Compound organic fertilizer and preparation method thereof

An organic fertilizer and raw material technology, applied in the field of compound organic fertilizer and its preparation, can solve the problems of inconvenient fertilization, short fertilizer effect time, high manufacturing cost, etc., and achieve the effects of improving fertility, maintaining odor, and maintaining fertilizer effect time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

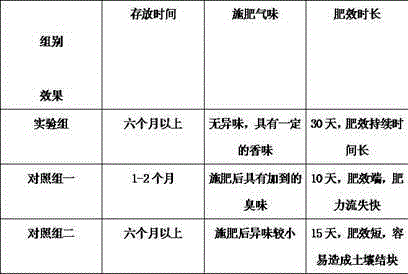

Image

Examples

Embodiment 1

[0022] A compound organic fertilizer and a preparation method thereof, comprising the following proportions by weight: 15 parts of sodium bicarbonate, 15 parts of potassium alum, 10 parts of calcium carbonate, 6 parts of vanillin, 14 parts of halloysite, and 8 parts of limestone , 20 parts of Zongba leaves, 25 parts of sorrel, 30 parts of coconut shells, 40 parts of soybean shells, 20 parts of furfural residues, 15 parts of soy sauce residues, 12 parts of grape skins, 9 parts of sodium humate and 15 parts of Necklace algae.

[0023] A preparation method of compound organic fertilizer, comprising the following steps:

[0024] 1) Put 15 parts of sodium bicarbonate, 15 parts of potassium alum, 10 parts of calcium carbonate, 6 parts of vanillin, 14 parts of halloysite and 8 parts of limestone into the reactor, keep the temperature at 45-50 ° C, and react 2 -3 hours, standby;

[0025] 2) Put the raw materials obtained in step 1) into the crusher, process the 40-mesh powder and pou...

Embodiment 2

[0032] A compound organic fertilizer and a preparation method thereof, comprising the following proportions by weight: 20 parts of sodium bicarbonate, 10 parts of potassium alum, 8 parts of calcium carbonate, 4 parts of vanillin, 12 parts of halloysite, and 6 parts of limestone , 18 parts of Zongba leaves, 22 parts of sorrel, 25 parts of coconut shells, 35 parts of soybean shells, 18 parts of furfural residues, 12 parts of soy sauce residues, 10 parts of grape skins, 7 parts of sodium humate and 12 parts of Necklace algae.

[0033] A preparation method of compound organic fertilizer, comprising the following steps:

[0034] 1) Put 20 parts of sodium bicarbonate, 10 parts of potassium alum, 8 parts of calcium carbonate, 4 parts of vanillin, 12 parts of halloysite and 6 parts of limestone into the reactor, keep the temperature at 45-50 ° C, and react 2 -3 hours, standby;

[0035] 2) Put the raw materials obtained in step 1) into the crusher, process the 40-mesh powder and pour ...

Embodiment 3

[0042]A compound organic fertilizer and a preparation method thereof, comprising the following proportions by weight: 17.5 parts of sodium bicarbonate, 12.5 parts of potassium alum, 9 parts of calcium carbonate, 5 parts of vanillin, 13 parts of halloysite, and 7 parts of limestone , 19 parts of Zongba leaves, 23.5 parts of sorrel, 27.5 parts of coconut shells, 37.5 parts of soybean shells, 19 parts of furfural residue, 13.5 parts of soy sauce residue, 11 parts of grape skin, 8 parts of sodium humate and 13.5 parts of anchovies.

[0043] A preparation method of compound organic fertilizer, comprising the following steps:

[0044] 1) Put 17.5 parts of sodium bicarbonate, 12.5 parts of potassium alum, 9 parts of calcium carbonate, 5 parts of vanillin, 13 parts of halloysite and 7 parts of limestone into the reactor, keep the temperature at 45-50 ° C, and react 2 -3 hours, standby;

[0045] 2) Put the raw materials obtained in step 1) into the crusher, process the 40-mesh powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com