Method for preparing high-purity xylo-oligosaccarides by taking cottonseed hulls as raw materials

A technology for xylo-oligosaccharides and cottonseed hulls, which is applied in the direction of fermentation and the like, can solve the problems affecting the cost and efficiency of xylo-oligosaccharides from cottonseed hulls, increase the cost of preparing high-purity xylo-oligosaccharides, and affect the preparation efficiency, etc. Product purity, reducing usage and enzymatic hydrolysis time, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Relation between cooking temperature and xylose monosaccharide content in cooking liquid

[0033] Get cottonseed hulls Get 450g of cottonseed hulls, mix with process water in a mass ratio of 1:8, divide into the following conditions and cook the cottonseed hulls:

[0034] Cooking condition 1: without adding acetic acid catalyst, cook at 165°C for 60 minutes;

[0035] Cooking condition 2: adding acetic acid with a percentage of dry weight of cottonseed hulls of 0.8%, cooking at 165°C for 60mim;

[0036] Cooking condition 3: adding acetic acid with a percentage of dry weight of cottonseed hulls of 0.8%, cooking at 135°C for 60mim;

[0037] Cooking condition 4: add acetic acid with a percentage of dry weight of cottonseed hulls of 0.8%, and cook at 180°C for 60 minutes;

[0038] Cooking condition 5: add acetic acid with a percentage of dry weight of cottonseed hulls of 0.8%, and cook at 165°C for 30 minutes;

[0039] Cooking condition 6: add acetic acid wi...

Embodiment 2

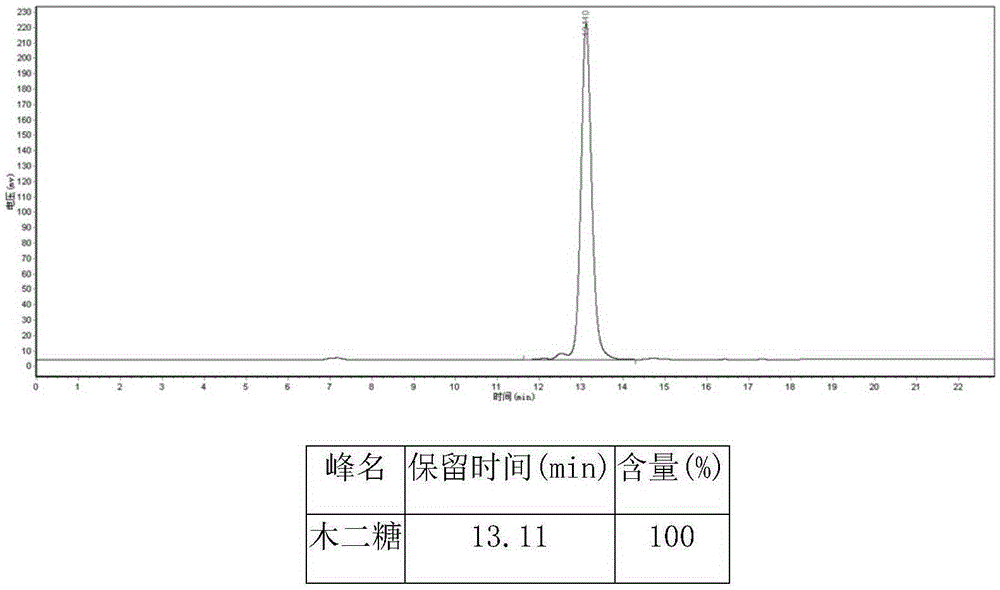

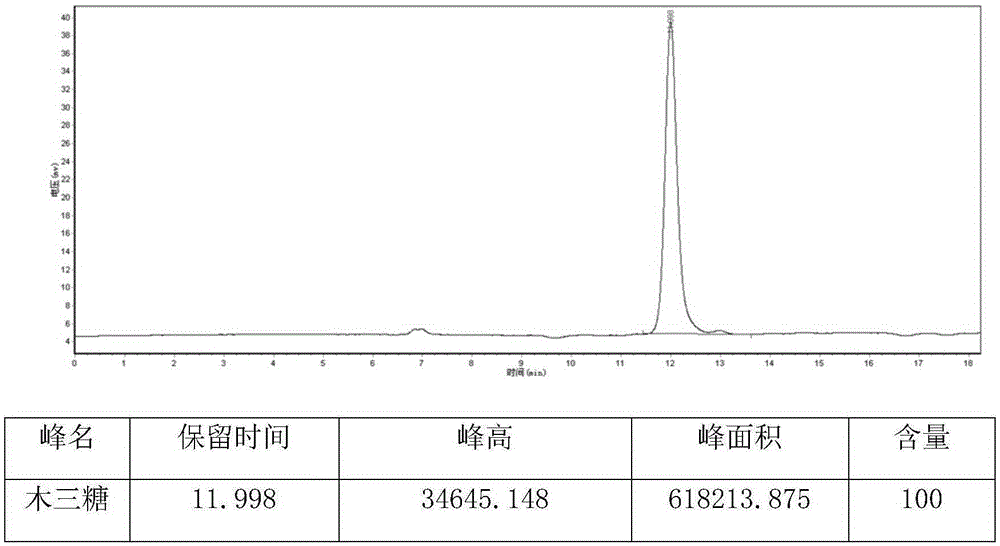

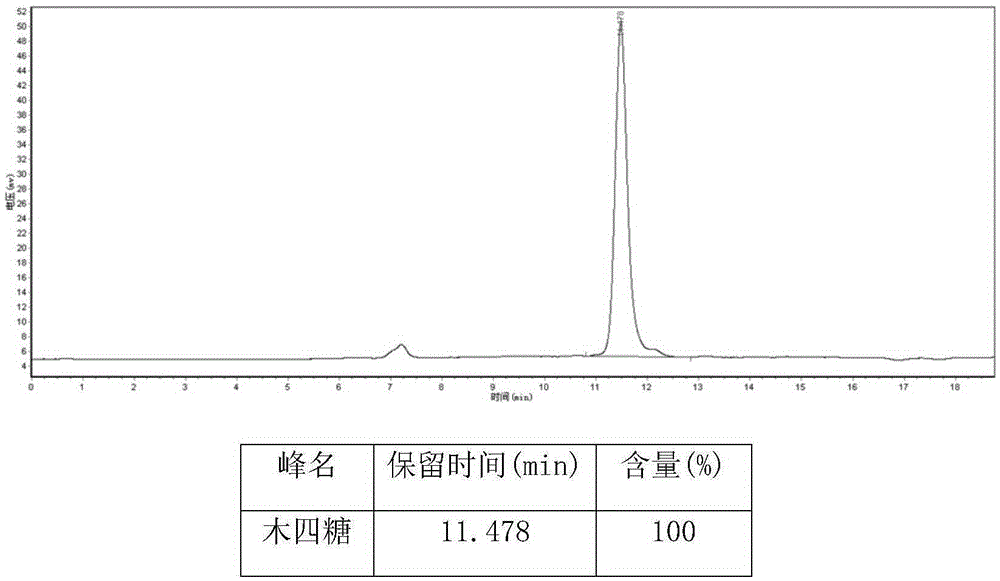

[0042] Embodiment 2: Xylose monosaccharide content corresponding product xylobiose-xylheptaose component situation in cooking liquid

[0043] Under different cooking conditions, 0.08g Xiasheng xylanase SPE-01XG was added to the cooking liquid, the enzymatic hydrolysis reaction temperature was 70°C, and the enzymatic hydrolysis time was 8 hours. The product components are shown in the table below:

[0044] Xylose content in cooking liquor (%)

[0045] 12.79

Embodiment 3

[0046] Embodiment 3 cottonseed hulls prepare high-purity xylo-oligosaccharides

[0047] Take 450 g of cottonseed hulls, mix them with process water at a mass ratio of 1:8, add acetic acid with a dry weight percentage of cottonseed hulls of 0.8%, and cook at 165°C for 60 minutes to dissolve xylan in cottonseed hulls and control the amount of acetic acid in the cooking liquid. The xylose content is 5.23%, and the temperature is lowered for use; add 0.08g Xiasheng xylanase SPE-01XG to the cooking liquid, the enzymatic hydrolysis reaction temperature is 70°C, and the enzymatic hydrolysis time is 8h. Xylooligosaccharide syrup with a xylobiose-xyloheptaose purity of 91.43% was prepared (see Table 1 for specific components).

[0048] Table 1: Content table of each component of high-purity xylo-oligosaccharide

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com