Polyurethane pouring sealant and preparation method thereof

A potting glue and polyurethane technology, applied in the field of polyurethane potting glue and its preparation, can solve the problems of weak metal adhesion, long curing time, poor transparency, etc., achieve fast curing speed, reduce construction process requirements, and be easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

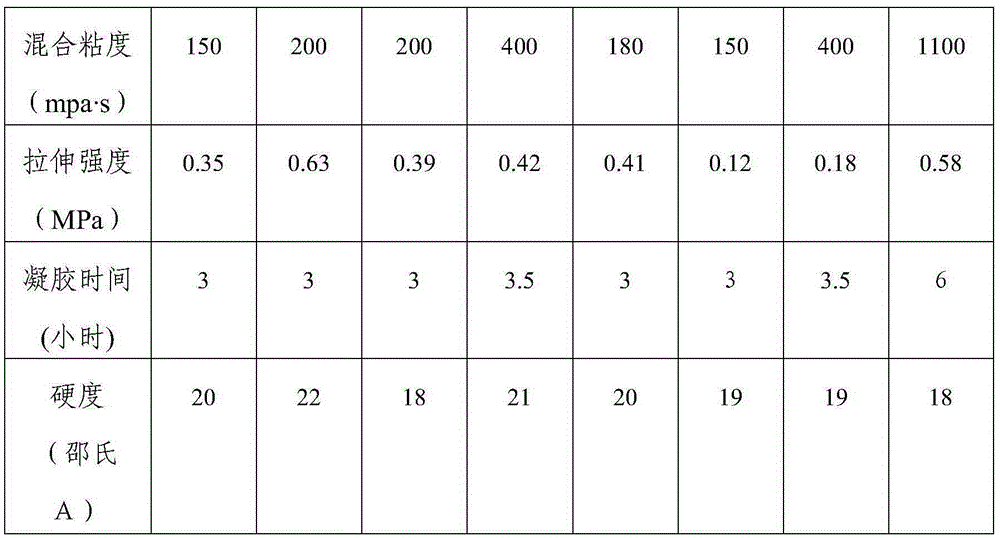

Embodiment 1

[0029] The present invention will be further described below in conjunction with the examples, which are not limited to the present invention.

[0030] The following examples are all in weight percent.

[0031] Embodiment 1 A kind of polyurethane potting glue (A component does not contain plasticizer)

[0032] A polyurethane potting glue, comprising the steps of:

[0033] (1) Component A is made from the following components by weight:

[0034] Add 90.5 parts of castor oil, 2 parts of 1,4-butanediol, 3 parts of triethanolamine, 10100.5 parts of antioxidant, 0.5 parts of UV-3280, and 6220.5 parts of light stabilizer into the reaction kettle, and stir at 80-100 °C, Vacuumize and dehydrate and degas for 3 hours, lower the temperature to 10-40°C, add 2 parts of organic rare metal catalyst PD, 40.5 parts of defoamer BYK17940, and 20.5 parts of coupling agent PN-7920, stir evenly, and discharge.

[0035] (2) B component is made from the following components by weight:

[0036] A...

Embodiment 2

[0038] Embodiment 2 A kind of polyurethane potting glue (A component does not contain plasticizer)

[0039] A polyurethane potting glue, comprising the steps of:

[0040] (1) Component A is made from the following components by weight:

[0041] Add 90.5 parts of castor oil, 2 parts of 1,4-butanediol, 3 parts of triethanolamine, 10100.5 parts of antioxidant, 0.5 parts of UV-3280, and 6220.5 parts of light stabilizer into the reaction kettle, and stir at 80-100 °C , vacuum dehydration and degassing for 3.5 hours, lower the temperature to 10-40°C, add 16192 parts of organic bismuth zinc catalyst, 10.2 parts of defoamer BYK1410.3 parts, DeFom65000.3 parts, coupling agent KH-5500.5 parts, stir evenly, discharge .

[0042] (2) B component is made from the following components by weight:

[0043] Add 52 parts of dioctyl phthalate into the reaction kettle, vacuumize and dehydrate at 80-100°C for 2-3 hours to make the water content <0.05%, drop the temperature to 10-30°C, add 32 par...

Embodiment 3

[0045] Embodiment 3 A kind of polyurethane potting glue (A component does not contain plasticizer)

[0046] A polyurethane potting glue, comprising the steps of:

[0047] (1) Component A is made from the following components by weight:

[0048] 79.5 parts of castor oil, 10 parts of polyoxypropylene glycol (Mn1000), 2 parts of 1,4-butanediol, 3 parts of trimethylolpropane, 10100.5 parts of antioxidant, 0.5 parts of UV-3280, 6220.5 parts of light stabilizer Add 3 parts of stannous octoate, 0.5 parts of antifoaming agent BYK17900, and 0.5 parts of coupling agent KH-5600.5 portion, stir evenly, and discharge.

[0049](2) B component is made from the following components by weight:

[0050] Add 61.3 parts of dioctyl phthalate into the reaction kettle, vacuumize and dehydrate at 80-100°C for 2-3 hours to make the water content <0.05%, cool down to 10-30°C, add 20.5 parts of toluene diisocyanate, pre- 15.6 parts of polymer ZB1895 and 5052.6 parts of polymethylene polyphenyl polyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com