C, and the reaction is 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com