Refrigerating machine oil composition and application thereof

A technology of refrigeration oil and composition, applied in lubricating composition, petroleum industry and other directions, can solve the problems of valve plate and piston corrosion, affecting the service life and efficiency of refrigeration compressors, poor viscosity-temperature performance, etc., to prevent acid and oil contamination, etc. , the effect of excellent oxidation stability, excellent viscosity-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

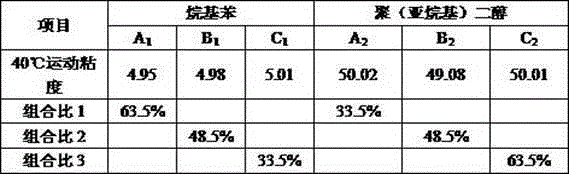

Embodiment 1

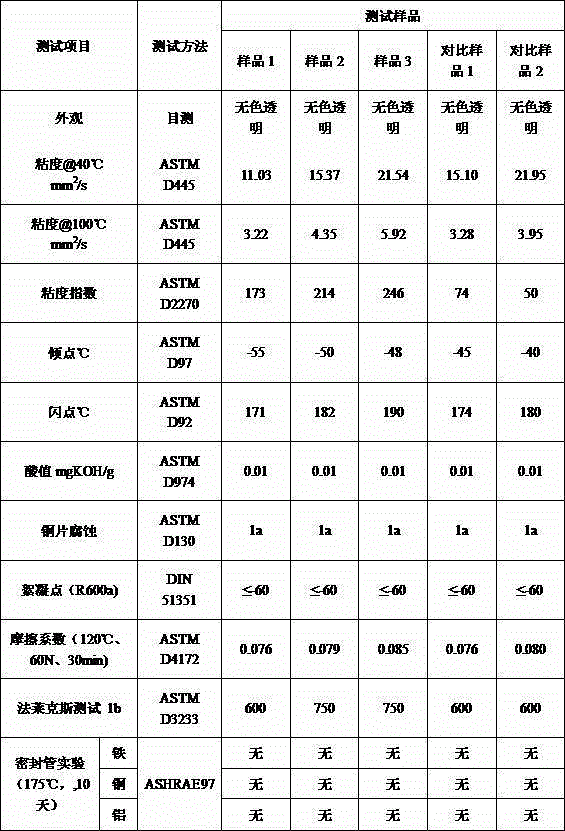

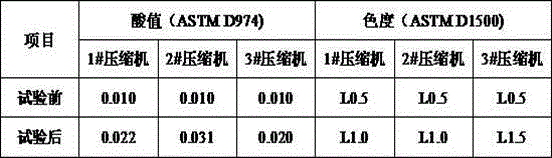

[0037] The component content of the refrigerating machine oil composition described in Example 1 is: select a combination ratio of 1, 1.6% of triphenyl phosphate extreme pressure antiwear agent, 0.298% of phenyl-β-naphthylamine antioxidant, 1% of Ethylene glycol oleate oily agent, 0.1% N,N~dialkylaminomethylene benzotriazole corrosion inhibitor, 0.002% simethicone antifoam agent, mix the above raw materials evenly, heat to 45 About ℃, 0.5×10 -3 Vacuum dehydration under Pa, about 3 hours. Test the moisture content of the refrigerating machine oil. If the moisture content is lower than 20ppm, the sample is qualified and sealed to make sample 1.

Embodiment 2

[0038] The component content of the refrigerating machine oil composition described in Example 2 is: select a combination ratio of 2, 1.6% of triphenyl phosphate extreme pressure antiwear agent, 0.298% of phenyl-β-naphthylamine antioxidant, 1% of Ethylene glycol oleate oily agent, 0.1% N,N~dialkylaminomethylene benzotriazole corrosion inhibitor, 0.002% simethicone antifoam agent, mix the above raw materials evenly, heat to 45 About ℃, 0.5×10 -3 Vacuum dehydration under Pa, about 3 hours. Test the moisture content of the refrigerating machine oil. If the moisture content is lower than 20ppm, the sample is qualified and sealed to make sample 2.

Embodiment 3

[0039] The component content of the refrigerating machine oil composition described in Example 3 is: select a combination ratio of 3, 1.6% of triphenyl phosphate extreme pressure antiwear agent, 0.298% of phenyl-β-naphthylamine antioxidant, 1% of Ethylene glycol oleate oily agent, 0.1% N,N~dialkylaminomethylene benzotriazole corrosion inhibitor, 0.002% simethicone antifoam agent, mix the above raw materials evenly, heat to 45 About ℃, 0.5×10 -3 Vacuum dehydration under Pa, about 3 hours. Test the moisture content of the refrigerating machine oil. If the moisture content is lower than 20ppm, the sample is qualified and sealed to make sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com