Graphene-containing wear-resisting fluororubber and preparation method thereof

A technology of fluororubber and graphene, which is applied in the field of composite materials, can solve problems such as poor stability, complicated process, and no wear-resistant effect, and achieve good wear-resistant effect, improved wear-resistant performance, excellent gas barrier performance and heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The wear-resistant fluororubber material consists of 100 parts by mass of fluororubber, 10 parts of graphene, 0.05 parts of nano-diamond powder, 5 parts of acid absorbing agent, and 5 parts of carbon black.

[0029] Add fluororubber, graphene, nano-diamond powder, acid absorbing agent and carbon black into the internal mixer, and banbury at 60°C for 100min.

[0030] Then, the nanocomposite blend and the vulcanizing agent are uniformly mixed on a two-roller rubber mixing machine, and vulcanized on a flat vulcanizing machine to obtain a wear-resistant fluororubber material. The fluororubber is subjected to various performance tests according to the corresponding national standards.

Embodiment 2

[0032] The wear-resistant fluororubber material consists of 100 parts by mass of fluororubber, 20 parts of graphene, 5 parts of nano-diamond powder, 5 parts of acid absorbing agent, and 5 parts of white carbon black.

[0033] Add fluororubber, graphene, nano-diamond powder, acid absorbing agent and carbon black into the internal mixer, and banbury at 60°C for 100min.

[0034] Then, the nanocomposite blend and the vulcanizing agent are uniformly mixed on a two-roller rubber mixing machine, and vulcanized on a flat vulcanizing machine to obtain a wear-resistant fluororubber material. The nano-composite material is subjected to various performance tests according to the corresponding national standards.

Embodiment 3

[0036] The wear-resistant fluororubber material consists of 100 parts by mass of fluororubber, 0.05 parts of graphene, 15 parts of nano-diamond powder, 5 parts of acid absorbing agent, 10 parts of carbon black, and 5 parts of white carbon black.

[0037] Add fluorine rubber, graphene, nano-diamond powder, acid absorbing agent, carbon black and white carbon black into the internal mixer, and banbury at 60°C for 100 minutes.

[0038] Then, the nanocomposite blend and vulcanization system components are uniformly mixed on a two-roller rubber mixer, and vulcanized on a flat vulcanizer to obtain a wear-resistant fluororubber material. The nano-composite material is subjected to various performance tests according to the corresponding national standards.

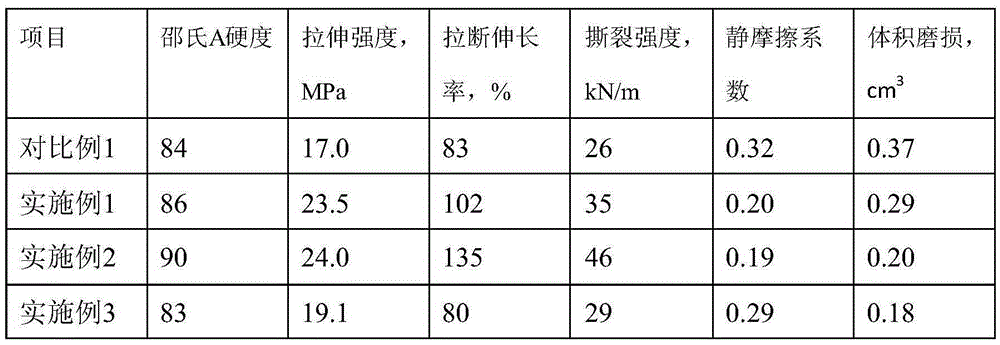

[0039] Table 1 is the physical and mechanical properties of the examples. It can be seen from Table 1 that the wear-resistant fluororubber material of the present invention has more excellent mechanical properties and wear resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com